Rotor and vertical shaft type impact crusher provided with rotor

An impact crusher, vertical shaft technology, applied in the field of vertical shaft impact crushers, can solve problems such as increased production costs, wear of vertical rotor walls, expensive hard metals, etc., to reduce production costs of enterprises and prolong effective service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

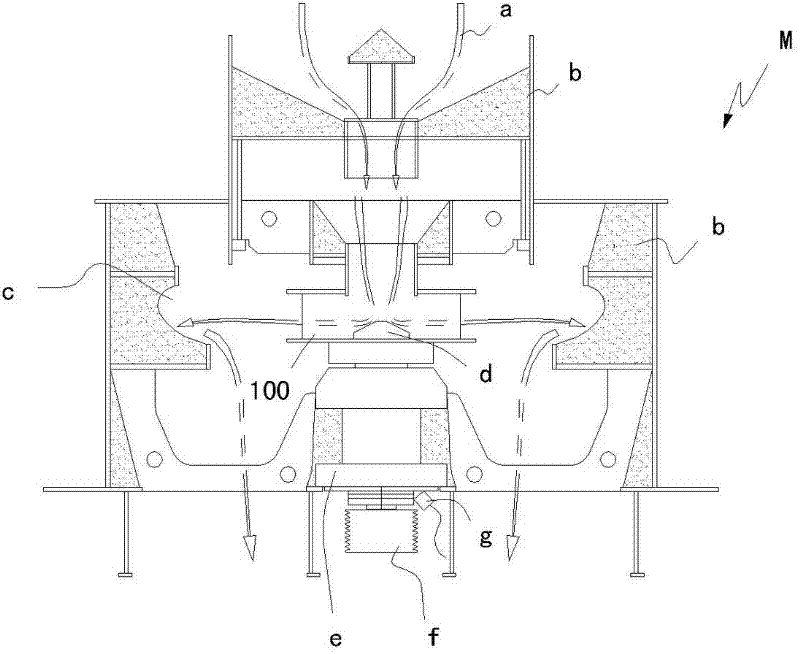

[0017] see figure 1 . figure 1 It shows a schematic longitudinal section structure diagram of a vertical shaft impact crusher M equipped with a rotor of the present invention. The material enters the rotor 100 from the material inlet in the center of the rotor 100 along the material flow direction a, driven by the vertical shaft installed on the vertical shaft bearing seat e, the distributor d and the rotor 100 rotate at high speed, so that the material can obtain enough crushing energy, And from the tangential direction of the parabolic head, that is, from the discharge port, it is separated from the rotor, flies out according to the predetermined trajectory, collides with the anvil of the crushing chamber c in a very short time, and realizes crushing by disintegrating itself and releasing energy. The vibration sensor g provides vibration signals for the on-board vibration detection device.

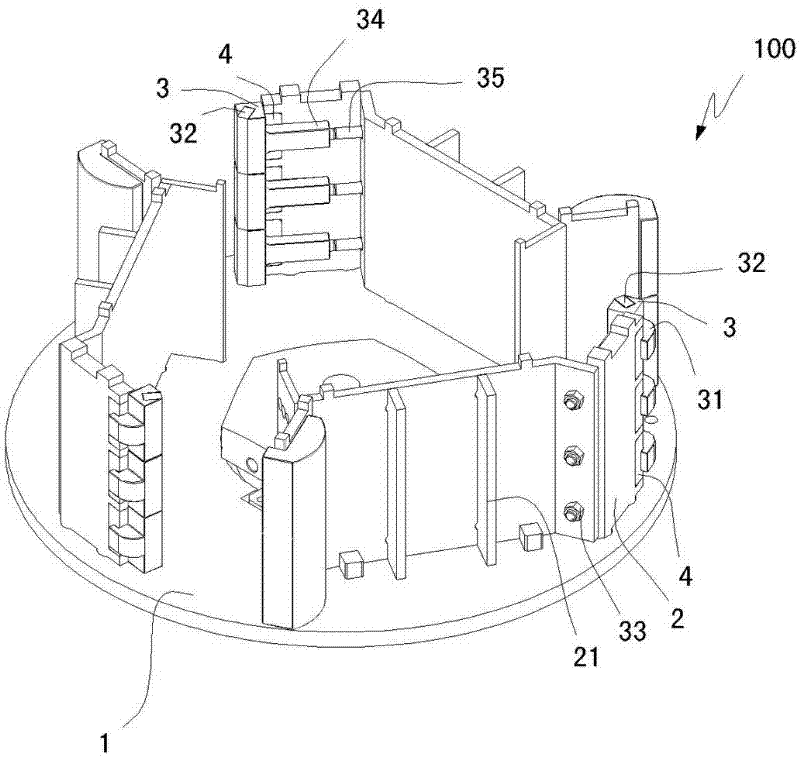

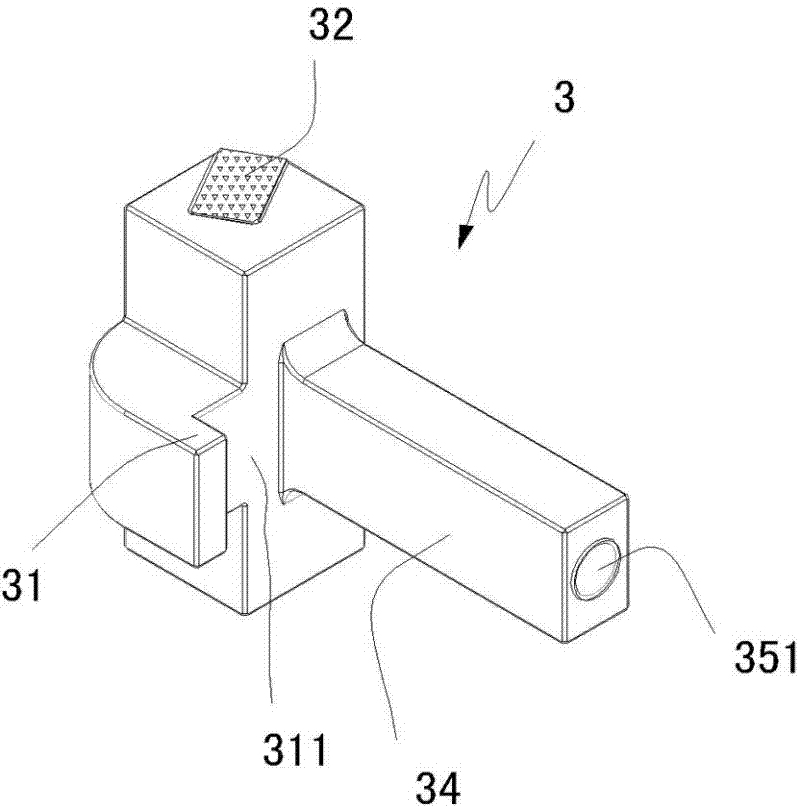

[0018] see figure 2 , and combined with image 3 , Figure 4 . This rotor inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com