Four-roller oversized drafting compact spinning device

A technology of ultra-large draft and compact spinning, which is applied in drafting equipment, spinning machines, textiles and papermaking, etc., to achieve the effects of reducing energy consumption, improving drafting effect, and increasing drafting ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

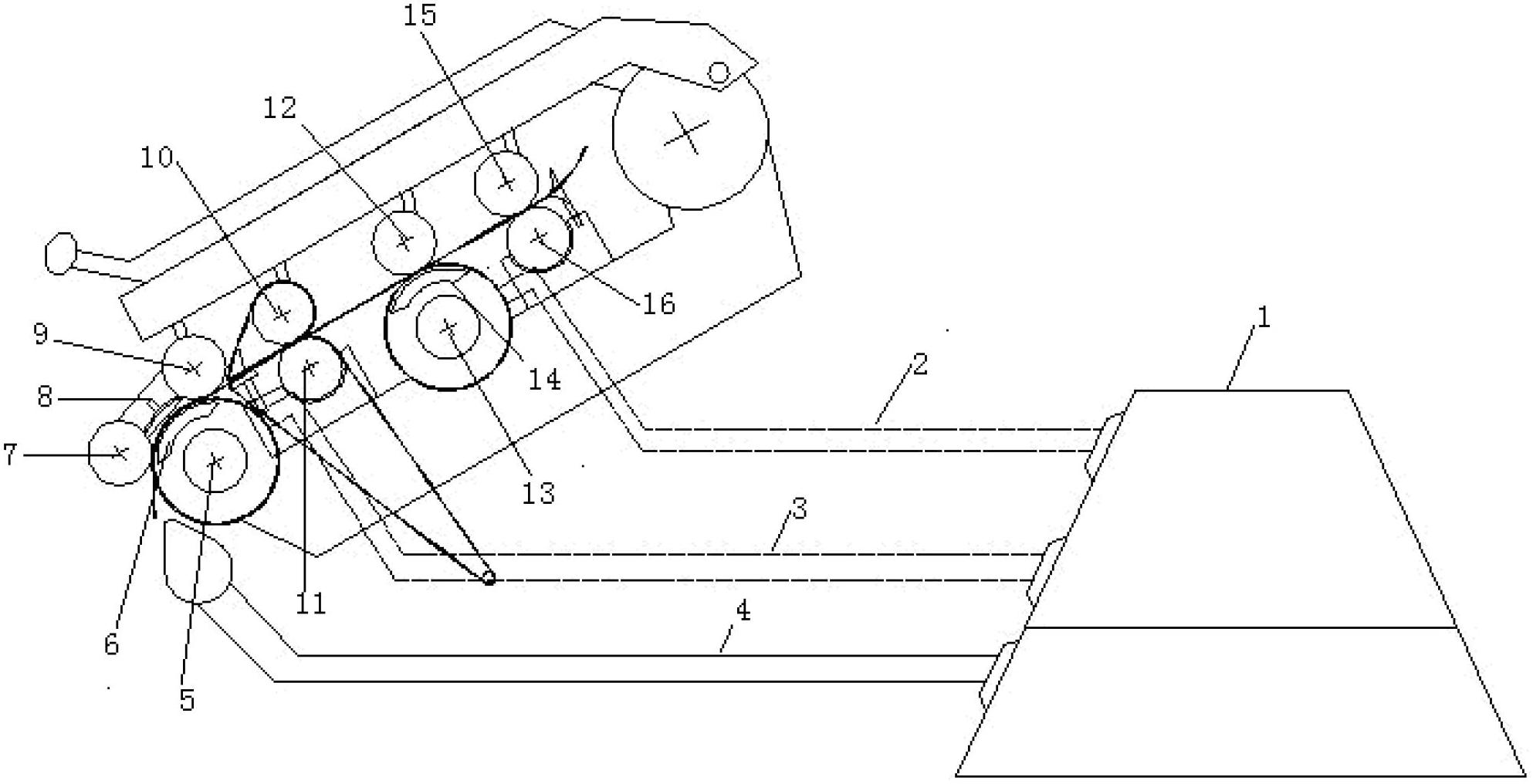

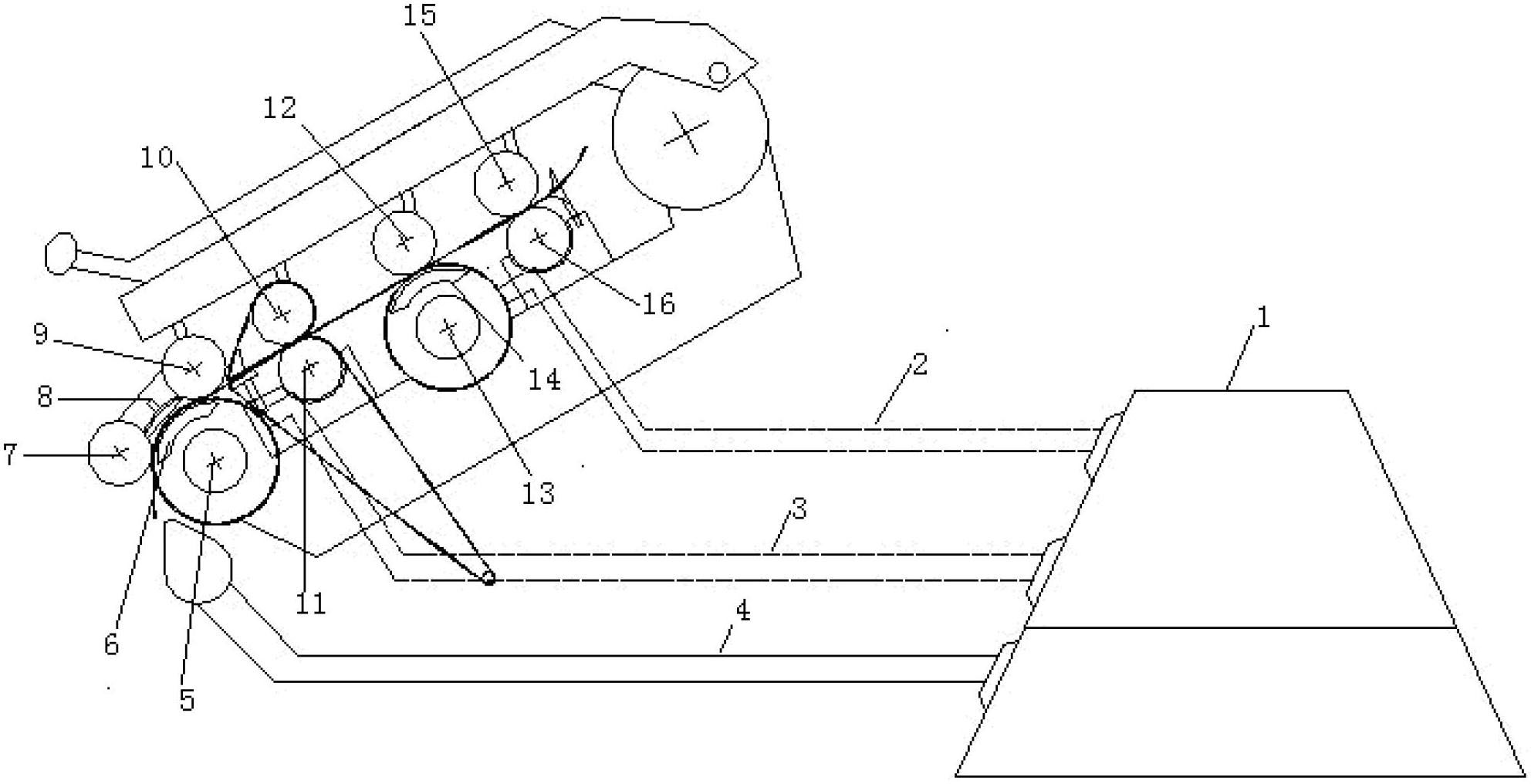

[0014] Such as figure 1 In the structure of the four-roller ultra-large draft compact spinning device shown, the rear roller 16 and the rear top roller 15 form the rear drafting roller pair; The drafting roller pair, the narrow groove type negative pressure front bottom roller 5 is a steel hollow roller with a large diameter. The surface of the roller has narrow grooves arranged according to certain rules, and it automatically rotates at the speed specified by the drafting multiple, which looks like a small dust. The cage is equipped with a suction component 6 inside, and has concave-convex grooves on the surface, which can effectively improve the holding effect on the fibers and prevent the adhesion of the fibers. The hole sucks the airflow, so that the fibers in the gathering area are gathered, and the gathered strands are twisted after exiting the twist-resistance nip, and the drafting and twisting process is completed. In order to achieve the effect of "complete accumulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com