Front end buck convertor lossless buffer circuit for controlling superpower high-speed motor

A snubber circuit and high-power technology, which is applied in the field of motor control and non-destructive snubber circuit, can solve the problems of long reverse recovery time, large switching loss, high switching frequency, etc., and achieve the effect of reducing the total volume, reducing loss, and facilitating capacity expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

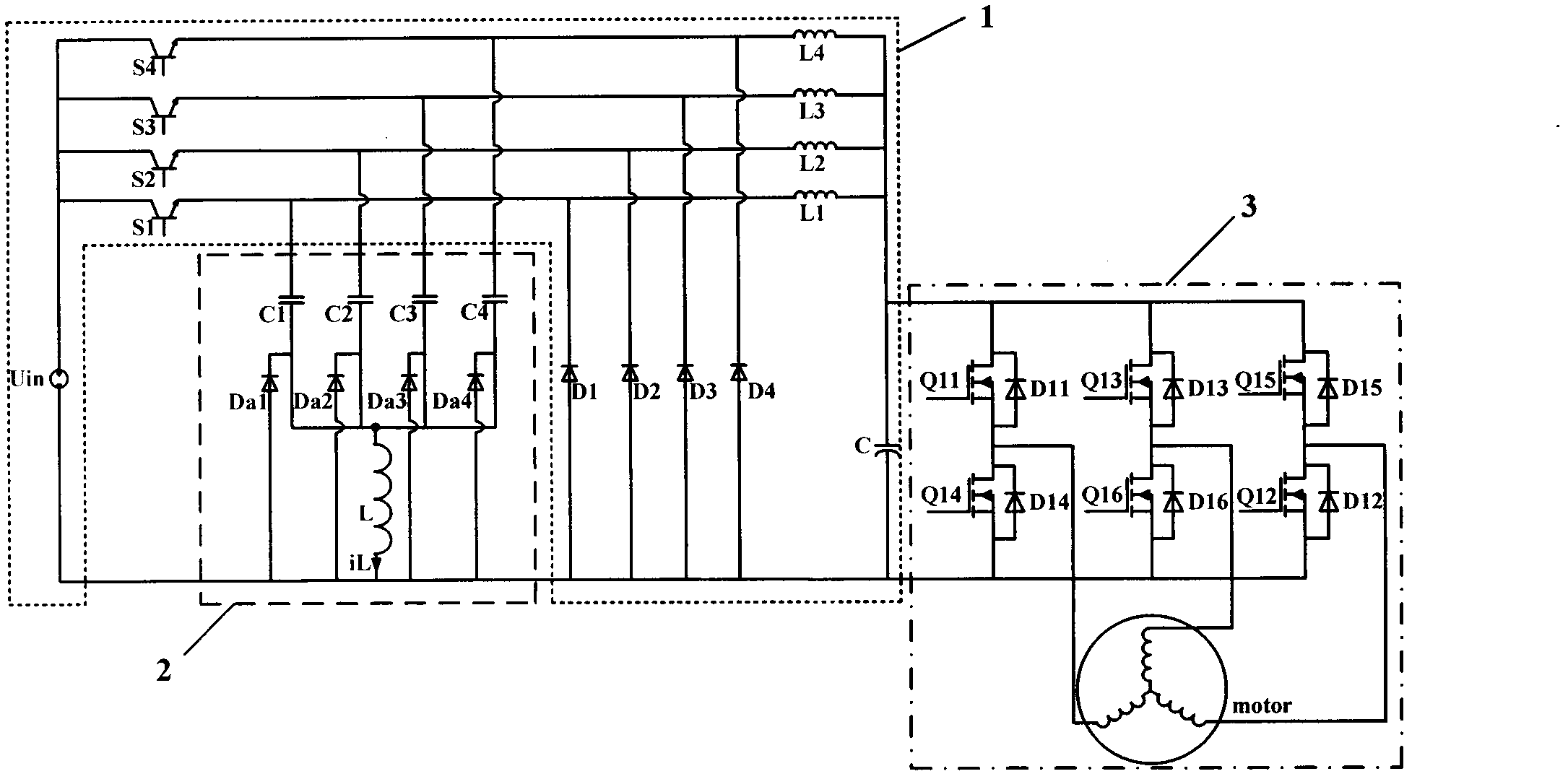

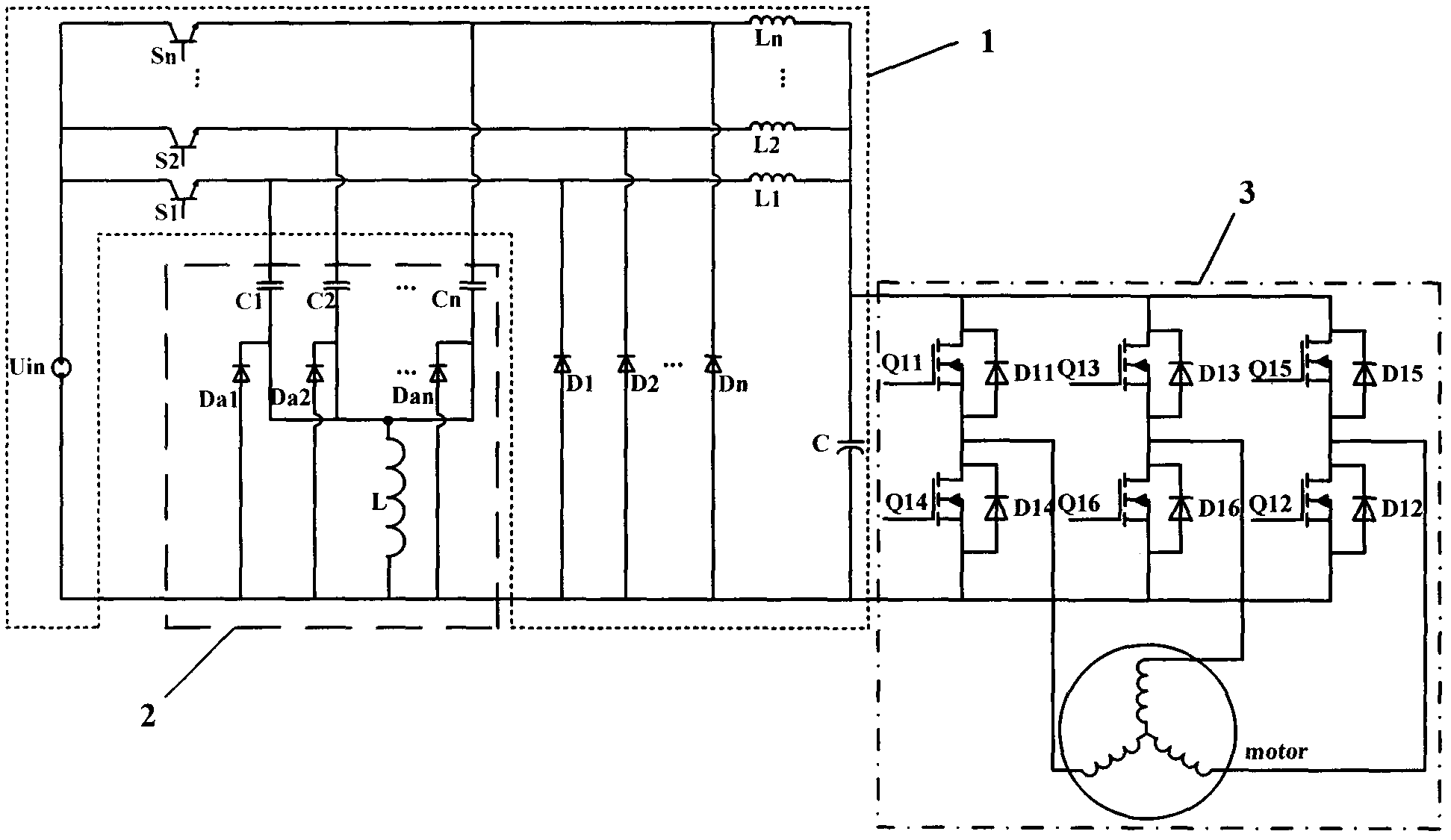

[0013] The circuit topology of this patent is as figure 1 As shown, on the basis of the traditional high-speed motor control circuit, a Buck snubber circuit structure composed of inductance, capacitor and diode is added.

[0014] The main circuit topology is as figure 1 shown. The main body consists of DC input, power switch tube, capacitor and inductor, diode, output capacitor, three-phase inverter bridge, and motor. Its connection method is: power switch S 1 , S 2 , S 3 , S 4 The drain of the input DC power supply U in Connected to the positive input terminal, the gate input is a high-frequency modulation signal, and the source is connected to the inductor L 1 , L 2 , L 3 , L 4 The positive end is connected. Snubber circuit capacitance C 1 、C 2 、C 3 、C 4 respectively connected to the power switch S 1 , S 2 , S 3 , S 4 The source and snubber circuit diodes D a1 、D a2 、D a3 、D a4 between the cathodes of the snubber circuit diode D a1 、D a2 、D a3 、D a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com