Back electrode structure of back contact silicon solar cell panel and manufacture method thereof

A technology of silicon solar cells and back electrodes, applied in the field of solar cells, can solve the problems of high cost, cumbersome operation, and high price of conductive adhesive, and achieve the effects of low cost, simple preparation method, increased reliability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

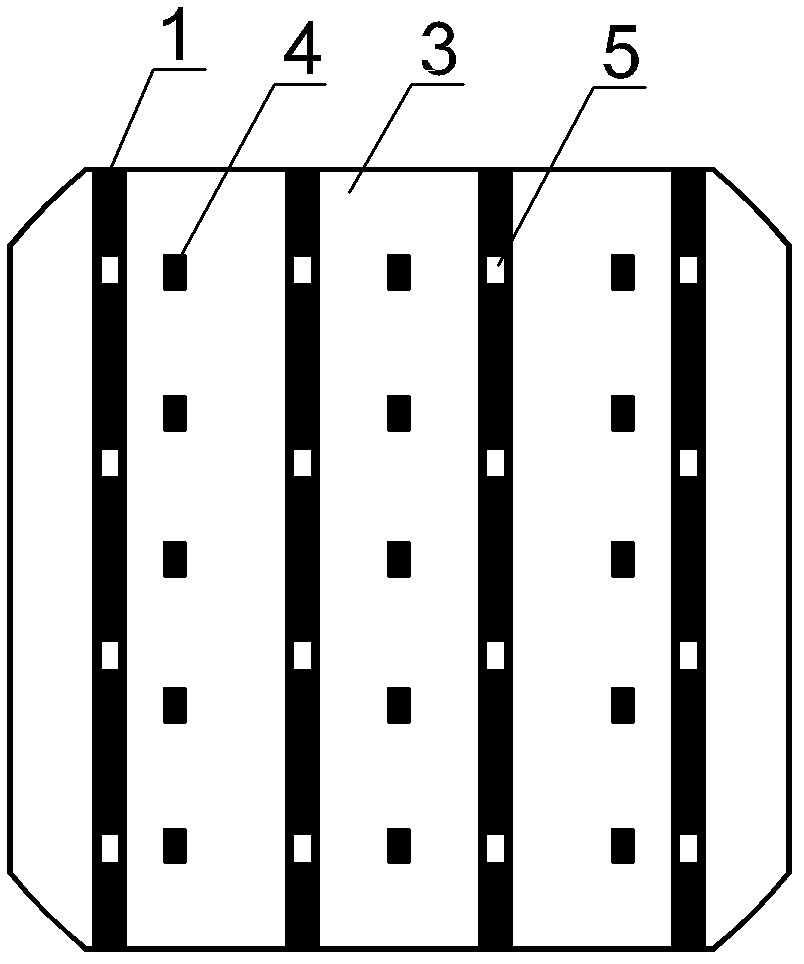

[0041] see figure 1 , 4 , shown in 5, a back electrode structure of a back contact silicon solar cell, the back side of the cell 3 is provided with a positive pole 4, a negative pole 5 and a back electric field; the polarity of the positive pole and the back electric field is the same; the negative pole Arranged side by side to form 4 negative electrode columns; the surface of each negative electrode column is covered with a strip-shaped insulating film layer 1, the number of insulating film layers is the same as the number of negative electrode columns, and the insulating film layer Extending along its length to both ends of the battery sheet;

[0042] Electrode windows are opened on the insulating adhesive film layer relative to the positions of the negative electrodes.

[0043] The insulating film layer has a thickness of 25-30 microns and a width of 5 mm. The insulating adhesive film layer is a polyester insulating adhesive film layer. The electrode window is rectangul...

Embodiment 2

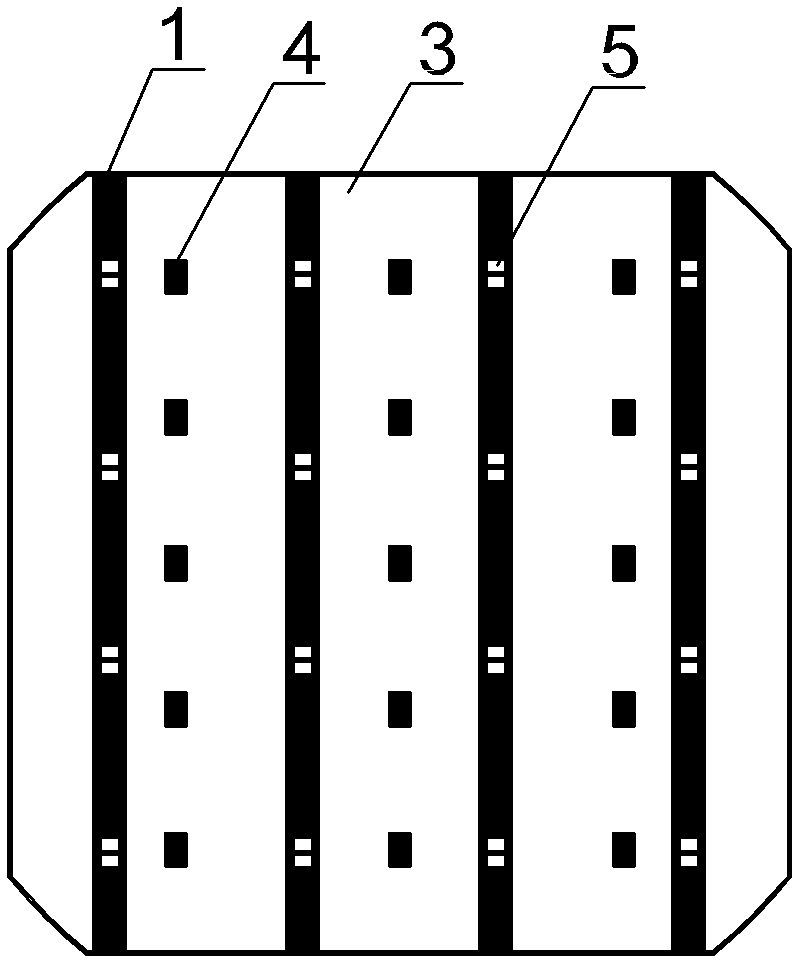

[0050] see figure 2 As shown, a back electrode structure of a back contact silicon solar cell, the back of the cell 3 is provided with a positive pole 4, a negative pole 5 and a back electric field; the polarity of the positive pole and the back electric field is the same; the negative poles are arranged side by side , forming 4 rows of negative electrode columns; the surface of each negative electrode column is covered with a strip-shaped insulating film layer 1, the number of insulating film layers is the same as the number of negative electrode columns, and the insulating film layer is along its The length direction extends to both ends of the battery sheet;

[0051] Electrode windows are opened on the insulating adhesive film layer relative to the positions of the negative electrodes.

[0052] The insulating film layer has a thickness of 20 microns and a width of 6 mm. The insulating adhesive film layer is a polyester insulating adhesive film layer. The electrode windo...

Embodiment 3

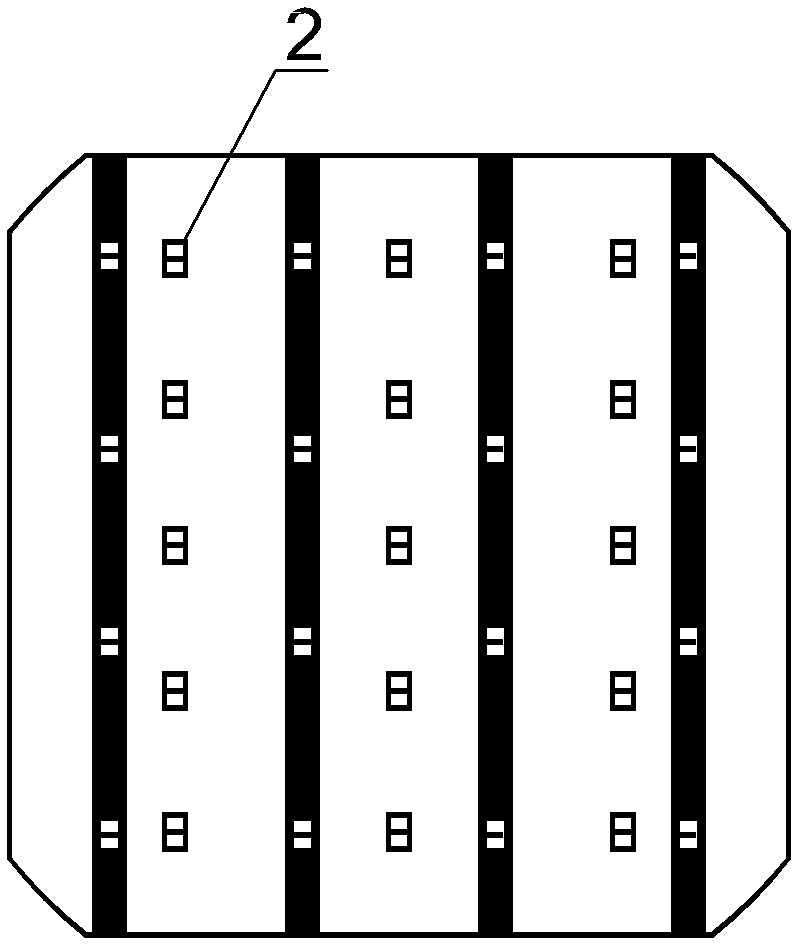

[0054] see image 3 As shown, a back electrode structure of a back contact silicon solar cell, the back of the cell is provided with a positive pole, a negative pole and a back electric field; the polarity of the positive pole and the back electric field is the same; the negative poles are arranged side by side to form 4 Negative electrode column; the surface of each negative electrode column is covered with a strip-shaped insulating adhesive film layer, the number of insulating adhesive film layers is the same as the number of negative electrode columns, and the insulating adhesive film layer extends along its length to Both ends of the cell;

[0055] Electrode windows are opened on the insulating adhesive film layer relative to the positions of the negative electrodes.

[0056] The thickness of the insulating adhesive film layer is 40 microns. The insulating adhesive film layer is a polyester insulating adhesive film layer. The electrode window is in the shape of a sun. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com