Trans-critical-compression/absorption composite refrigeration device utilizing low-grade heat

A composite refrigeration and low-grade heat technology, which is applied to machines using waste heat, refrigerators, refrigeration and liquefaction, etc., can solve the problems that the refrigeration effect needs to be improved, the isentropic efficiency of the compressor is low, and the construction and maintenance costs are low. Improved utilization efficiency and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

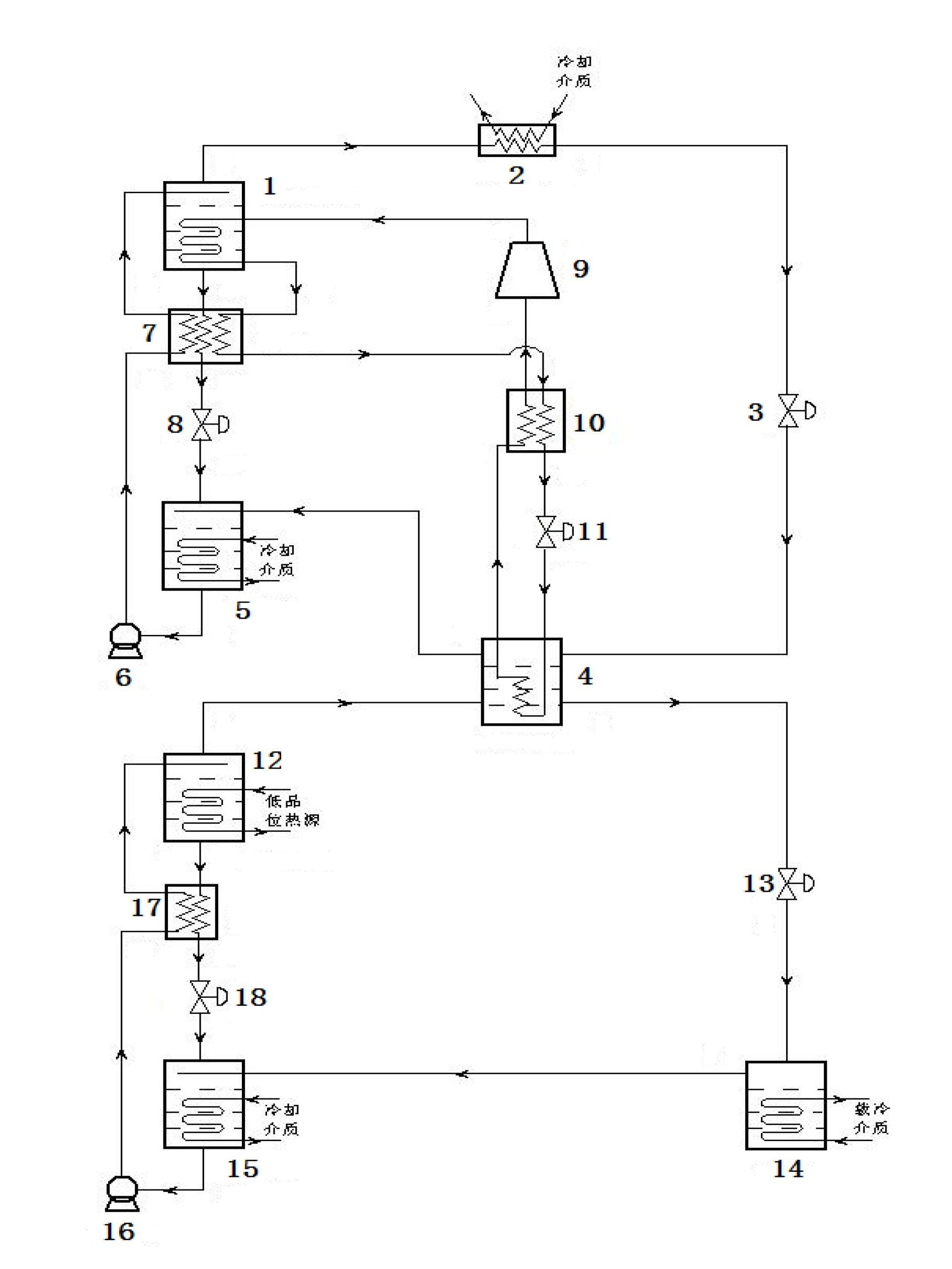

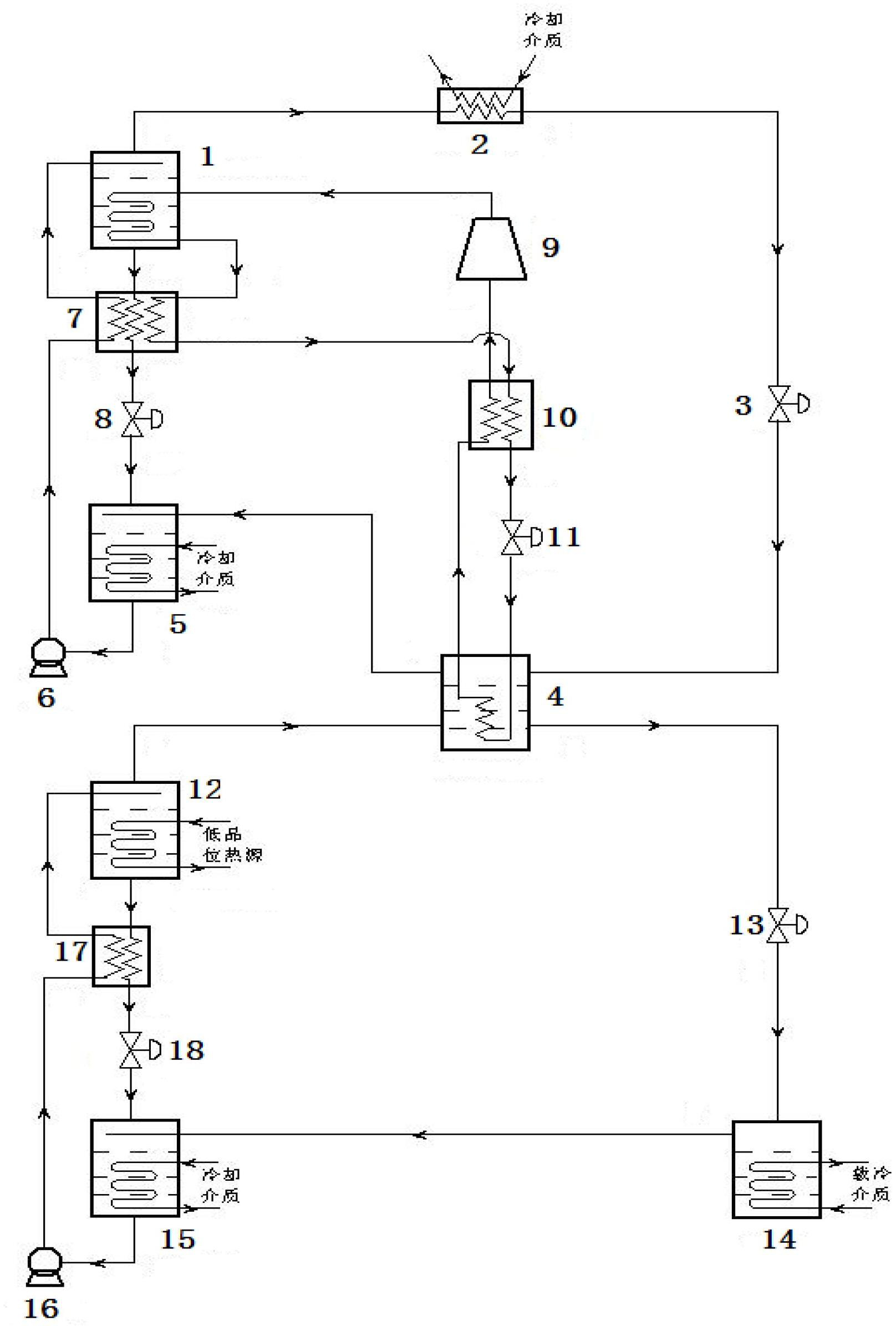

[0037] Such as figure 1 As shown, the present invention is a transcritical / absorption refrigeration composite refrigeration device utilizing low-grade heat, wherein the working fluid of the transcritical circulation subsystem adopts carbon dioxide (the boiling point of R744 is -78.5°C under normal pressure), and the high-pressure absorption refrigeration subsystem The working fluid of the low-pressure stage absorption refrigeration subsystem is lithium bromide aqueous solution, in which water (the boiling point of R718 is 100°C under normal pressure) is the refrigerant. The whole device includes a high-pressure stage absorption refrigeration subsystem, a transcritical circulation subsystem and a low-pressure stage absorption refrigeration subsystem.

[0038] The steam outlet of the high-pressure generator 1 of the high-pressure stage absorption refrigeration subsystem is connected to the inlet of the condenser 2, the outlet of the condenser 2 is connected to the inlet of the f...

Embodiment 2

[0053] The transcritical circulation subsystem uses carbon dioxide as the working fluid, and the working fluid of the high-pressure stage absorption refrigeration subsystem and the low-pressure stage absorption refrigeration subsystem is ammonia solution, in which ammonia (R717 has a boiling point of -33.5°C under normal pressure) is the refrigerant. The structure of the refrigerating device, the connection mode of each component and the working process are the same as those in Embodiment 1.

[0054] In this embodiment, low-grade heat of about 80-100°C is used to obtain refrigeration at -20-5°C, and the utilization efficiency of electric energy is increased by about 30-65%, and the utilization efficiency of low-grade heat energy is increased by about 25-50%.

Embodiment 3

[0056] The transcritical circulation subsystem uses carbon dioxide as the working fluid; the working fluid of the high-pressure stage absorption refrigeration subsystem and the low-pressure stage absorption refrigeration subsystem is a mixture of tetrafluoroethane (R134a) and dimethylformamide (DMF), of which tetrafluoroethane Ethane (the boiling point of R134a under normal pressure is -26.26°C) is the refrigerant. The structure of the refrigerating device, the connection mode of each component and the working process are the same as those in Embodiment 1.

[0057] In this embodiment, low-grade heat of about 50-70°C is used to obtain refrigeration at -20-5°C, and the utilization efficiency of electric energy is increased by about 20-45%, and the utilization efficiency of low-grade heat energy is increased by about 35-60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com