Deep hole machining device

A processing device and deep hole technology, applied in the field of deep hole processing devices, can solve the problems of difficult chip discharge, increased cutting temperature, poor machinability, etc., and achieve high surface roughness and machining accuracy, compact device structure, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

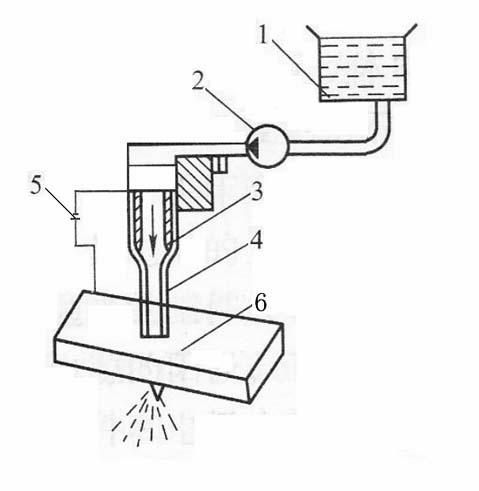

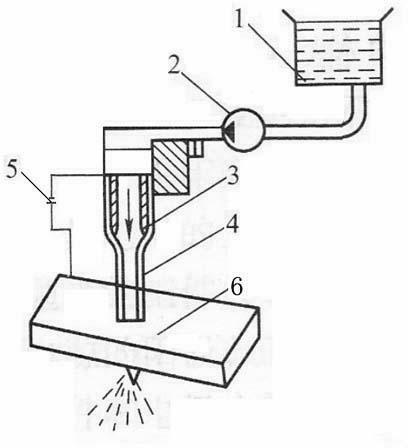

[0008] like figure 1 As shown, a deep hole processing device according to the present invention includes an electrolyte tank 1, a high-pressure liquid pump 2, a cathode 3, an insulating tube 4 and a power supply 5.

[0009] The output end of the electrolyte tank 1 is connected to the input end of the high-pressure liquid pump 2, and the output end of the high-pressure liquid pump 2 is connected to the insulating tube 4. A cathode 3 is arranged in the insulating tube, and the cathode 3 is connected to the power supply. The input end of 5 is connected, and the output end of power supply 5 is connected with workpiece 6.

[0010] Electrolyte is provided in the electrolyte tank 1 .

[0011] Because the workpiece density and surface shape are different from the tool used as an electrode, the distance between each point on the workpiece and the tool surface is also different. The closer the distance passes, the higher the current density, the higher the tassel of the electrolyte, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap