Conveying device

A technology of conveying device and conveying direction, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., which can solve problems such as high weight, difficulty in conveying and installing conveyors, unsatisfactory vibration and vibration damping characteristics, etc., to achieve Efficiency and low-vibration conveying process High, simple construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

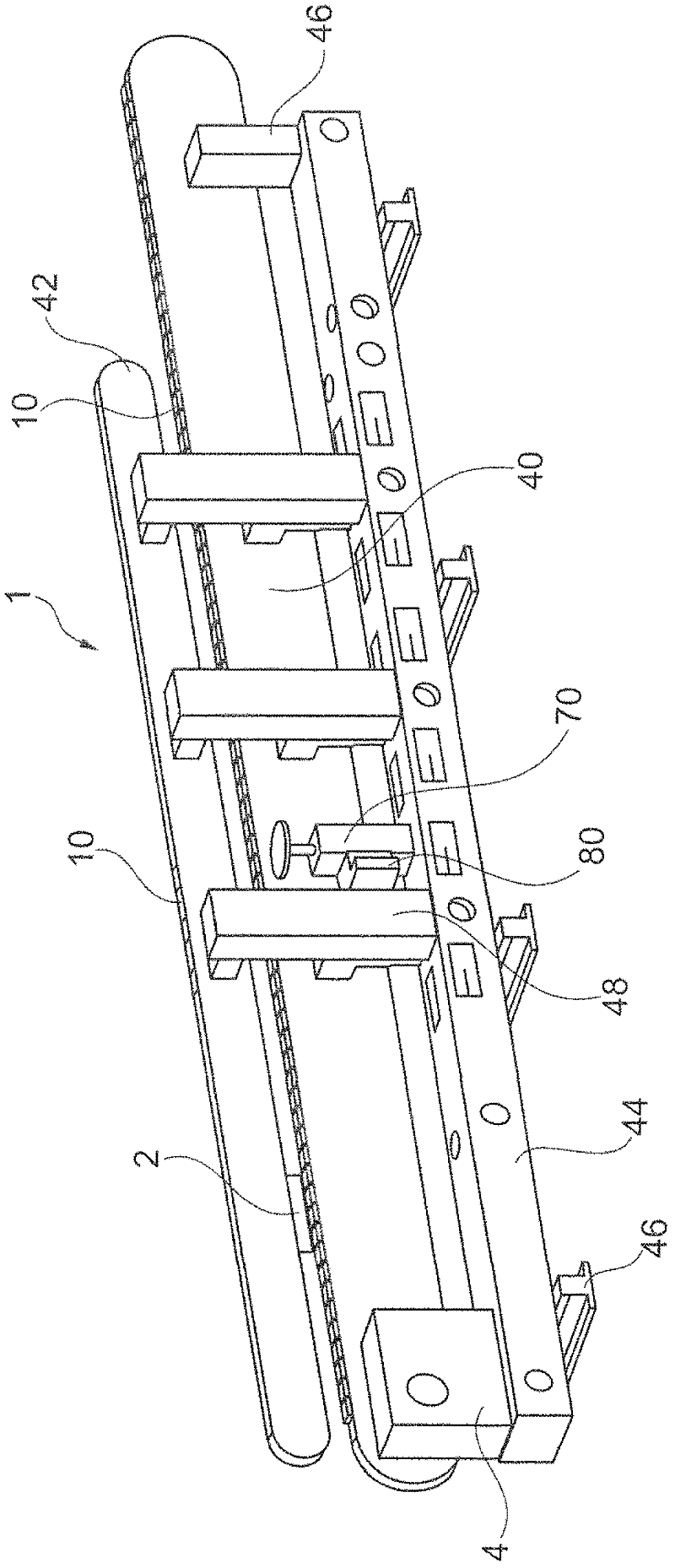

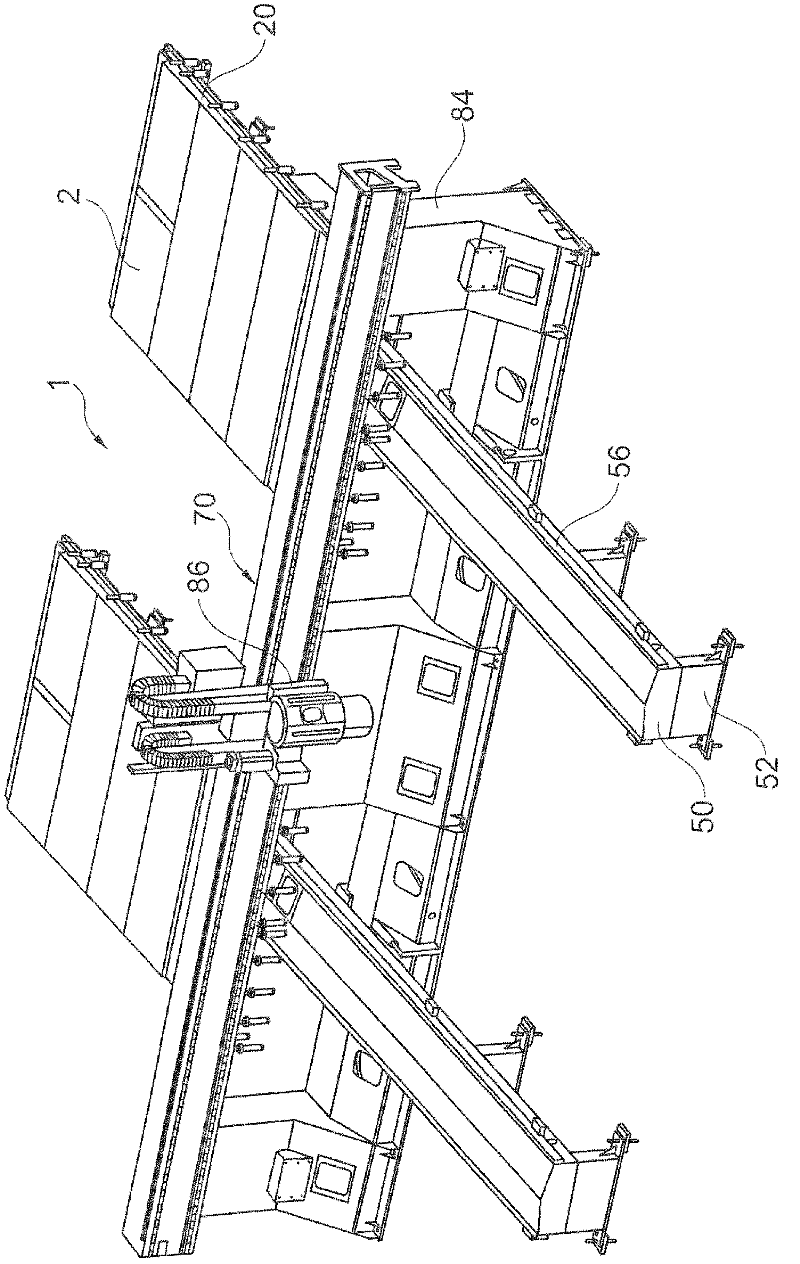

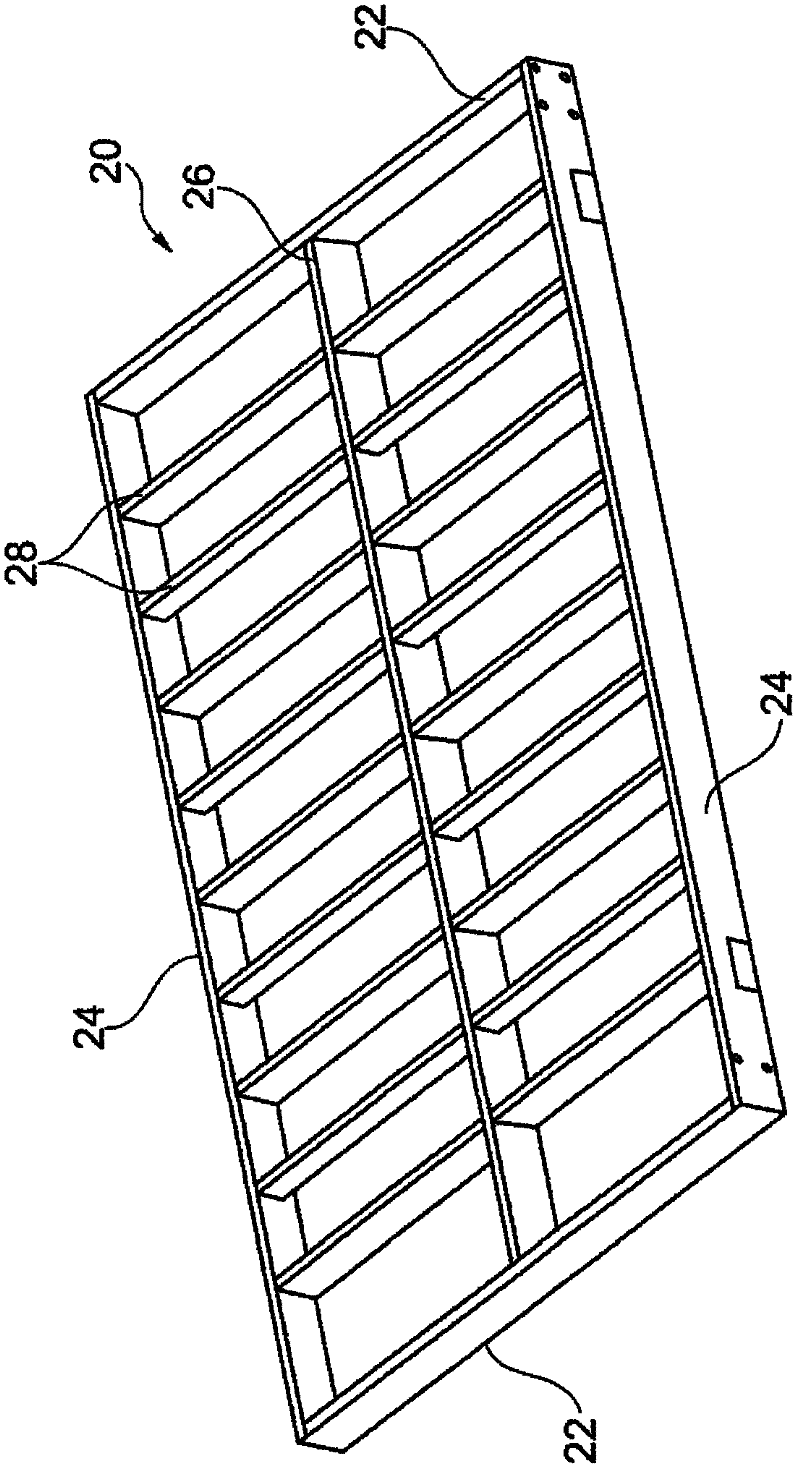

[0021] The following preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. exist figure 1 A schematic perspective view of a device 1 for conveying workpieces 2 in a conveying direction and for synchronously processing them is shown schematically in . It should be pointed out here that the plant 1 shown as plant 1 can be designed not only as a pure conveying plant, but also as a combined conveying and processing plant. Like the other devices described below, the device 1 here is preferably used for conveying and optionally processing workpieces at least partially made of wood, wood, plastic or the like, as in the field of the furniture and component industry, for example widely used.

[0022] exist figure 1 The apparatus 1 shown in , initially comprises a conveying device 10 which in this embodiment is designed as an infinitely rotating element in the form of a so-called magnetic chain. It should be not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com