Biomass magnetic carbon material for degrading organic dye

A technology of organic dyes and carbon materials, applied in the direction of inorganic chemistry, alkali metal compounds, chemical/physical processes, etc., can solve the problems of high preparation cost, unsuitable for large-scale preparation, complicated process, etc., achieve high specific surface area, repeated use Good effect and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

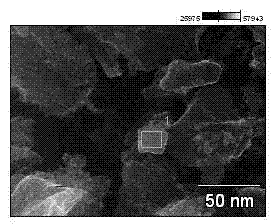

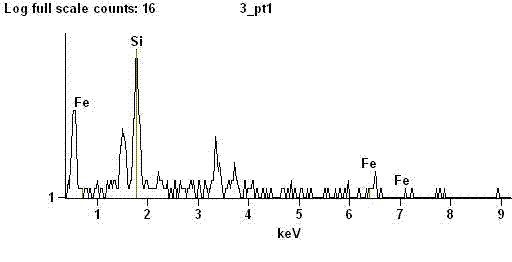

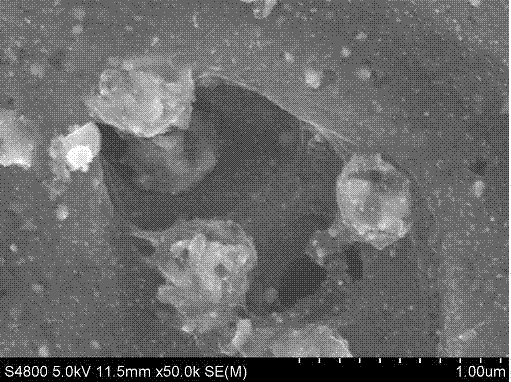

Image

Examples

Embodiment 1

[0038] Example 1 A biomass magnetic carbon material for degrading organic dyes, which is made by mixing biological raw materials and iron precursors at a ratio of 15kg:1kg.

[0039] Wherein: the iron precursor is ferric ammonium oxalate. Biological raw material refers to peanut shells.

[0040] The preparation method of the biomass magnetic carbon material of the degradation organic dye comprises the following steps:

[0041] ⑴ Weigh according to the ratio.

[0042] ⑵ Grinding the biological raw material to 100-200 mesh to obtain the crushed raw material;

[0043] (3) dissolving the iron precursor in water at a ratio of 1kg:70L to obtain an aqueous solution containing the iron precursor;

[0044] (4) fully immersing the pulverized raw material in the aqueous solution containing the iron precursor, and obtaining the soaked raw material after 10 hours;

[0045] (5) The impregnated raw materials are dried at a temperature of 80° C. to constant weight to obtain dried raw ...

Embodiment 2

[0049] Example 2 A biomass magnetic carbon material for degrading organic dyes, which is made by mixing biological raw materials and iron precursors at a ratio of 10kg:1kg.

[0050] Among them: the iron precursor is a mixture of ferric ammonium oxalate and copper nitrate, and the mass ratio of ferric ammonium oxalate to copper nitrate is 90 kg:10 kg. Biological raw material refers to straw.

[0051] The preparation method of the biomass magnetic carbon material of the degradation organic dye comprises the following steps:

[0052] ⑴ Weigh according to the ratio.

[0053] ⑵ Grinding the biological raw material to 100-200 mesh to obtain the crushed raw material;

[0054] (3) dissolving the iron precursor in water at a ratio of 1kg:40L to obtain an aqueous solution containing the iron precursor;

[0055] (4) fully immersing the pulverized raw material in the aqueous solution containing the iron precursor, and obtaining the soaked raw material after 8 hours;

[0056] (5) ...

Embodiment 3

[0060] Example 3 A biomass magnetic carbon material for degrading organic dyes, which is made by mixing biological raw materials and iron precursors at a ratio of 2kg:1kg.

[0061] Among them: the iron precursor is a mixture of ferric ammonium oxalate and manganese nitrate, and the mass ratio of ferric ammonium oxalate to manganese nitrate is 90 kg:10 kg. Biological feedstock refers to corn cobs.

[0062] The preparation method of the biomass magnetic carbon material of the degradation organic dye comprises the following steps:

[0063] ⑴ Weigh according to the ratio.

[0064] ⑵ Grinding the biological raw material to 100-200 mesh to obtain the crushed raw material;

[0065] (3) dissolving the iron precursor in water at a ratio of 1kg:10L to obtain an aqueous solution containing the iron precursor;

[0066] (4) fully immersing the pulverized raw material in the aqueous solution containing the iron precursor, and obtaining the soaked raw material after 6 hours;

[0067...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com