High-speed visual on-line detection equipment for surface defects of steel rails

A technology for testing equipment and rails, applied in the direction of optical testing flaws/defects, etc., can solve the problems of staying visual detection algorithm, device description, unpublished and other problems, and achieve the effects of fast detection speed, simple operation and easy application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

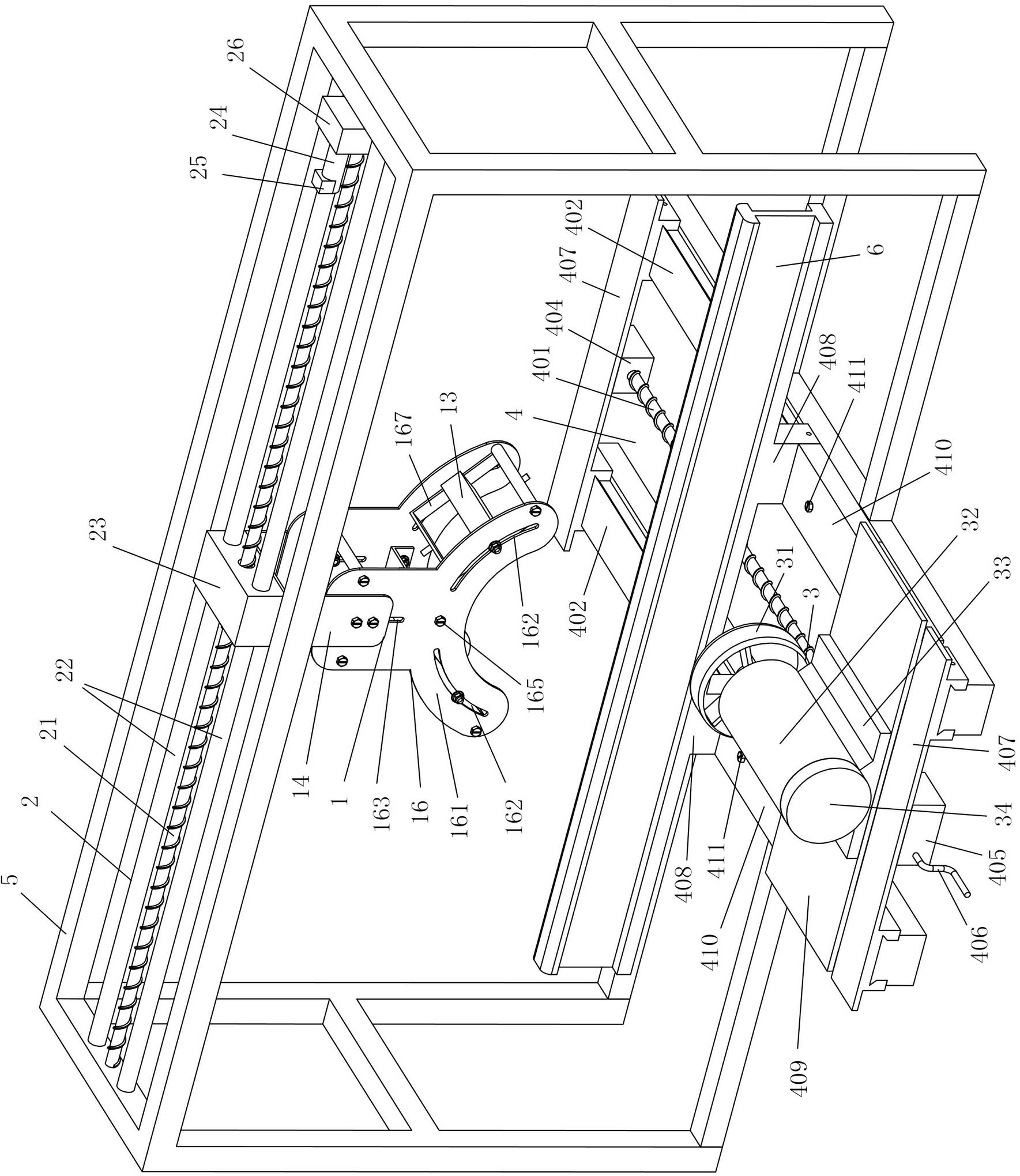

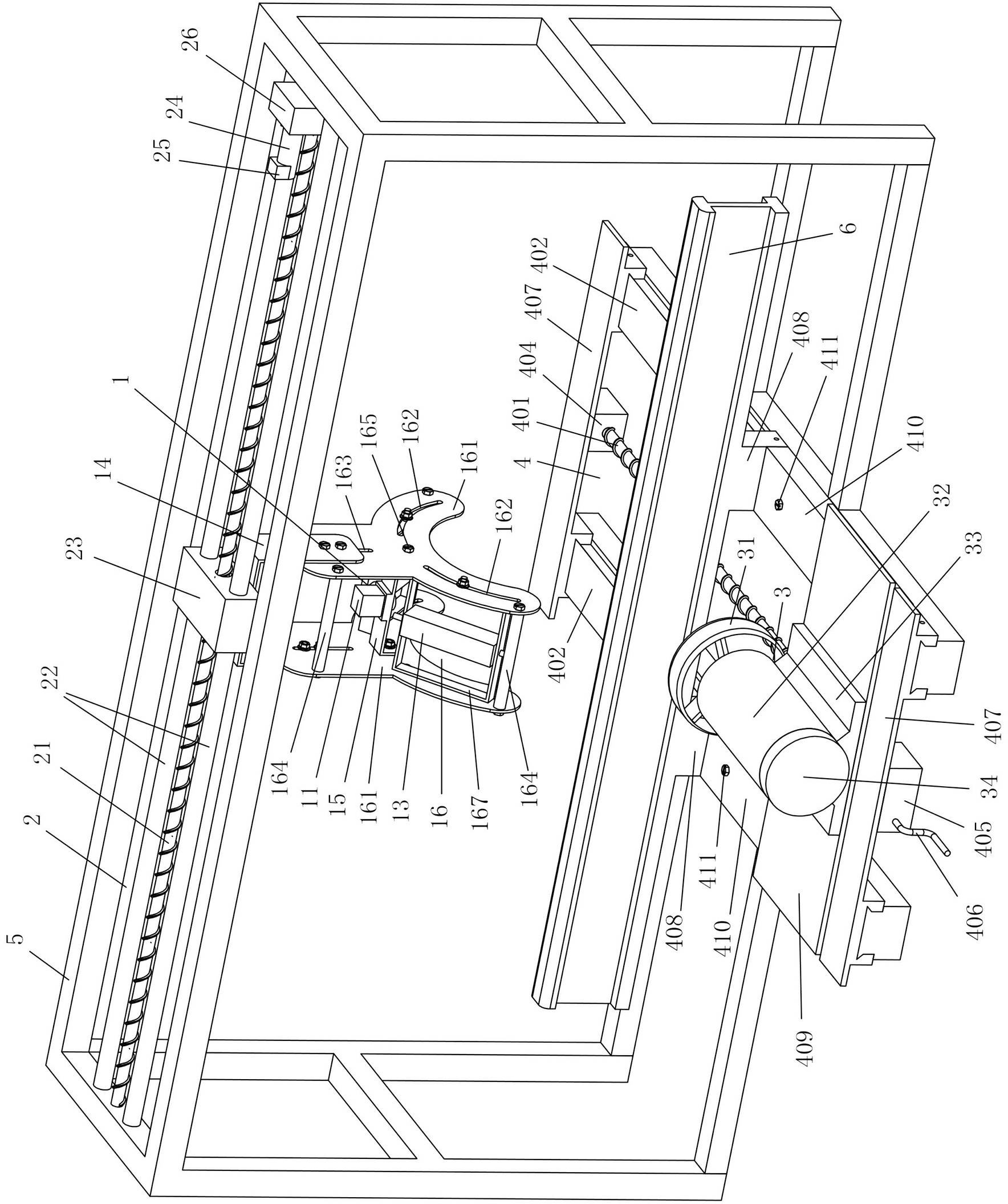

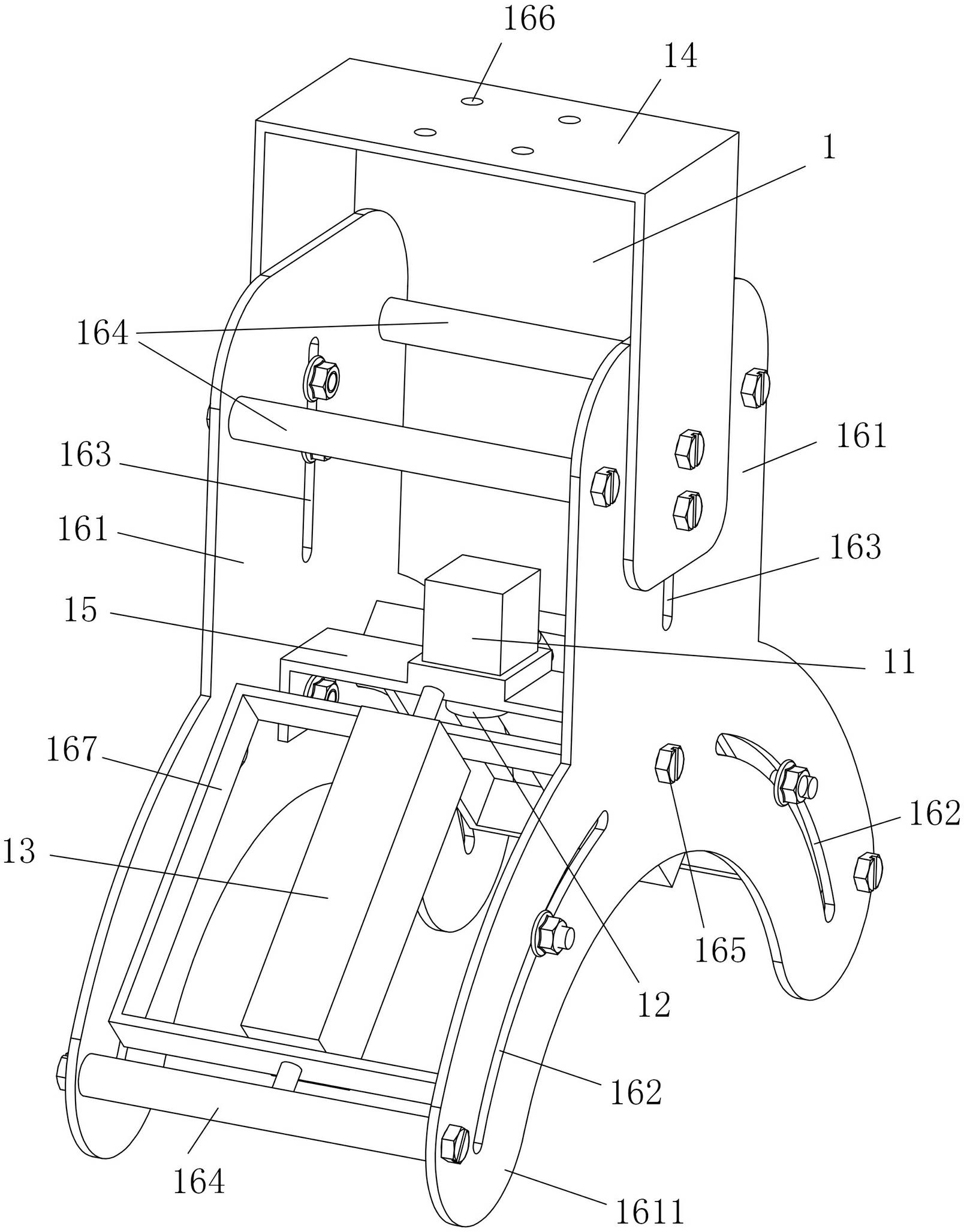

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] Such as figure 1 and figure 2As shown, the high-speed visual online detection equipment for rail surface defects of the present invention includes an imaging system 1, a low-speed parallel rail moving device 2, a high-speed rotating device 3, a high-low speed switching device 4, a bracket 5, a rail 6 and a control system (not shown in the figure) Shown), the control system includes encoder control camera acquisition frequency system, industrial computer, electrical control system, disk array storage system. Among them, the imaging system 1 is installed on the low-speed parallel rail moving device 2, and the high-speed rotating device 3 includes a high-speed rotating disk 31, the upper surface of the high-speed rotating disk 31 is at the same level as the rail surface of the rail 6, and the rail 6 and the high-speed rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com