Carbon-containing polypropylene filament tow for cigarette and preparation method thereof

A technique for polypropylene and polypropylene slicing, which is applied in the manufacture of single-component polypropylene rayon, single-component polyolefin rayon, and rayon, and can solve the problems of uneven distribution of activated carbon, difficulty in processing, and easy carbon particles. Pollution and other problems, to achieve the effect of not affecting the filter rod index, easy to control the amount of application, and good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

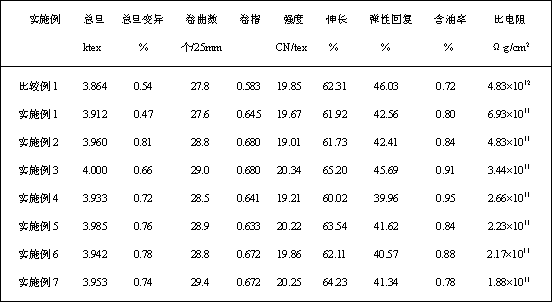

Examples

Embodiment 1

[0031] 2.5% cooling masterbatch of auxiliary materials, 4.0% modified masterbatch, 5% functional masterbatch (effective carbon content in functional masterbatch is 20%, activated carbon particle size 0.3~1.0μm, activated carbon pore size 0.5~0.8nm, activated carbon specific surface area 600~1000m 2 / g) After drying, mix well. The melt index of the cooling masterbatch is 30-45g / 10min; the melt index of the modified masterbatch is 15-30g / 10min.

[0032] The feeding speed of the auxiliary material and the main material (the remaining polypropylene chips, wherein the melt index of the polypropylene chips is 20~30g / 10min) is controlled by a metering pump, and the speed ratio of the metering pump is controlled at 0.106±0.005. Out of the machine for melt spinning, the number of holes in the spinneret is 11000 holes, and the screw temperature is set as: 240±5℃ in the first zone, 255±5℃ in the second zone, 270±5℃ in the third zone, 270±5℃ in the fourth zone , the fifth zone is 270±5°...

Embodiment 2

[0037] 2.0% cooling masterbatch of auxiliary materials, 3.0% of modified masterbatch, 10% of functional masterbatch, fully mixed evenly after drying, control the feeding speed of auxiliary materials and main materials (residual polypropylene slices) through metering pump, metering pump The speed ratio is controlled at 0.106±0.005, melted and spun by the screw extruder, the number of holes in the spinneret is 11,000 holes, and the screw temperature is set as: 240±5℃ in the first zone, 255±5℃ in the second zone, and 255±5℃ in the third zone. 270±5℃, 270±5℃ in the fourth zone, 270±5℃ in the fifth zone, 270±5℃ in the sixth zone, 270±5℃ in the seventh zone, the pressure after the melt filtration is controlled at 8.5±0.5MPa, and the filter temperature is set to : Zone 1 265±5℃, zone 2 265±5℃, pipeline temperature: 265±5℃, box temperature: 265±5℃, box biphenyl pressure: <0.15MPa, ring air temperature: 22±3℃ , Spinning chamber ambient temperature: 15~35°C, tanker speed: 14.5±0.5m / min,...

Embodiment 3

[0043] 2.0% cooling masterbatch of auxiliary materials, 2.5% of modified masterbatch, 15% of functional masterbatch are fully mixed after drying, and the feeding speed of auxiliary materials and main materials (residual polypropylene slices) is controlled by metering pump, and the speed of metering pump is The ratio is controlled to be 0.106±0.005, melt spinning through the screw extruder, the number of holes in the spinneret is 11000 holes, the screw temperature is set as: 240±5°C in the first zone, 255±5°C in the second zone, 270 in the third zone ±5°C, 270±5°C in the fourth zone, 270±5°C in the fifth zone, 270±5°C in the sixth zone, 270±5°C in the seventh zone, the pressure after the melt filtration is controlled at 8.5±0.5MPa, and the filter temperature is set as: Zone 1: 265±5°C, Zone 2: 265±5°C, pipeline temperature: 265±5°C, box temperature: 265±5°C, box biphenyl pressure: <0.15MPa, ring air temperature: 22±3°C, Spinning chamber ambient temperature: 15~25°C, tanker spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com