Method for measuring residual stress of thin plating layer based on surface ultrasonic waves

A technology of residual stress and thin coating, which is applied in the field of measurement, can solve problems such as the inability to detect residual stress of coated products, and achieve the effects of avoiding hidden dangers in quality and safety, fast detection speed, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

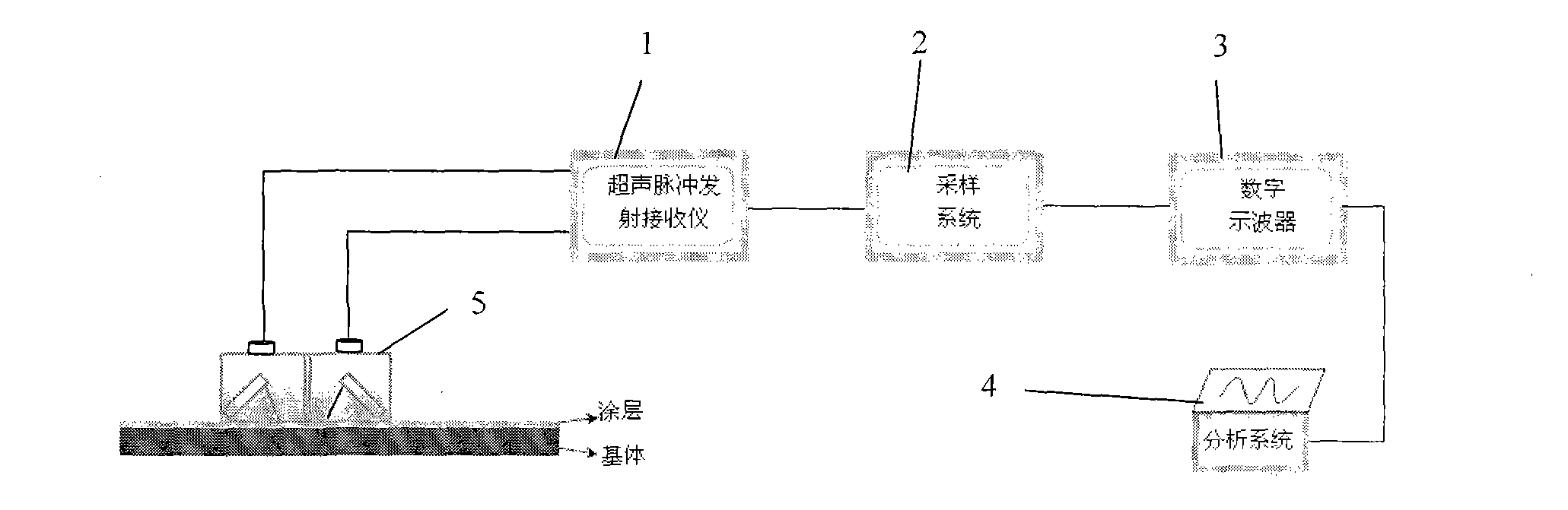

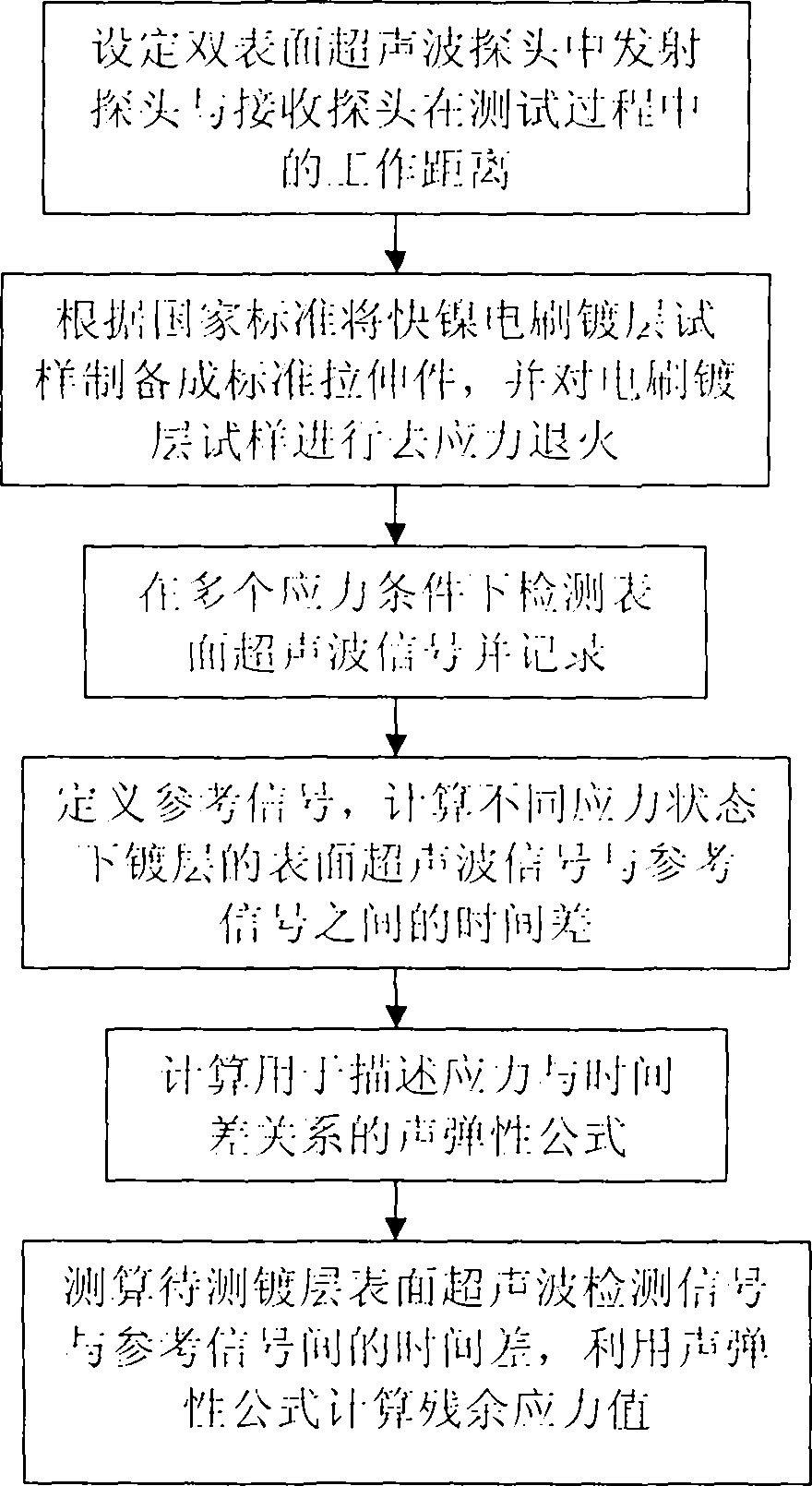

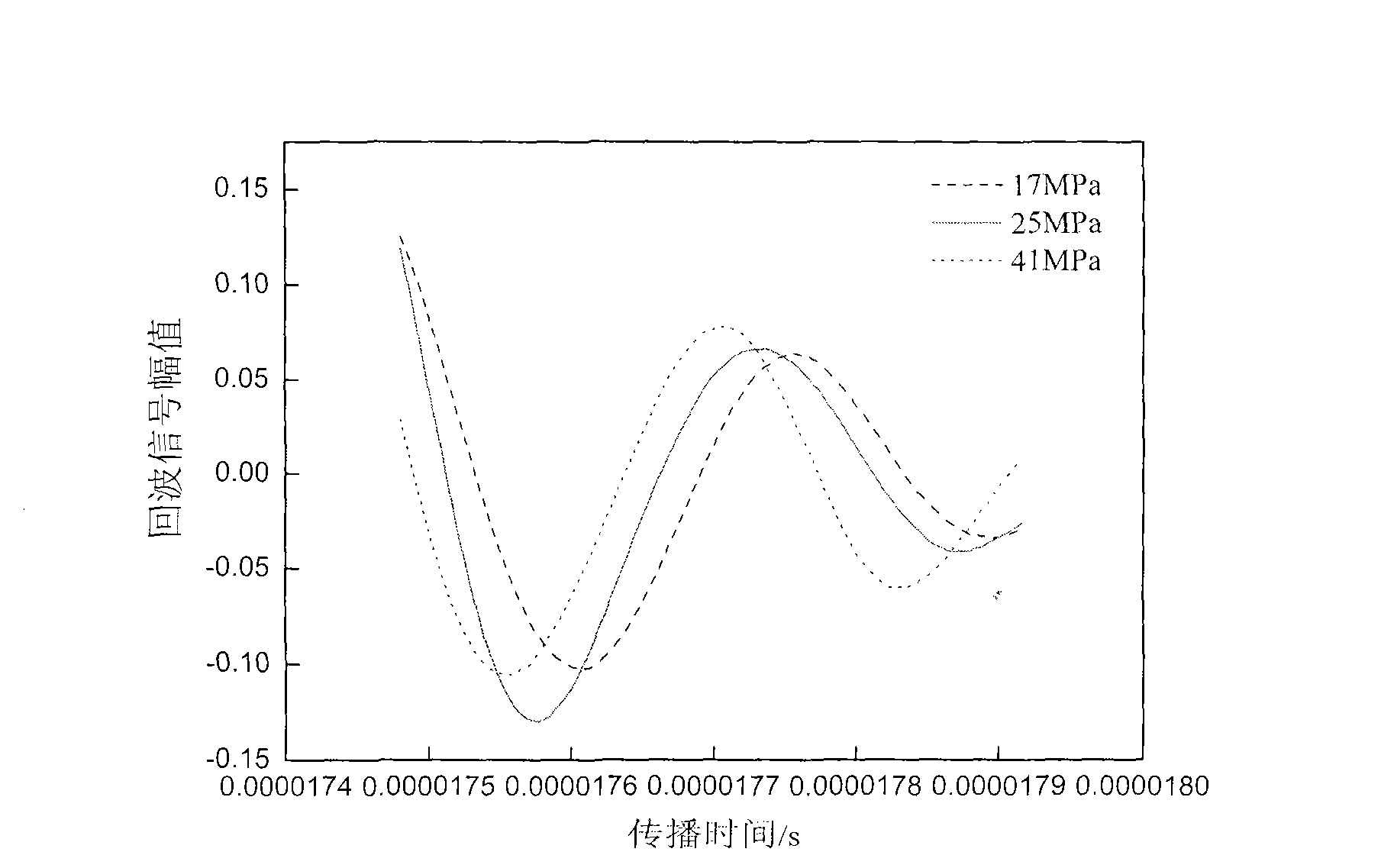

[0030] The important reason for the failure of the coating is the cracking and delamination of the coating caused by the surface stress. Therefore, the damage degree of the coating can be evaluated by detecting the residual stress of the coating. In the present invention, surface ultrasonic waves are used to measure stress, which is a method for measuring medium surface stress on the basis of the theory of acoustoelastic effect, that is, the evaluation of medium surface stress is realized by measuring sound velocity. In view of the difficulty of accurately measuring the propagation velocity of the surface ultrasonic wave in the coating, the present invention turns to calculate the time difference that the surface ultrasonic wave passes through the same distance in the coating, that is, the time difference and the stress that the surface ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com