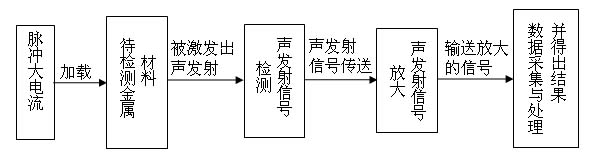

Electromagnetic acoustic emission non-destructive detection method and device of metal material

A metal material, non-destructive testing technology, applied in the direction of material magnetic variables, etc., can solve problems such as secondary damage, and achieve the effects of low price, expanded application scope, and simple structure of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

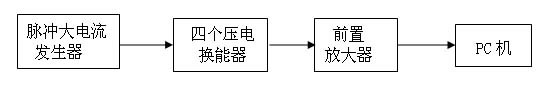

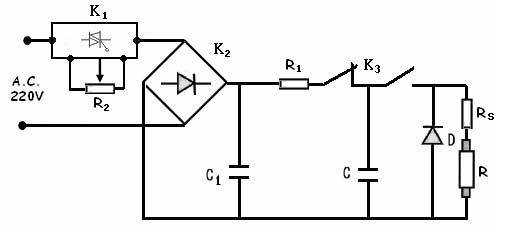

Embodiment 1

[0032] When starting the test, connect the pulse large current generator to 220v AC. When the charging voltage of the high-voltage capacitor C reaches 50V, the peak value of its discharge current can reach 800A, and the pulse width is 220 microseconds. Pass this pulse large current through 1.5 square meters The millimeter copper wire input is loaded on the aluminum metal material to be detected with a size of 500mm×115mm×15mm, and the aluminum metal material to be detected is excited to generate an acoustic emission signal, and the signal is placed on the aluminum metal material to be detected in a rhombus position The four piezoelectric sensors of R15a type on the board detect and input the preamplifier of American PAC company model 2 / 4 / 6 through the signal line, and the acoustic emission signal is amplified by the preamplifier and input to the PC. The collected acoustic emission signals are used for two-dimensional time-difference positioning, and the calculation steps are as...

Embodiment 2

[0037] In addition to starting the detection, connect the pulse large current generator to 220v AC. When the charging voltage of the high-voltage capacitor C reaches 50V, the peak value of the discharge current can reach 1860A, and the pulse width is 250 microseconds. The metal material to be detected is a size of Except for the alloy steel metal material of 500mm×115mm×15mm, the others are the same as in Embodiment 1.

[0038] Finally, the position of the crack-type defect in the alloy steel metal material to be detected was detected with a positioning error of 1mm.

Embodiment 3

[0040] In addition to starting the detection, connect the pulse large current generator to 220v alternating current. When the charging voltage of the high-voltage capacitor C reaches 50V, the peak value of the discharge current can reach 3000A, and the pulse width is 300 microseconds. The metal material to be detected is a size of Except for the alloy steel metal material of 500mm×115mm×15mm, the others are the same as in Embodiment 1.

[0041] Finally, the position of the crack-type defect in the alloy steel metal material to be detected was detected with a positioning error of 1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com