Jade comb manufacturing method and jade comb manufacturing equipment

A production method and technology of jade combs, which are applied in stone processing equipment, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of poor processing accuracy, high defective product rate, rough comb, etc., and reduce defective products. Product rate, the effect of promoting blood circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

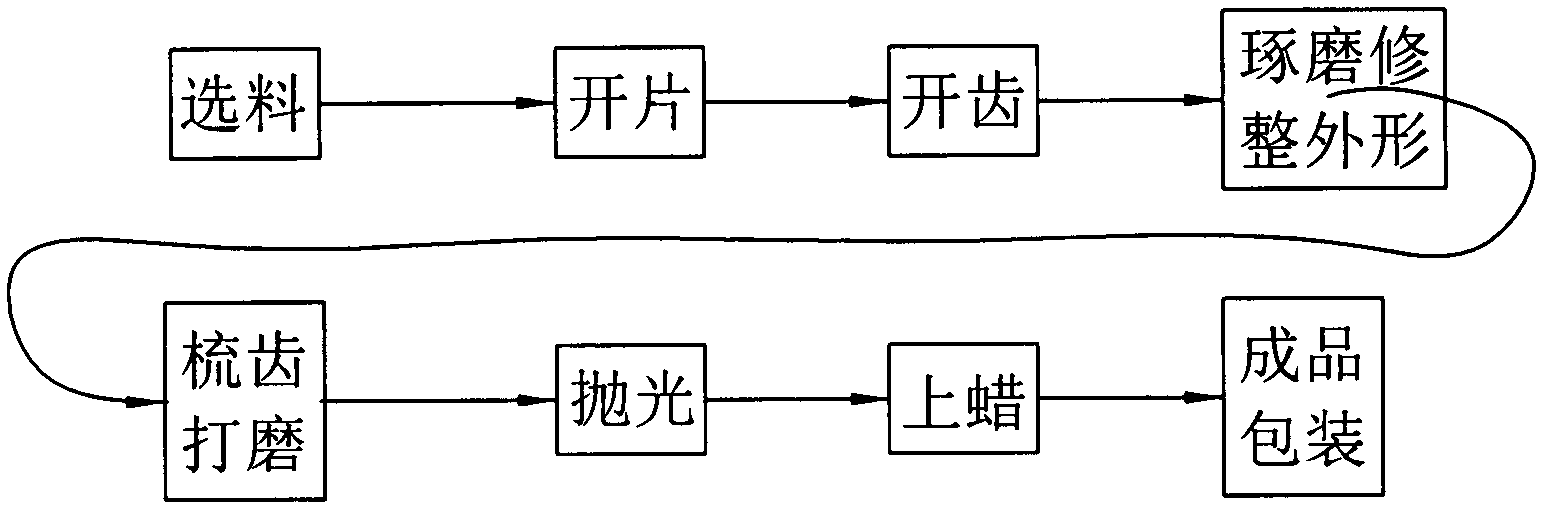

[0032] The invention provides a method for making a jade comb, comprising the following process steps:

[0033] a. Material selection: select raw materials, avoid cracked parts in the jade material, and design the cutting parts; Hetian jade, Xiu jade, Duyu, dark green jade and other natural jade materials can be selected as raw materials.

[0034] b. Slicing: Use a diamond sawing machine to decompose the jade material according to the designed cutting position to obtain a jade slice with a thickness of 90-100 mm in length, 42-45 mm in width and 5-7 mm in thickness; this size High-quality jade flakes make the jade combs made of them easier to hold, and at the same time, the jade flakes are not easy to be damaged or broken during the production process.

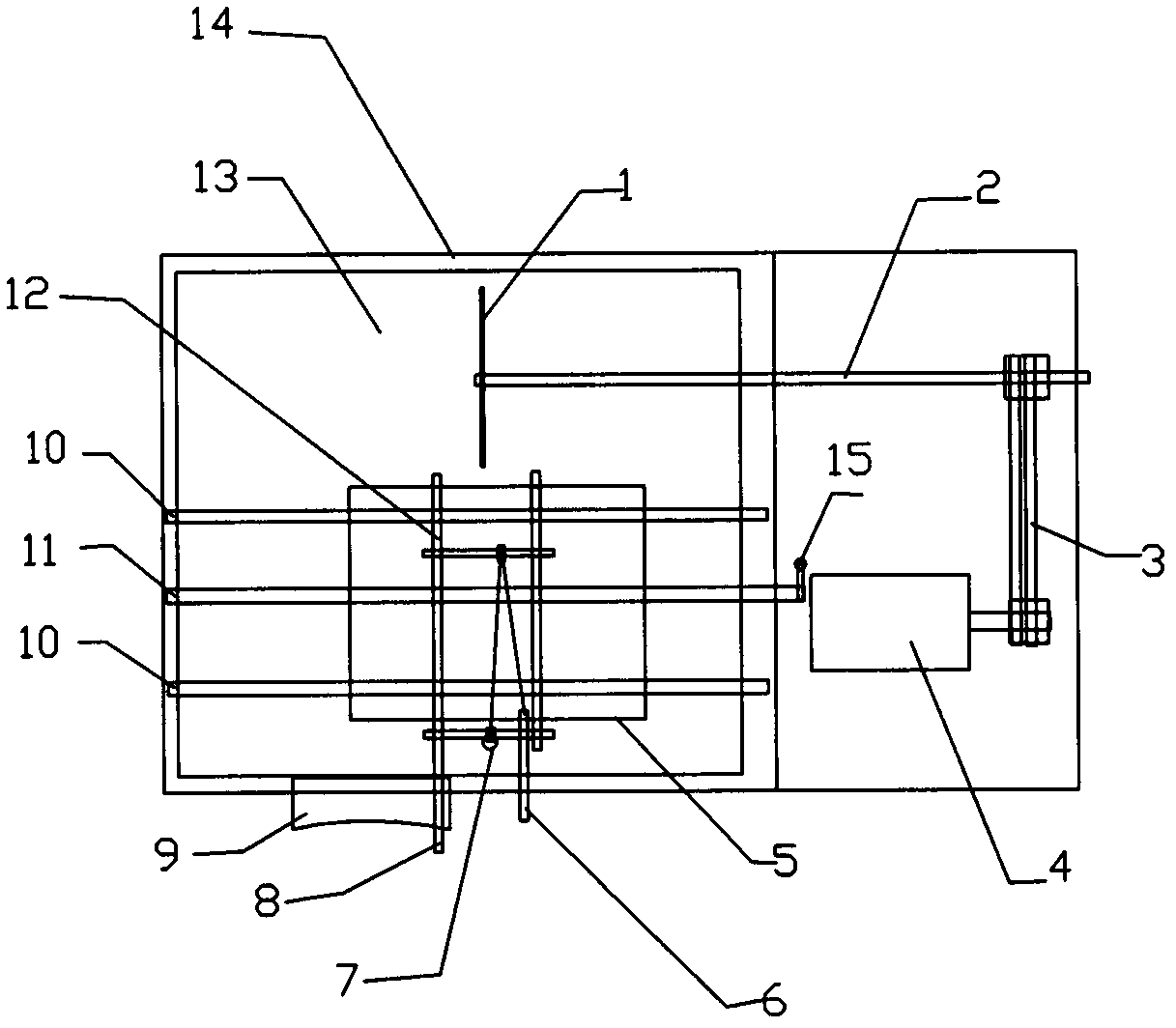

[0035] c. Teeth opening: Install the opened jade pieces on a sem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com