Sealed electronic housing and sealed assembly method for the housing

An assembly method and housing technology, applied in the direction of electric solid devices, circuits, electrical components, etc., can solve the problems of complex devices, long manufacturing time, etc., and achieve the effects of no equipment, easy implementation, and excellent mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

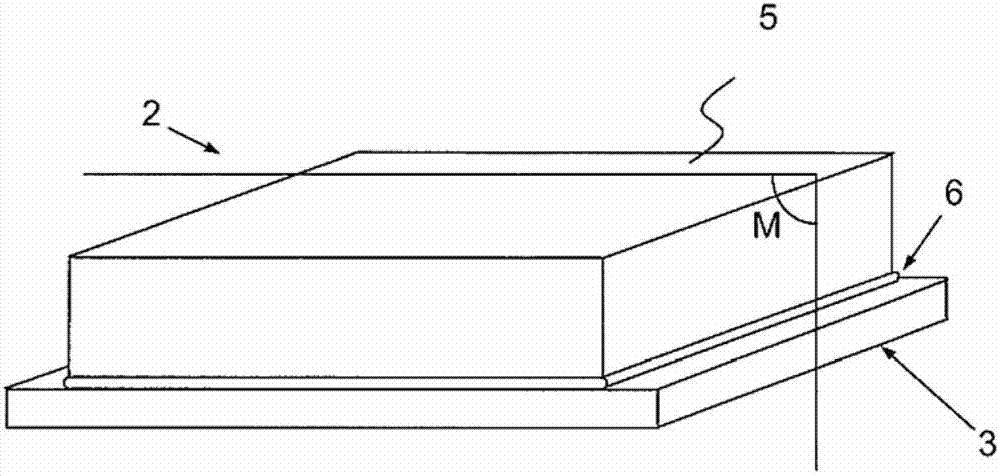

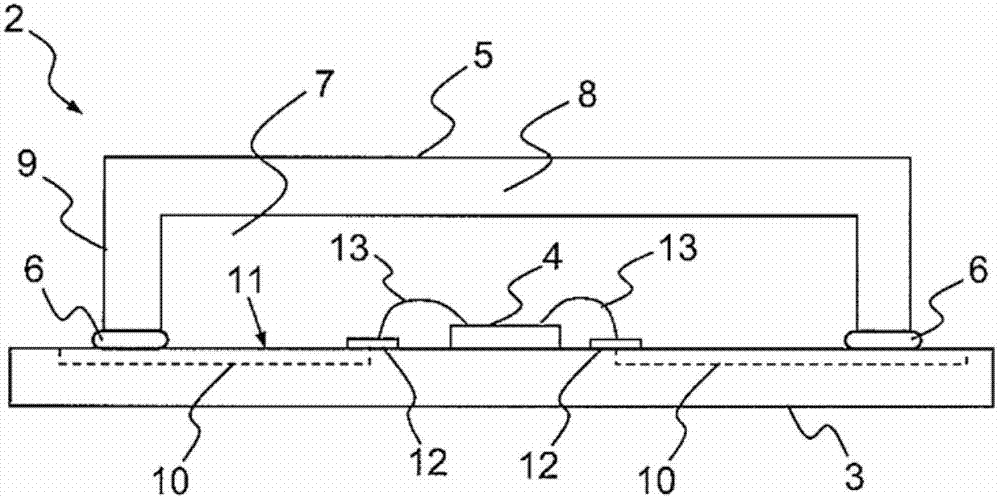

[0039] figure 1 The overall parallelepiped of the first example of the housing according to the invention is shown in perspective to seal the exterior of the electronics housing 2 . The sealed electronics housing 2 comprises a support 3 and a cover 5 arranged to form a cavity 7 for housing electronic components 4 (these components are shown in figure 2 Middle) defines the wall, the electronic component 4 is fixed to the support 3 . The support 3 and the cover 5 are connected in a sealed manner by means of a joint 6 comprising clusters of metal nanoparticles. The group has a mesoscopic structure.

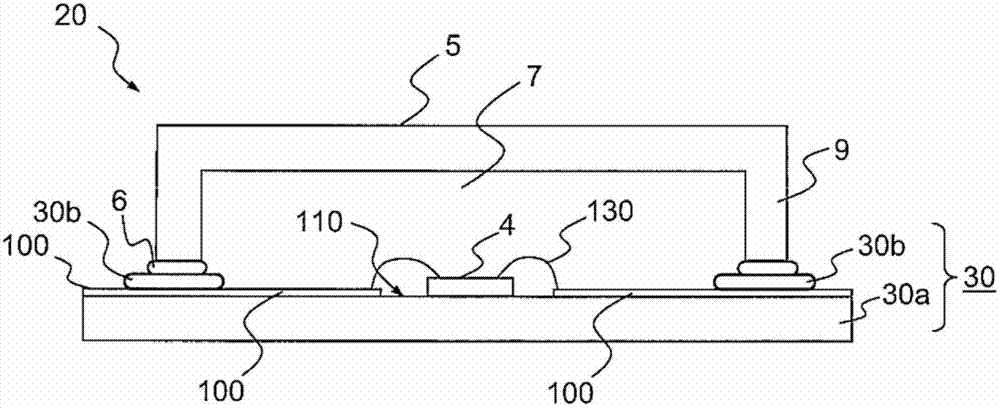

[0040] figure 2 schematically shows the figure 1 The cross-section of the shell in the vertical plane M. The electronics housing 2 comprises a cover 5 and a support 3 to which the electronic components 4 are fixed. exist figure 2 In the embodiment shown, the support 3 forms a base body which is generally flat-shaped. Furthermore, the support 3 has the function of a substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com