Working attaching chuck device and work piece laminating machine

A technology for workpieces and chucks, which is applied in the field of work adhesion chuck devices and workpiece laminating machines, can solve problems such as difficult to fully separate, and achieve the effects of improved peeling performance, cost reduction, and large peeling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

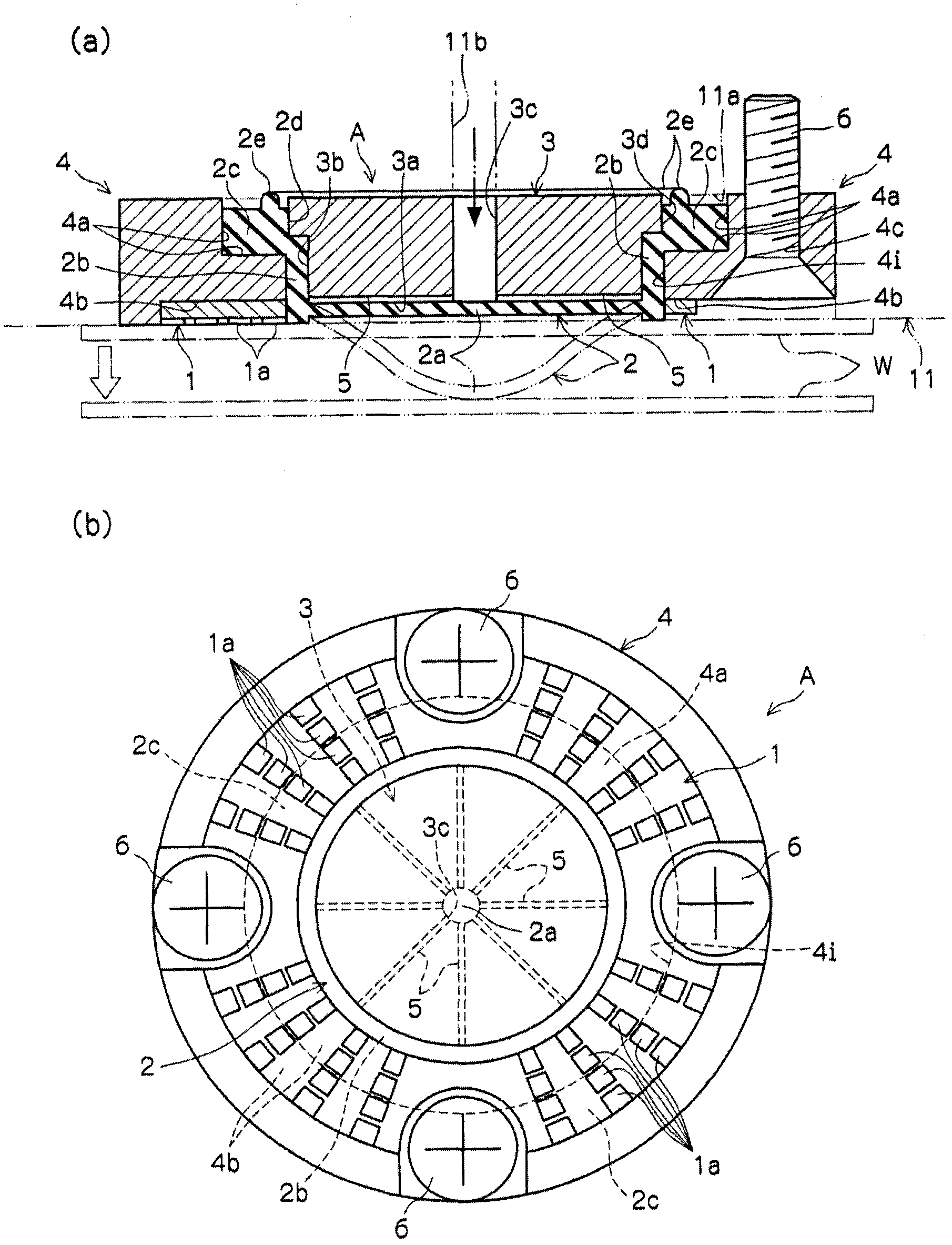

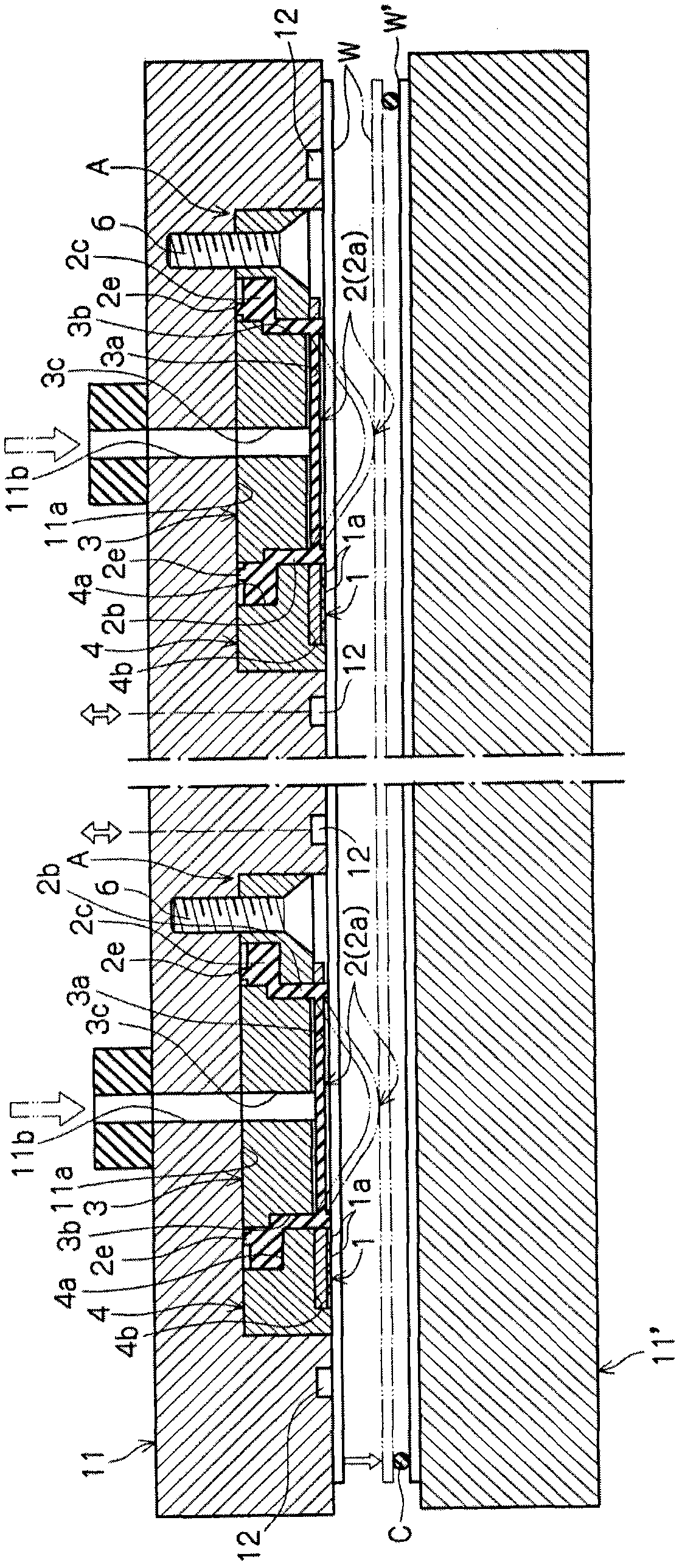

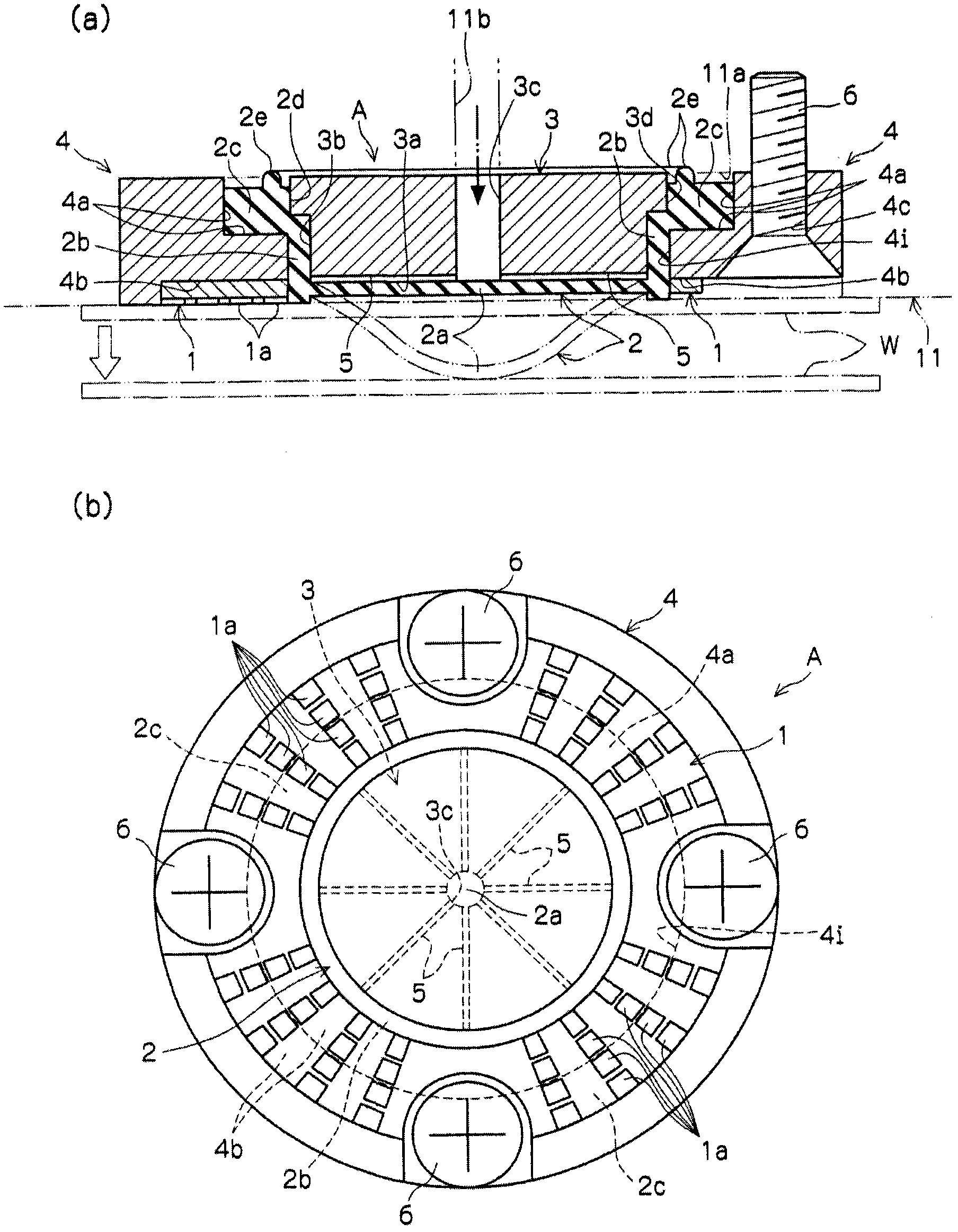

[0065] The example is as follows: figure 1 (a)(b) and figure 2As shown, the concave portion 11a formed on the surface of the holding plate 11 is fitted into the annular member 4 of the workpiece adhesion chuck device A, and the workpiece adhesion chuck device A is mounted on the holding plate 11 with a mounting member 6 such as a bolt. A fluid such as compressed air is supplied to the channel 3c of the supporting member 3 from the air hole 11b dug in the holding plate 11, so that the deformed portion 2a of the peeling member 2 expands and deforms, and is forced to be peeled off by pressing and adhered by the adhesive surface 1a. Hold the plate-shaped workpiece W.

[0066] On the outside of the passage 3c, an annular seal portion 2e is formed so as to surround the outer periphery of the support member 3 and block the flow passage from the passage 3c to the annular member 4. As shown in FIG.

[0067] In the illustrated example, the ring-shaped sealing portion 2e is integrally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com