Low-vibration and low-noise small-and-medium-sized asynchronous motor

An asynchronous motor, low-noise technology, applied in the direction of asynchronous induction motors, electric components, electrical components, etc., can solve the problems of unconsidered vibration and noise reduction measures, increase in motor weight and size, low power density, etc., to avoid heat transfer loss, improved heat dissipation efficiency, and reduced aerodynamic noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

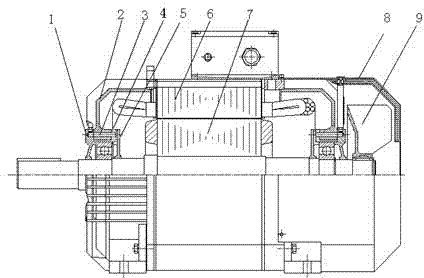

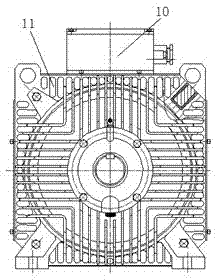

[0023] Such as figure 1 , as shown in 2, the low-vibration and low-noise small and medium-sized asynchronous motor of the present invention includes bearing outer cover 1, composite damping end cover 2, damping pad 3, bearing 4, bearing inner cover 5, stator 6, rotor 7, sound-absorbing Wind cover 8, fan 9, junction box 10 and end cover 11 etc.

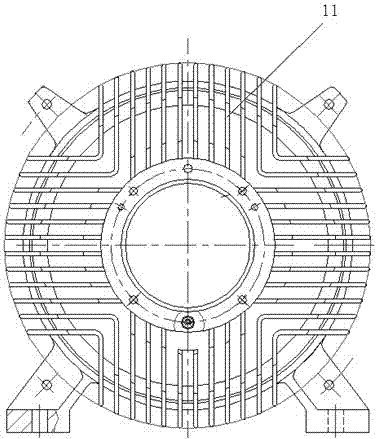

[0024] The end cover 11 is fixedly connected with a composite damping sleeve 12 to form a composite damping end cover 2, which is used to suppress the vibration of the transmission path of the rotor, bearing, end cover, machine base, and mounting machine feet; the stator 6 is composed of an integrated shell iron core and embedded The stator winding installed on the iron core is composed of; the integrated shell iron core includes a pressure ring 14, a damping piece 15, an iron core 16, an end plate 17, a bracket 18, and a da...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap