Steel plate edge R2 convex circular bead edge milling machine

An edge milling machine and steel plate technology, applied in milling machine equipment, details of milling machine equipment, metal processing machinery parts, etc. High precision, reduced energy consumption, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

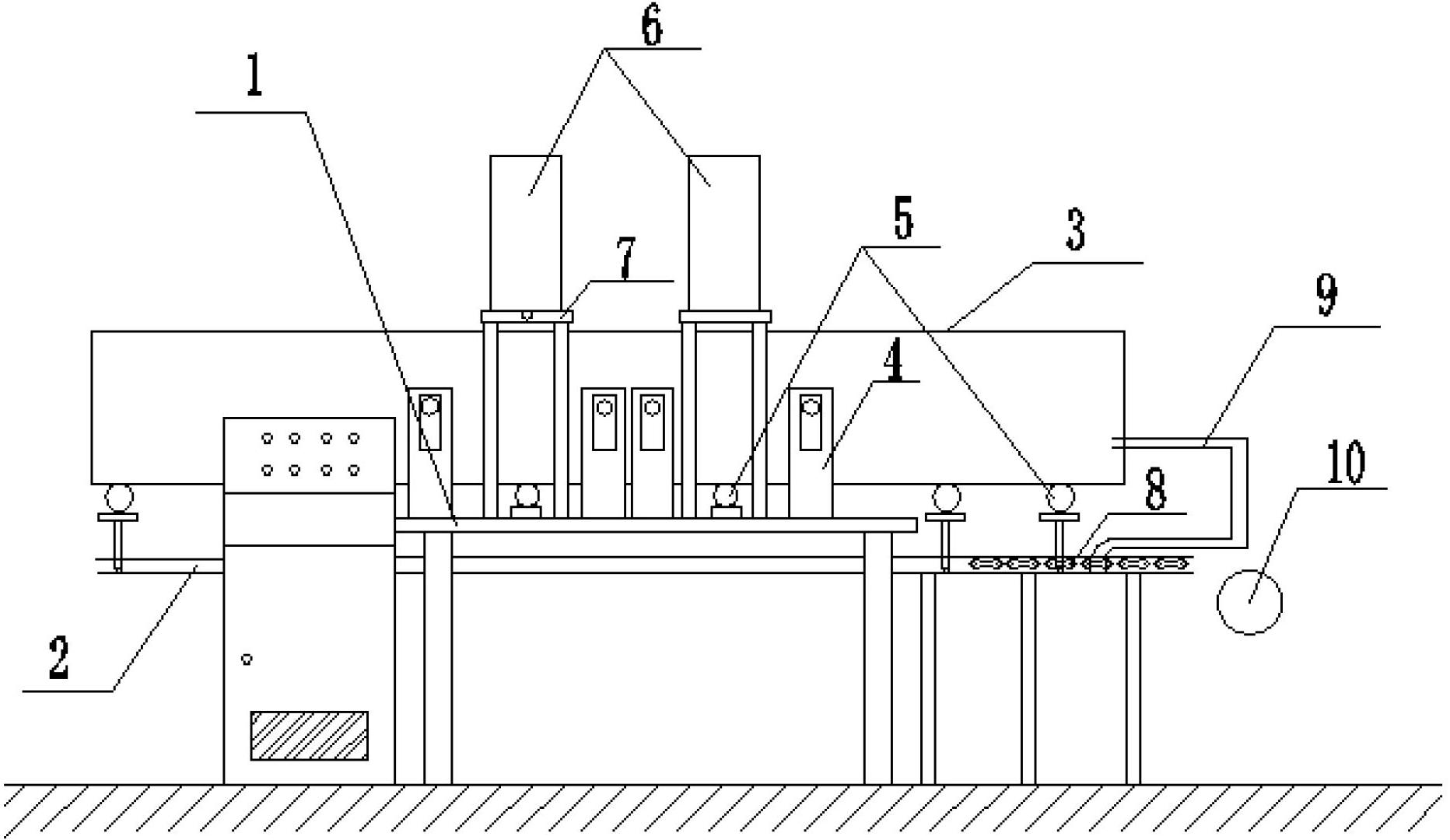

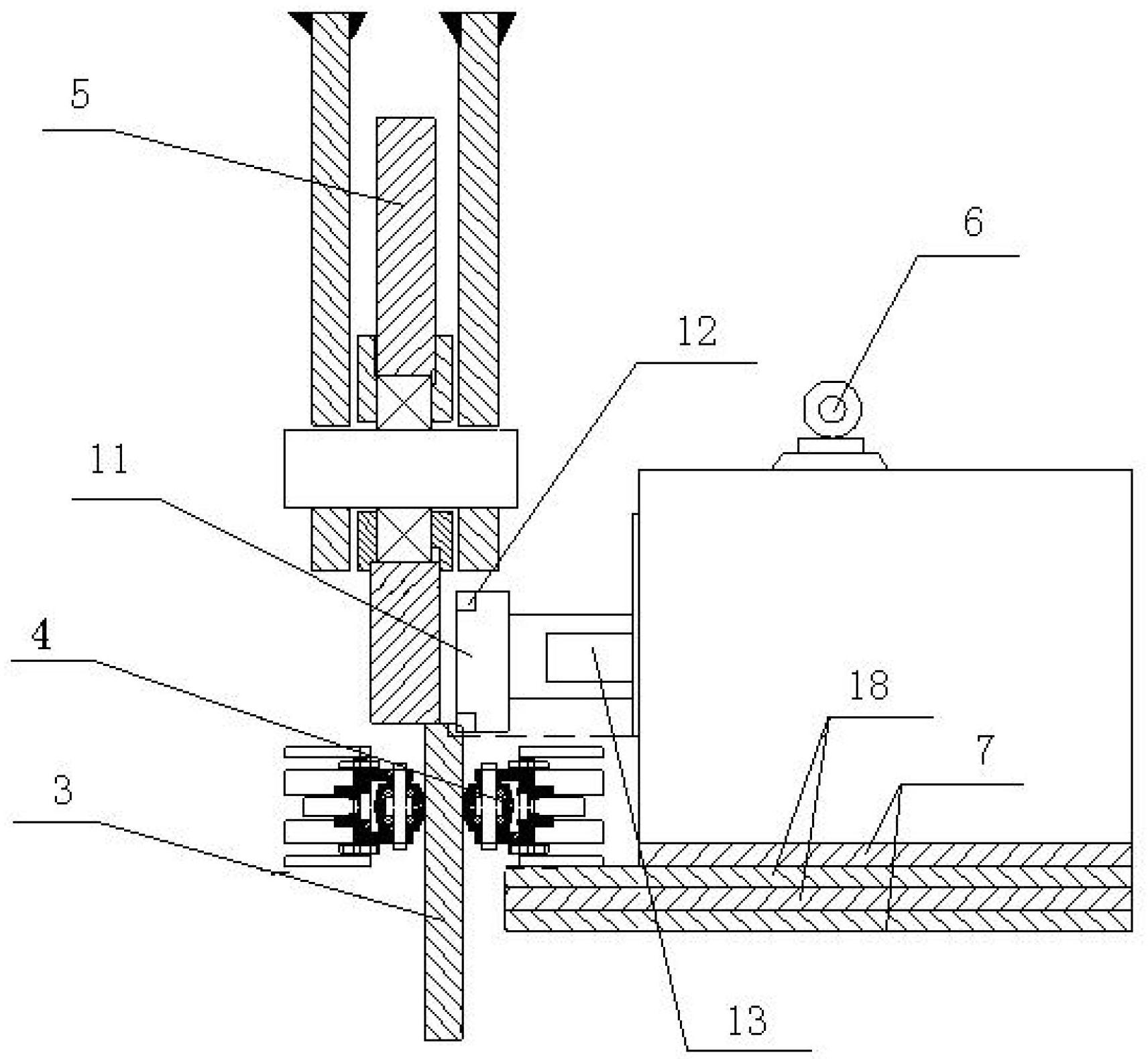

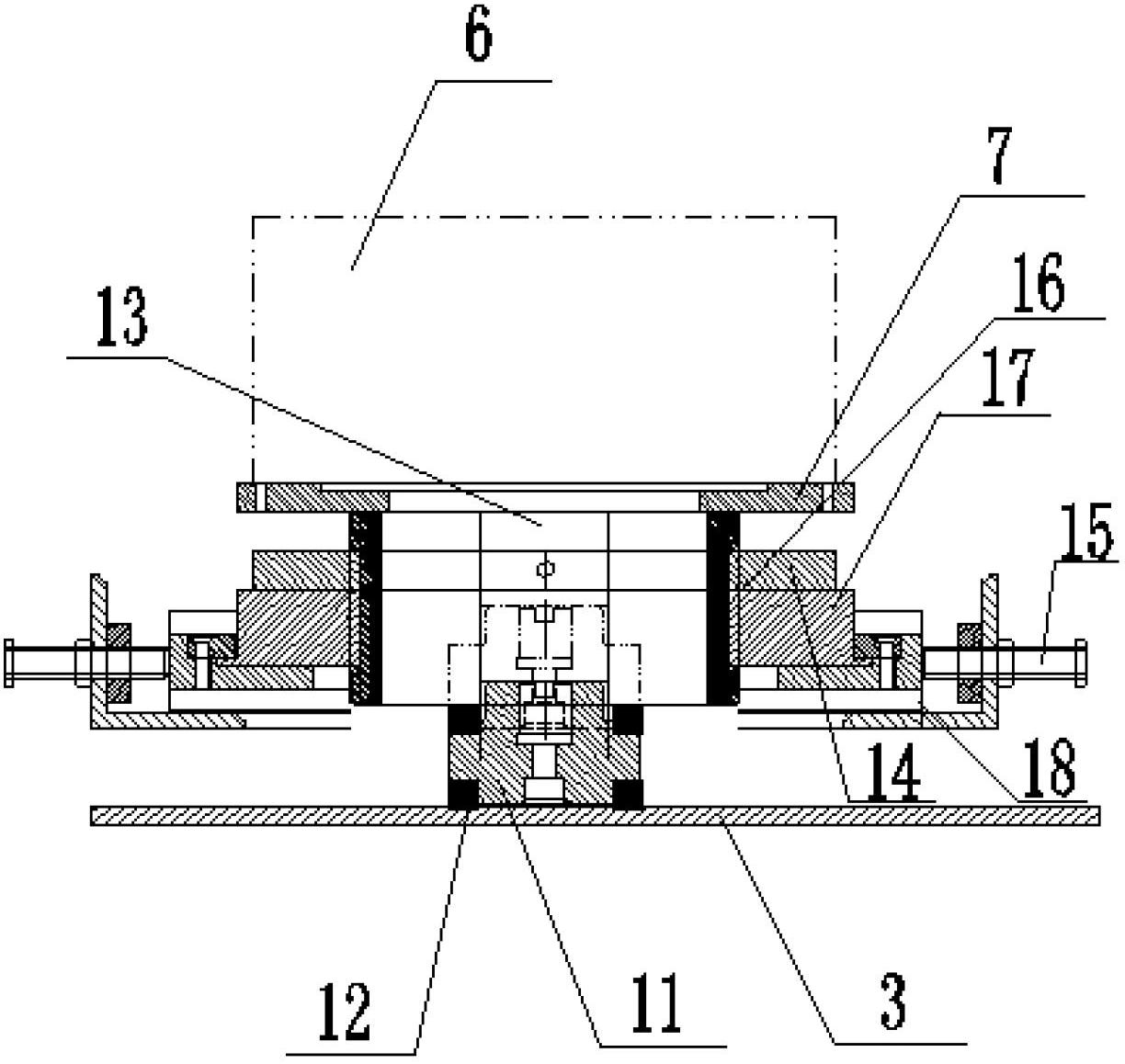

[0025] refer to Figure 1 to Figure 5 , a steel plate edge R2 convex fillet edge milling machine mainly includes a working platform. The working platform includes a main working platform 1 and a feed working platform 2 , and the feeding working platform 2 is fixed on the bottom surface of the main working platform 1 . A cutting device is installed on the main working platform 1 . Cutting device comprises main motor 6 and milling cutter head 11, and the quantity of cutting device is two sets. A motor base 7 is installed on the main working platform 1, and a main motor 6 is installed on the motor base 7. The main motor 6 is connected with the milling cutter head 11 through the connecting shaft 13 , and the main motor 6 controls the rotation of the milling cutter head 11 . A blade 12 is installed on the milling cutter head 11, and the blade 12 contacts with the edge of the steel plate 3 to be processed. Blade 12 is that the four feet of rectangular blade are processed into R2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com