Gillyflower extract and preparation method and applications thereof

A technology of violet flower and extract, which is applied in the field of cigarette processing, and can solve the problems that the application of violet flower extract has not yet been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

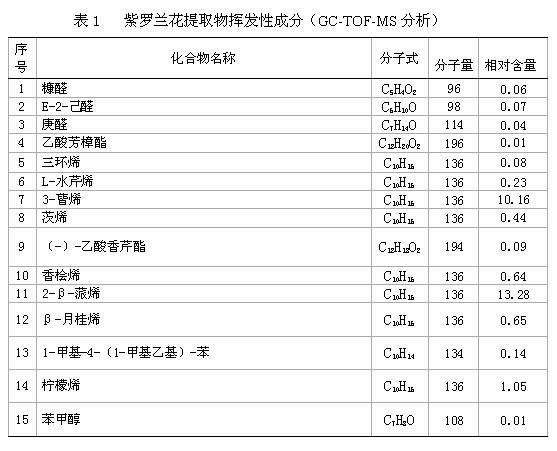

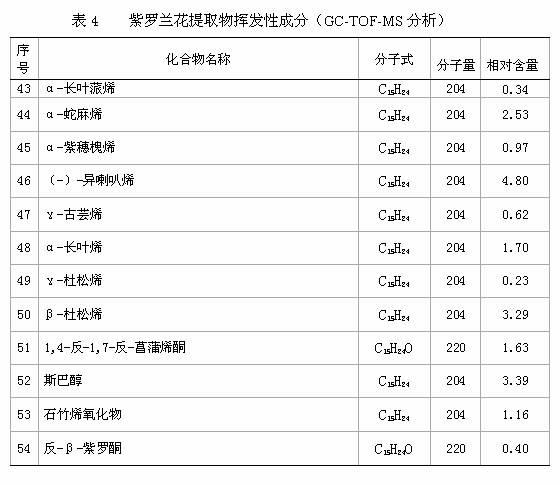

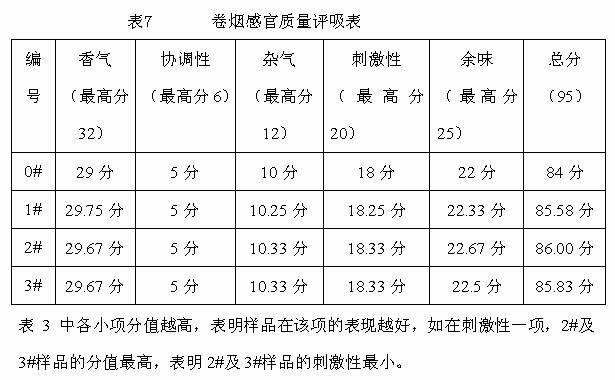

Examples

Embodiment 1

[0032] Preparation of violet flower extract: (1) Dry fresh violet flowers in the shade until the water content of violet flowers is 15% by mass fraction, and then crush them through a 20-mesh sieve to obtain violet flower powder; The place that doesn't see the sun dries slowly.

[0033] (2) Simultaneously distill and extract the violet flower powder described in step (1) using a simultaneous distillation extractor, weigh 50 g of the violet flower powder described in step (1), and place it in a round-bottomed flask in the simultaneous distillation extractor Add 500ml of distilled water, and heat it with a voltage-controllable electric heating mantle. The control voltage is 200 V, and the temperature is 100-110°C to keep the water boiling to generate steam; weigh 20 ml of dichloromethane and place it in another simultaneous distillation and extraction device. In a round bottom flask, heat it with a constant temperature water bath, extract continuously at 50°C for 1 hour, stop he...

Embodiment 2

[0042] Preparation of violet flower extract: In addition to step (1) drying fresh violet flowers in the shade until the water content of violet flowers is 17% by mass fraction, step (2) adding 1000ml of distilled water to a round-bottomed flask filled with violet flower powder, containing two The round-bottomed flask of methyl chloride was continuously extracted at 50° C. for 3 hours, and the rest of the steps were the same as in Example 1 and were not repeated.

[0043] The application of violet flower extract: same as embodiment 1, effect is the same as embodiment 1.

Embodiment 3

[0045] Preparation of Violet Flower Extract: In addition to step (1) drying fresh Violet Flowers in the shade until the water content of Violet Flowers is 20% by mass fraction, step (2) add 1500ml of distilled water to a round-bottomed flask filled with Violet Flower powder, containing two The round bottom flask of methyl chloride was continuously extracted at 50° C. for 5 hours, and the rest of the steps were the same as those in Example 1, and will not be repeated.

[0046] The application of violet flower extract: same as embodiment 1, effect is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com