Intelligent electric heating drier

A technology of electric heating and drying machine, applied in the direction of drying machine, drying room/container, drying gas arrangement, etc., can solve the problems of large environmental pollution, low work efficiency, low degree of intelligence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

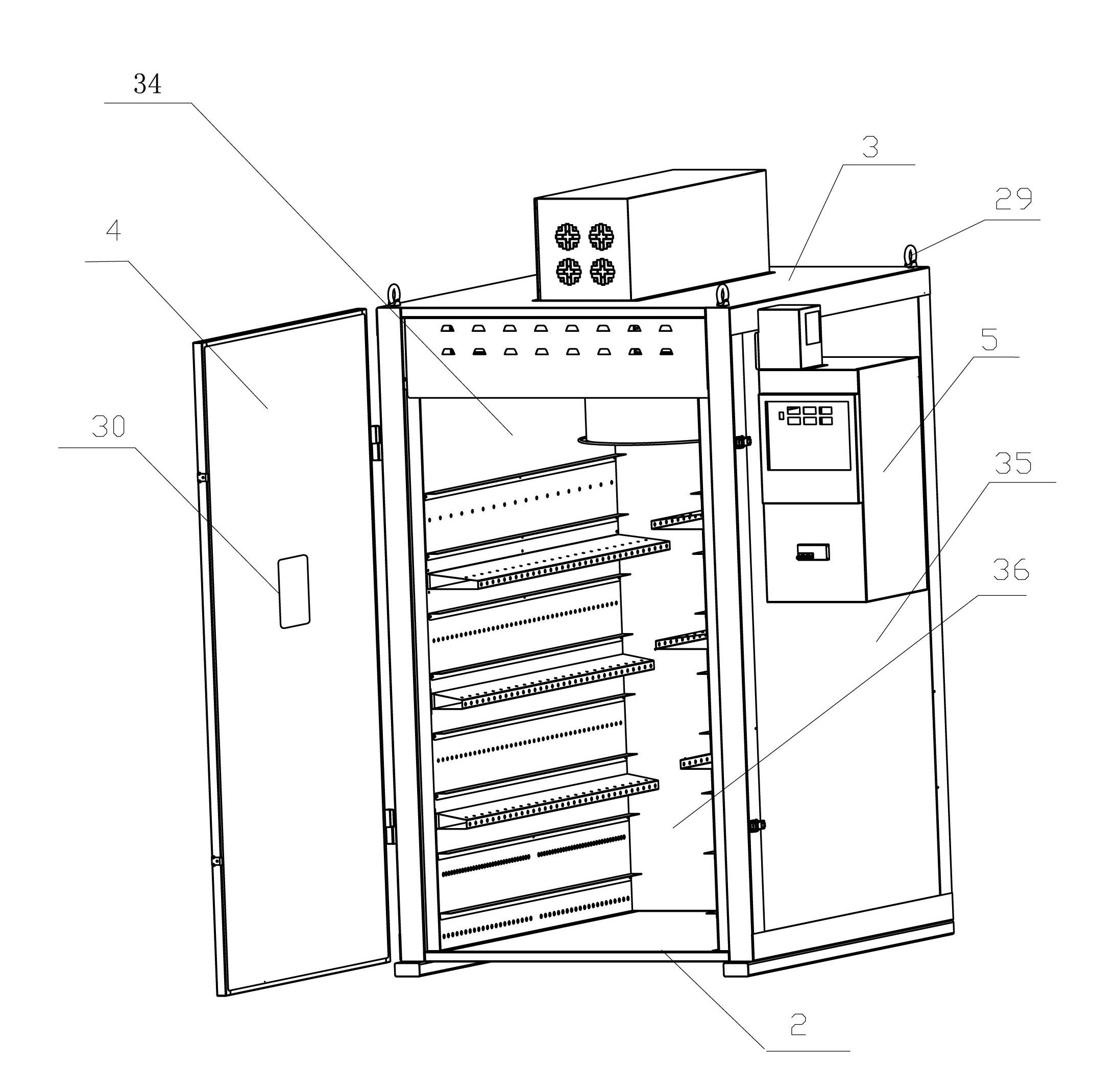

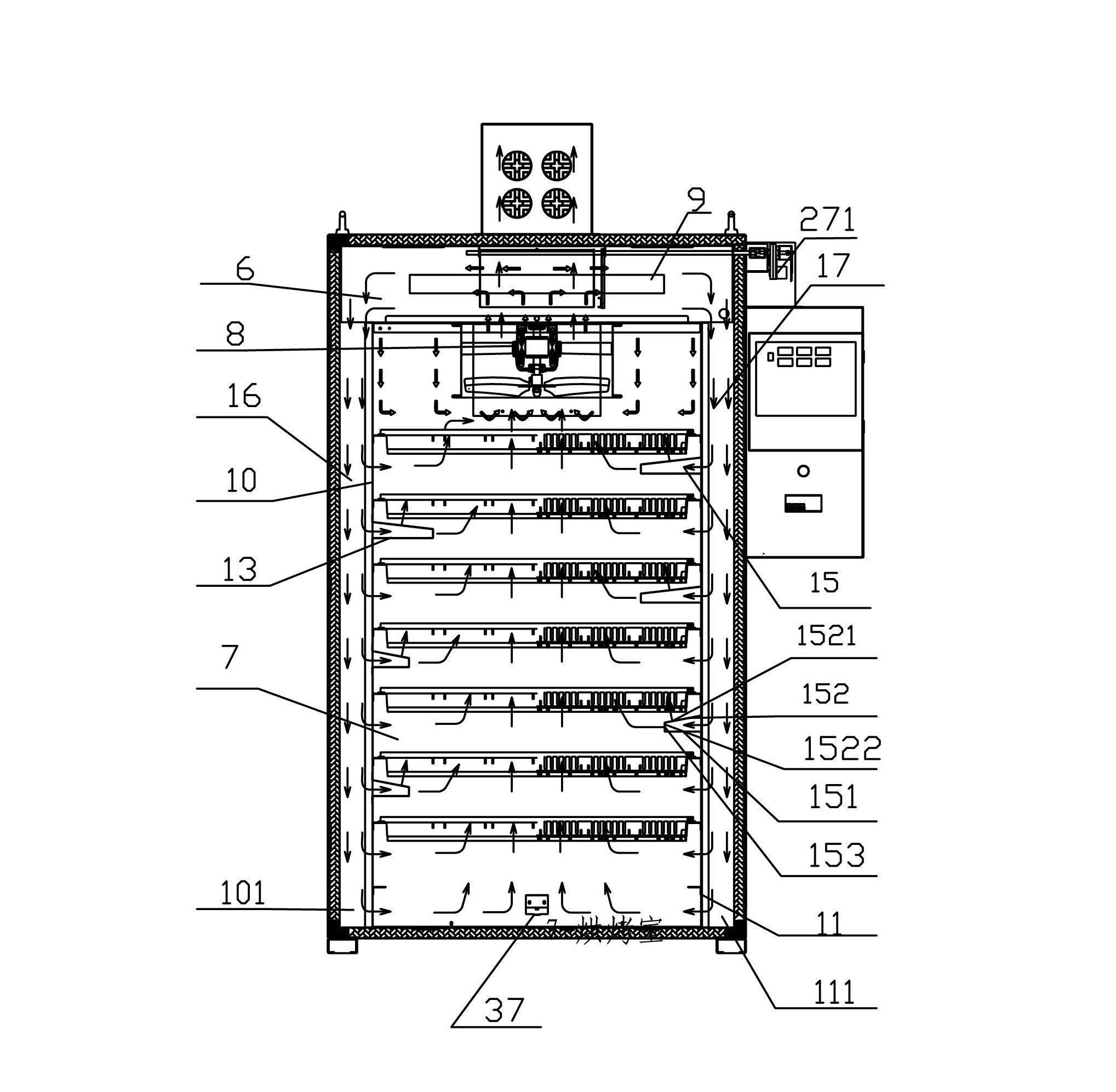

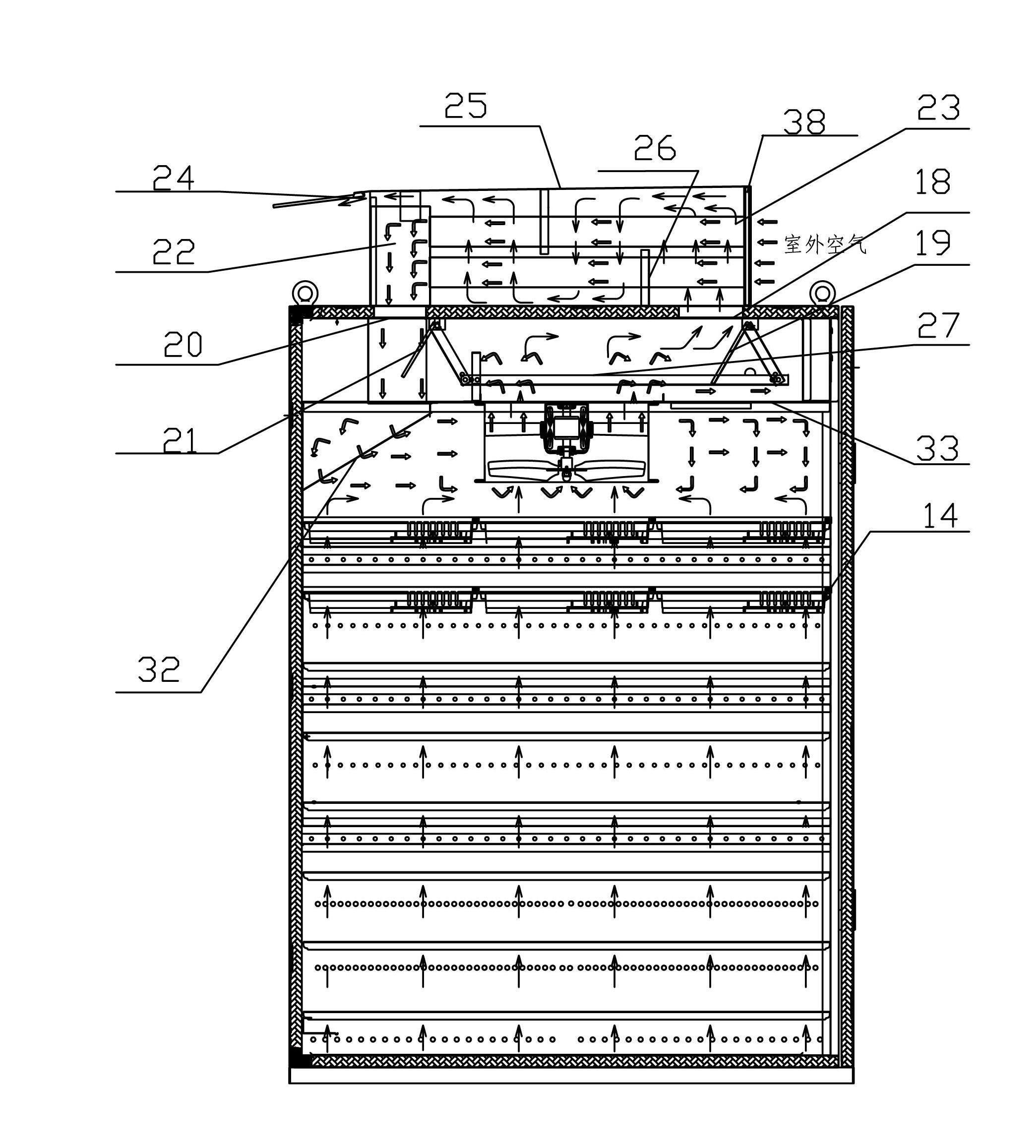

[0043] Such as figure 1 As shown, an intelligent electric heating dryer includes a left side panel, a right side panel, a back panel, a box bottom, a box top and a box door, a left side panel, a right side panel, a back panel, a box bottom, a box top and a box door enclosure There is an electric control box outside the working chamber, a heating chamber, a drying chamber, a circulation fan and a heater are arranged in the working chamber, the heating chamber and the drying chamber are separated by a partition, and the circulation fan is fixed on the partition , the air inlet of the circulation fan is located in the drying chamber, the air outlet of the circulation fan is located in the heating chamber, and the heater is arranged in the heating chamber,

[0044] The left side panel, the right side panel, the back panel, the bottom of the box and the top of the box all include an inner wall, an outer wall and an insulation layer arranged between the inner wall and the outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com