Olefin hydroformylation method

A hydroformyl and alkene technology, which is applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve the problems of low selectivity of target products and low reaction conversion rate, optimize effective distribution, and improve reaction efficiency. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

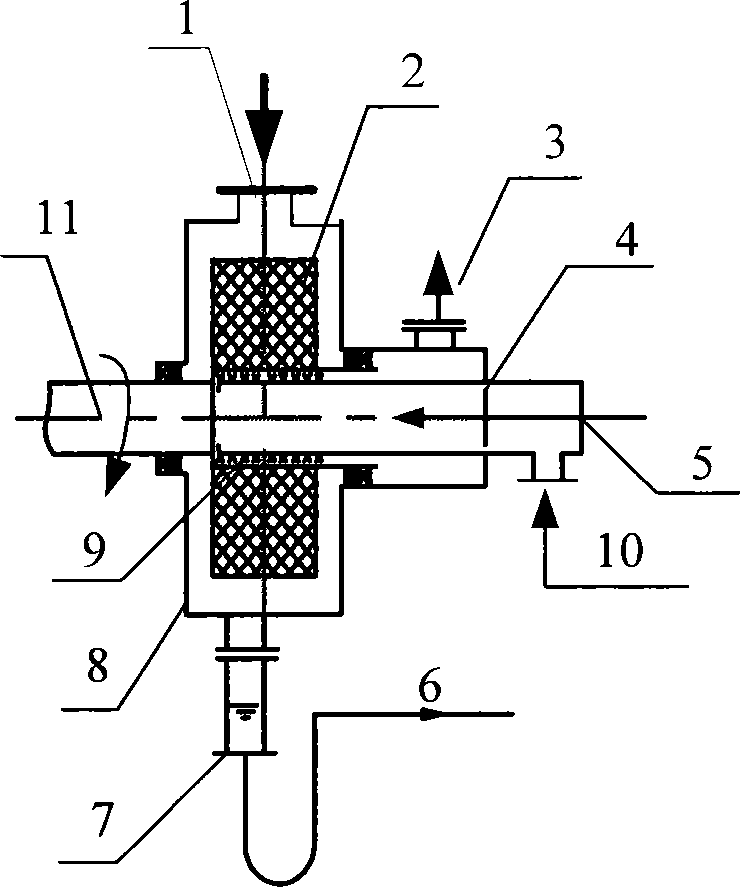

[0025] Attached figure 1 The shown device adopts the rhodium catalyst prepared in Example 1 of the document CN200510085899.2 as the catalyst, and the olefin is selected from propylene, and the molar ratio of hydrogen: CO: propylene: Rh is 1: 1: 0.8 in terms of total moles. : 0.2; under the condition that the molar ratio of the first mixed gas of hydrogen, CO and propylene to the second mixed gas of hydrogen, CO and propylene is 20:1, the first mixed gas, the second mixed gas and the components containing liquid catalyst are respectively introduced from the first gas inlet 1, the second gas inlet 10 and the liquid inlet 4 into the method of hydroformylation of olefins in the rotating packing layer 2, the rotating packing layer rotating speed is adjusted to 1000rpm, and the The liquid catalyst-containing component introduced by the liquid inlet line 5 is merged with the second gas introduced through the second gas inlet 10 and then introduced into the liquid inlet 4 of the metho...

Embodiment 2

[0027] Attached figure 1 The shown device adopts the rhodium catalyst prepared in the embodiment 2 of the document CN200510085899.2 as the catalyst, and the olefin is selected from butene, and the molar ratio of hydrogen: CO: butene: Rh is 1:1 in terms of total moles. : 0.7: 0.2; under the condition that the molar ratio of the first mixed gas of hydrogen, CO and butene to the second mixed gas of hydrogen, CO and butene is 30:1, the first mixed gas, the second Two streams of mixed gas and components containing liquid catalyst are respectively introduced into olefins from the first gas inlet 1, the second gas inlet 10 and the liquid inlet 4 for hydroformylation in the rotating packing layer 2, and the rotating packing layer speed is adjusted to 500rpm, the liquid catalyst-containing component introduced through the liquid inlet line 5 is merged with the second gas introduced through the second gas inlet 10 and then introduced into the liquid inlet 4 of the method for hydroformyl...

Embodiment 3

[0029] Attached figure 1The shown device adopts the rhodium catalyst prepared in Example 3 of the document CN200510085899.2 as the catalyst, and the olefin is selected from butene, and the molar ratio of hydrogen: CO: butene: Rh is 1:1 in terms of total moles. : 0.85: 0.1; under the condition that the molar ratio of the first mixed gas of hydrogen, CO and butene to the second mixed gas of hydrogen, CO and butene is 30:1, the first mixed gas, the second Two streams of mixed gas and components containing liquid catalyst are respectively introduced into olefins from the first gas inlet 1, the second gas inlet 10 and the liquid inlet 4 for hydroformylation in the rotating packing layer 2, and the rotating packing layer speed is adjusted to 2000rpm, the liquid catalyst-containing component introduced through the liquid inlet line 5 is merged with the second gas introduced through the second gas inlet 10 and then introduced into the liquid inlet 4 of the method for hydroformylation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com