Brake system having a multifunction memory device

A brake system and functional technology, applied in the direction of brakes, brake transmission devices, foot-operated starting devices, etc., to achieve the effect of fully self-adaptive idle stroke adjustment and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

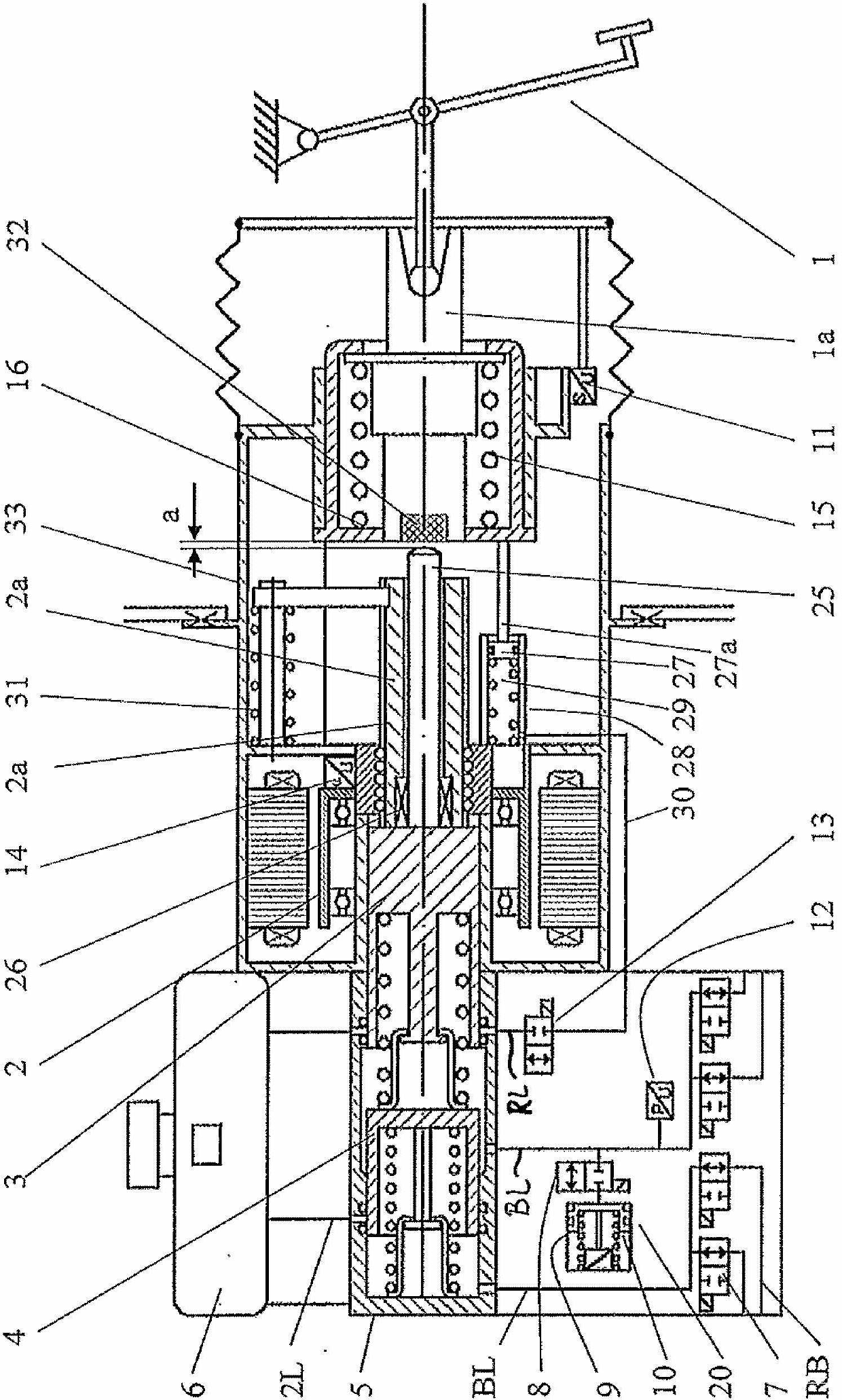

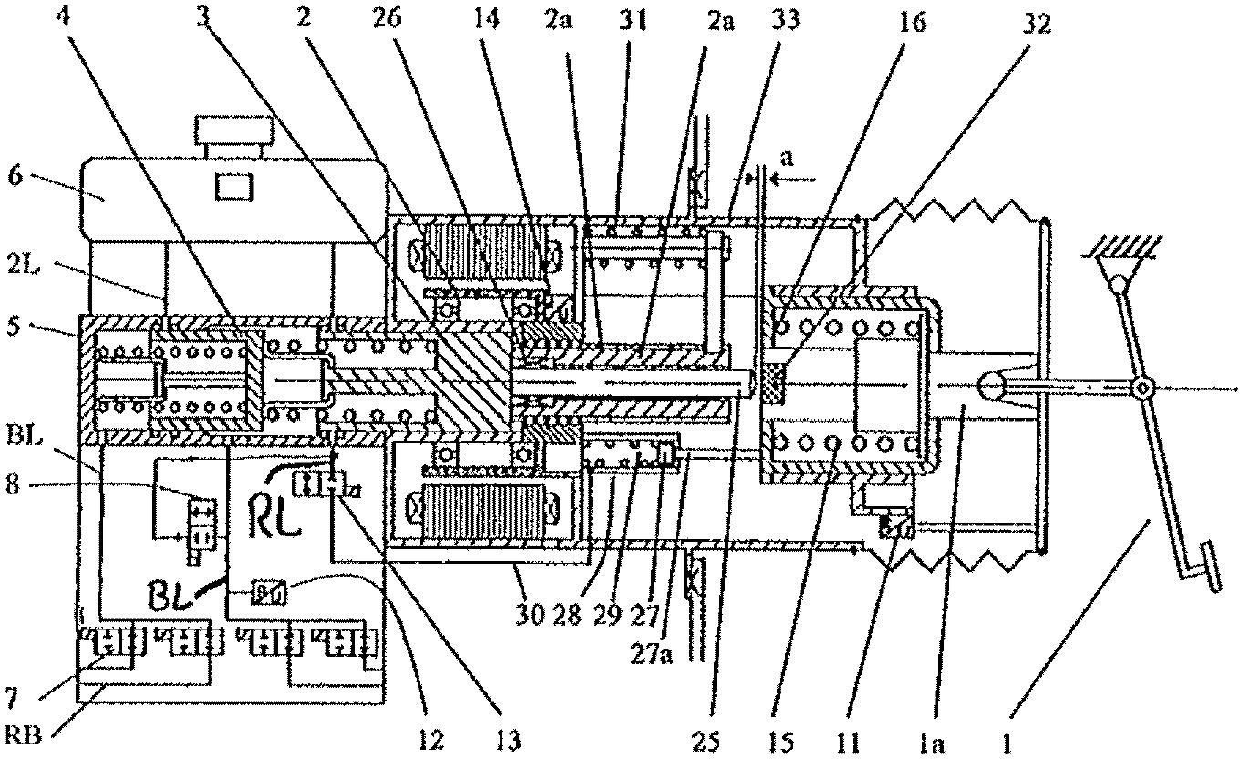

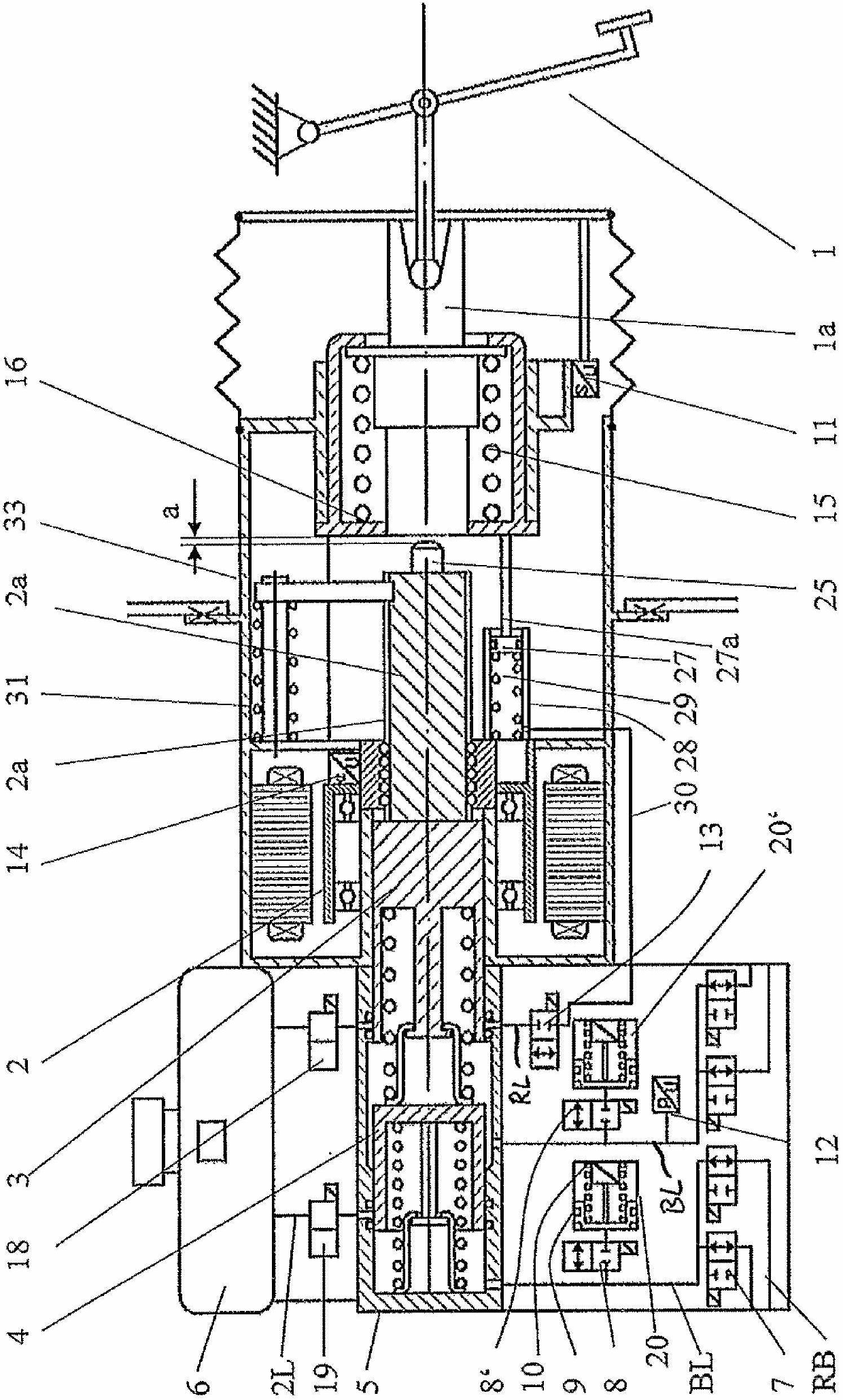

[0037] figure 1 The basic configuration of a highly dynamic motor drive 2 is shown, which moves a piston 3 to vary the pressure in the wheel brakes RB, wherein a wheel brake valve 7 is assigned to each wheel brake RB so that the The brake pressure can be adjusted sequentially, that is to say in multiplex operation. Furthermore, the drive 2 adjusts the piston 3 for the ABS / ESP function. On the electric motor 2 , a tappet piston 3 , which acts hydraulically on the floating piston 4 in a known manner in a tandem master cylinder 5 , is preferably fixedly coupled to the preferably spindle drive 2 a. A 2 / 2 wheel brake valve 7 is arranged in the brake line BL, which, together with the brake booster, realizes the multiplex operation described in WO 2006 / 111393. The brake pedal 1 acts via the pedal pushrod 1 a on a travel simulator spring 16 mounted in the WS housing 15 . This is preferably mounted axially centrally in the housing flange 33 .

[0038] The electric drive can obvious...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com