Preparation method of Fischer-Tropsch synthesis precipitated iron catalyst

A Fischer-Tropsch synthesis and catalyst technology, which is used in the preparation of liquid hydrocarbon mixtures, chemical instruments and methods, catalysts for physical/chemical processes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

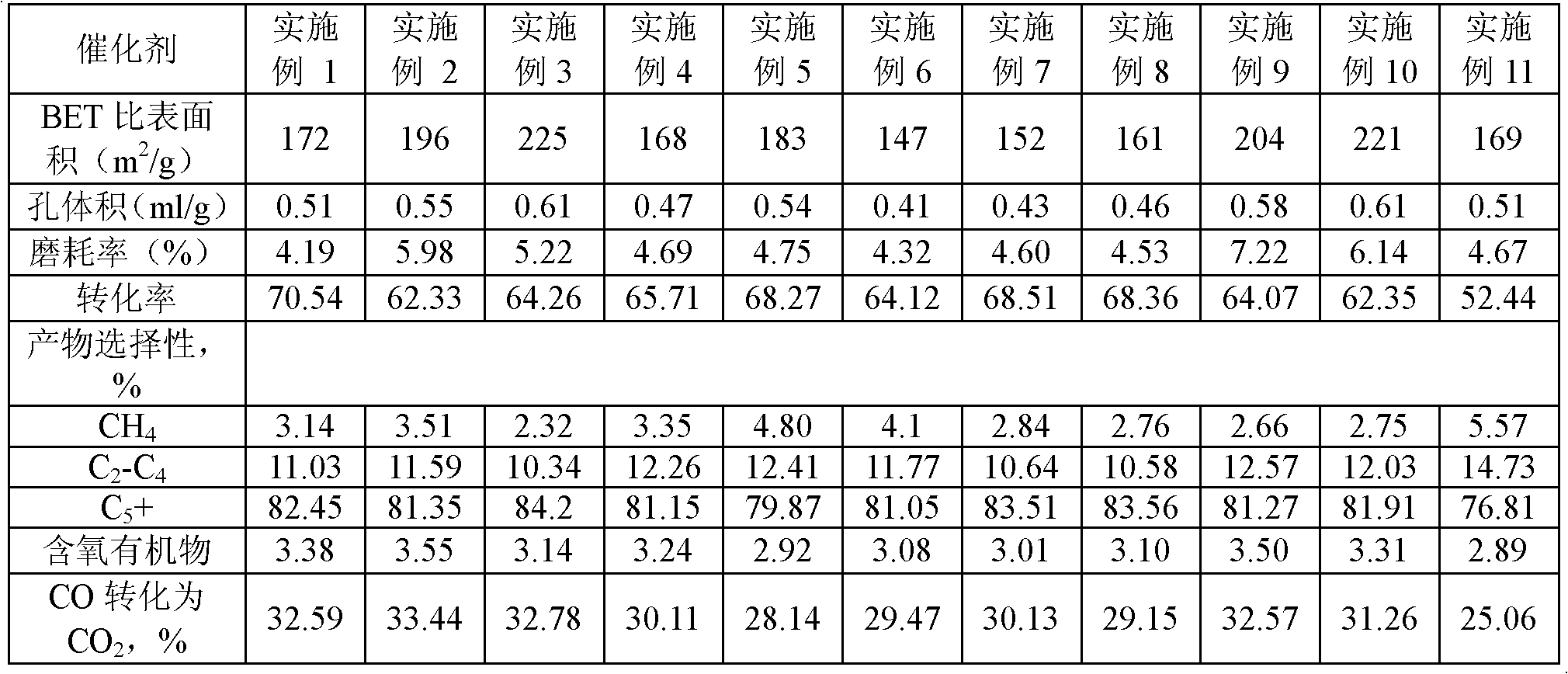

Examples

preparation example Construction

[0021] According to a typical implementation of the present invention, the preparation method of the Fischer-Tropsch synthesis precipitated iron catalyst comprises the following steps: 1) Feed the iron salt solution, the first auxiliary salt solution, the precipitant solution and the silicon compound solution into the In the precipitation reactor, a co-precipitation reaction is carried out to obtain a precipitation slurry; 2) the precipitation slurry is filtered and washed to obtain a catalyst precursor filter cake, and the catalyst precursor filter cake is slurried to obtain a catalyst precursor slurry ; 3) carry out co-current reaction with silicon compound solution and nitric acid solution to obtain silica sol; 4) mix catalyst precursor slurry with silica sol, and filter to obtain filter cake; 5) use deionized water or deionized The mixed solution of water and the second auxiliary agent salt solution reslurries the filter cake to obtain a catalyst slurry; and 6) spray-dries,...

Embodiment 1

[0059]Add 20Kg of deionized water to catalyst precursor filter cake 2, and beat for 0.5-1 hour under high-speed stirring. Silica sol 1 was left to stand for 10 minutes after the reaction, added to the slurry, mixed under high-speed stirring for 20 minutes, and then filtered. The obtained filter cake was reslurried with a certain amount of deionized water containing 0.049 Kg of cobalt nitrate, and the stirring was continued for 25 minutes to obtain a catalyst slurry. The catalyst slurry was input into a spray dryer, and spray-dried under the condition that the inlet air temperature was 290°C and the outlet air temperature was 105°C. The obtained microsphere catalyst is heated up to 150°C at 600°C / h in a muffle furnace, kept at this temperature for 7 hours, then raised to 450°C at a rate of 300°C / h, and kept at 450°C for 6 hours to obtain the final catalyst. Good sphericity and surface topography.

Embodiment 2

[0061] Add 20Kg of deionized water to catalyst precursor filter cake 2, and beat for 0.5-1 hour under high-speed stirring. Silica sol 2 was left to stand for 1 hour after the reaction, and then added to the slurry while controlling the mixing temperature at 25°C and mixing for 25 minutes under high-speed stirring. The pH value is adjusted to be about 8 by adding ammonia water, and the adding time is controlled to be 50 minutes, and then filtering is performed. The obtained filter cake was reslurried with a certain amount of deionized water containing 0.055Kg of cobalt nitrate and 0.018Kg of potassium nitrate, and the stirring was continued for 35 minutes to obtain a catalyst slurry. The catalyst slurry was input into a spray dryer, and spray-dried under the condition that the inlet air temperature was 290°C and the outlet air temperature was 105°C. The obtained microsphere catalyst is heated in a muffle furnace at a rate of 500°C / h to 150°C, kept at this temperature for 10 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com