High-voltage side gate driving circuit capable of resisting common-mode noise interference

A gate drive circuit and common-mode noise technology, applied in the field of common-mode noise elimination circuit design, to achieve the effects of reliable filtering of common-mode noise, small overall delay, and small transmission delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

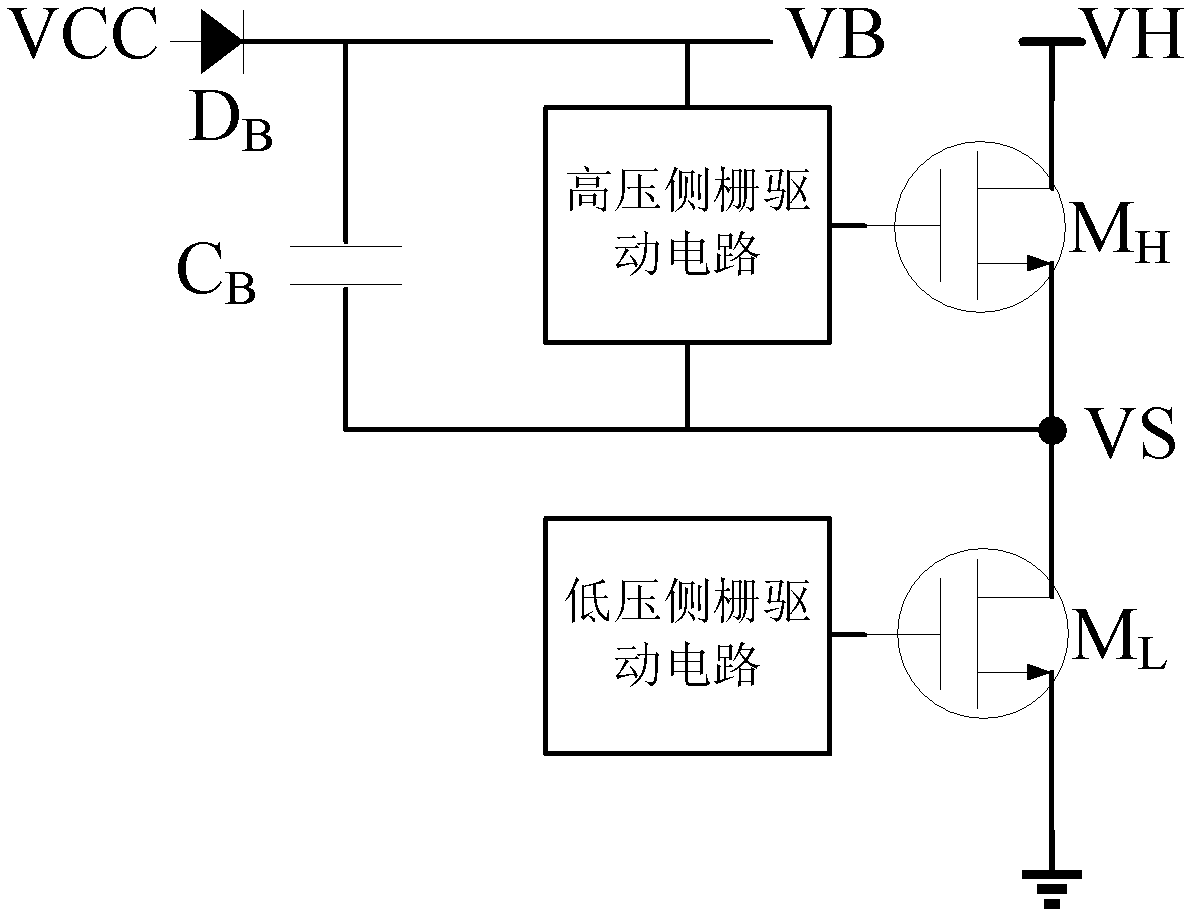

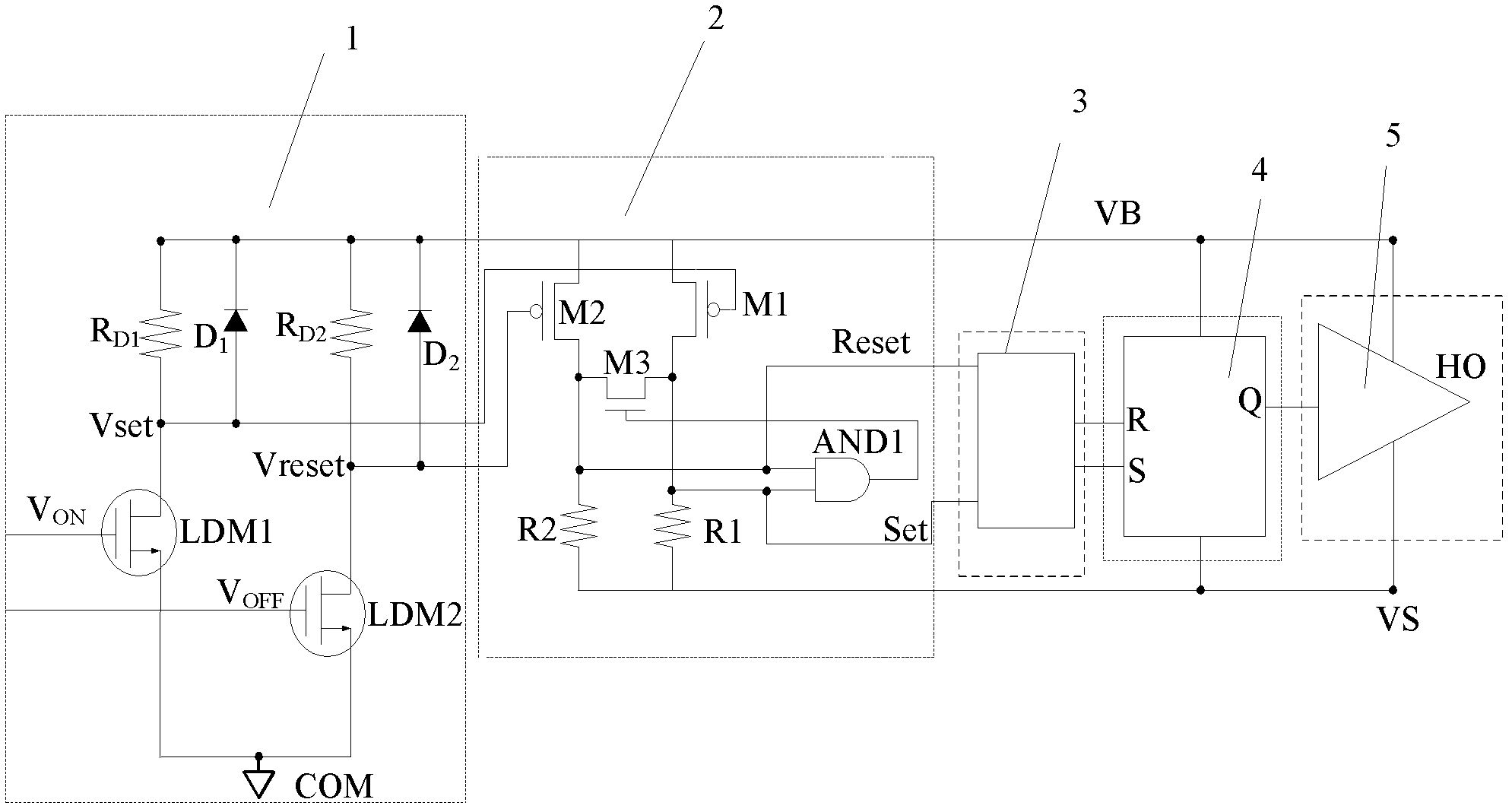

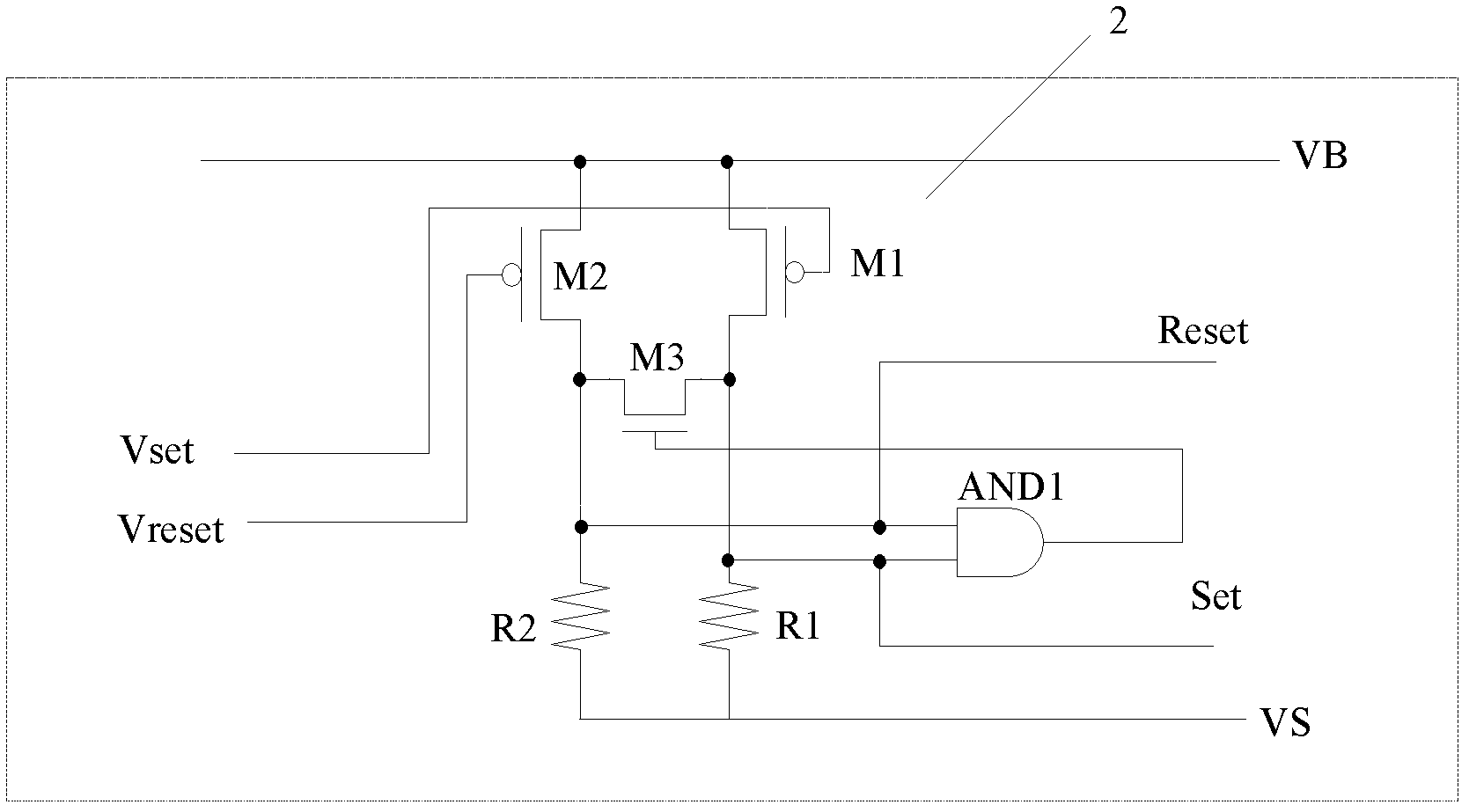

[0021] like figure 1 and figure 2 As shown, a high-voltage side gate drive circuit that can resist common-mode noise interference includes a high-voltage level shift circuit 1, a logic filter circuit 3, an RS flip-flop 4, and an output driver stage circuit 5, wherein the high-voltage level shift circuit The input of 1 is provided by the low-voltage side pulse generating circuit, the output of the logic filter circuit 3 enters the output driver stage circuit 5 through the RS flip-flop 4, and a voltage conversion clamp is set between the high-voltage level shift circuit 1 and the logic filter circuit 3 Circuit 2, the output of the high-voltage level shift circuit 1 is connected to the input end of the voltage conversion clamp circuit 2, the output end of the voltage conversion clamp circuit 2 is connected to the input end of the logic filter circuit 3, and the voltage conversion clamp circuit 2. It consists of PMOS transistor M1, PMOS transistor M2, NMOS transistor M3, resisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com