Improved evaporative cooling tower

An evaporative cooling and cooling tower technology, applied in the field of cooling towers, can solve the problems of prolonged falling time of water, collapse and air contact, etc., and achieve the effects of convenient production and life, low use cost and good cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

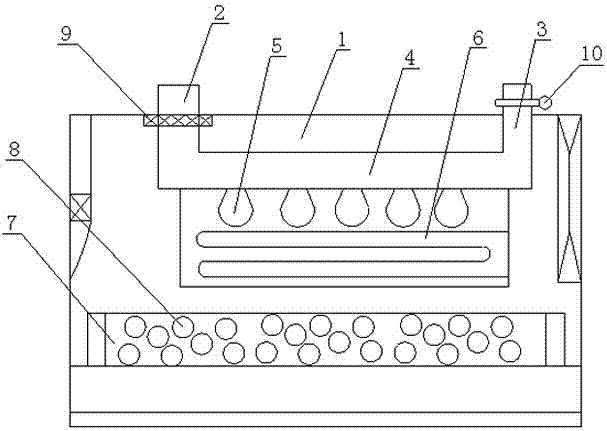

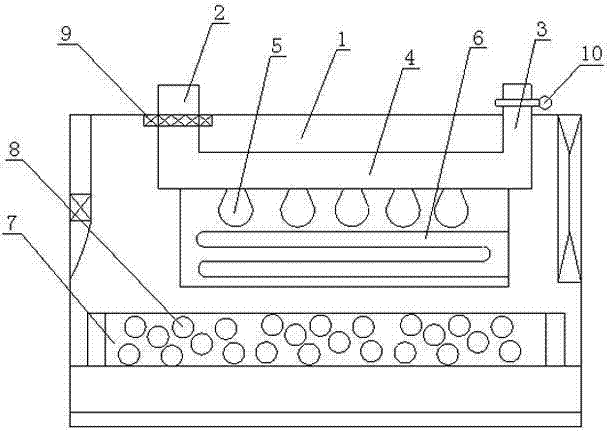

[0013] Such as figure 1 As shown, an improved evaporative cooling tower of the present invention includes a cooling tower body 1, a water inlet 2 is provided on one side of the top of the cooling tower body 1, a water outlet 3 is provided on the other side of the top of the cooling tower body 1, and a water inlet 2 It is connected with the water outlet 3 through the pipe 4, and the pipe 4 is provided with a spray water distribution system. The spray water distribution system includes a plurality of nozzles 5 and an evaporation coil 6, and the plurality of nozzles 5 are evenly distributed in the horizontal direction. The pipe 6 is located below the nozzle 5, and the lower part of the spray water distribution system is equipped with a water collecting device, which includes a water collecting tank 7 and a floating ball 8, the floating ball 8 is set inside the water collecting tank 7, and the water inlet 2 is also equipped with Stainless steel filter screen 9, water outlet 3 plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com