Novel hoisting tool

A lifting tool and a new type of technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of large space occupied by clips, damage, and hidden dangers of falling off, so as to increase the effective use of space, long service life, and ensure safety and tightness. The effect of fixing and lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The description of the following embodiments in conjunction with the accompanying drawings will be more helpful for the public to understand the present invention, but the specific embodiments given by the applicant cannot and should not be regarded as limitations on the technical solutions of the present invention, and any components or technical features Any change to the definition of, or a formal but not substantial change to the overall structure should be regarded as the protection scope defined by the technical solution of the present invention.

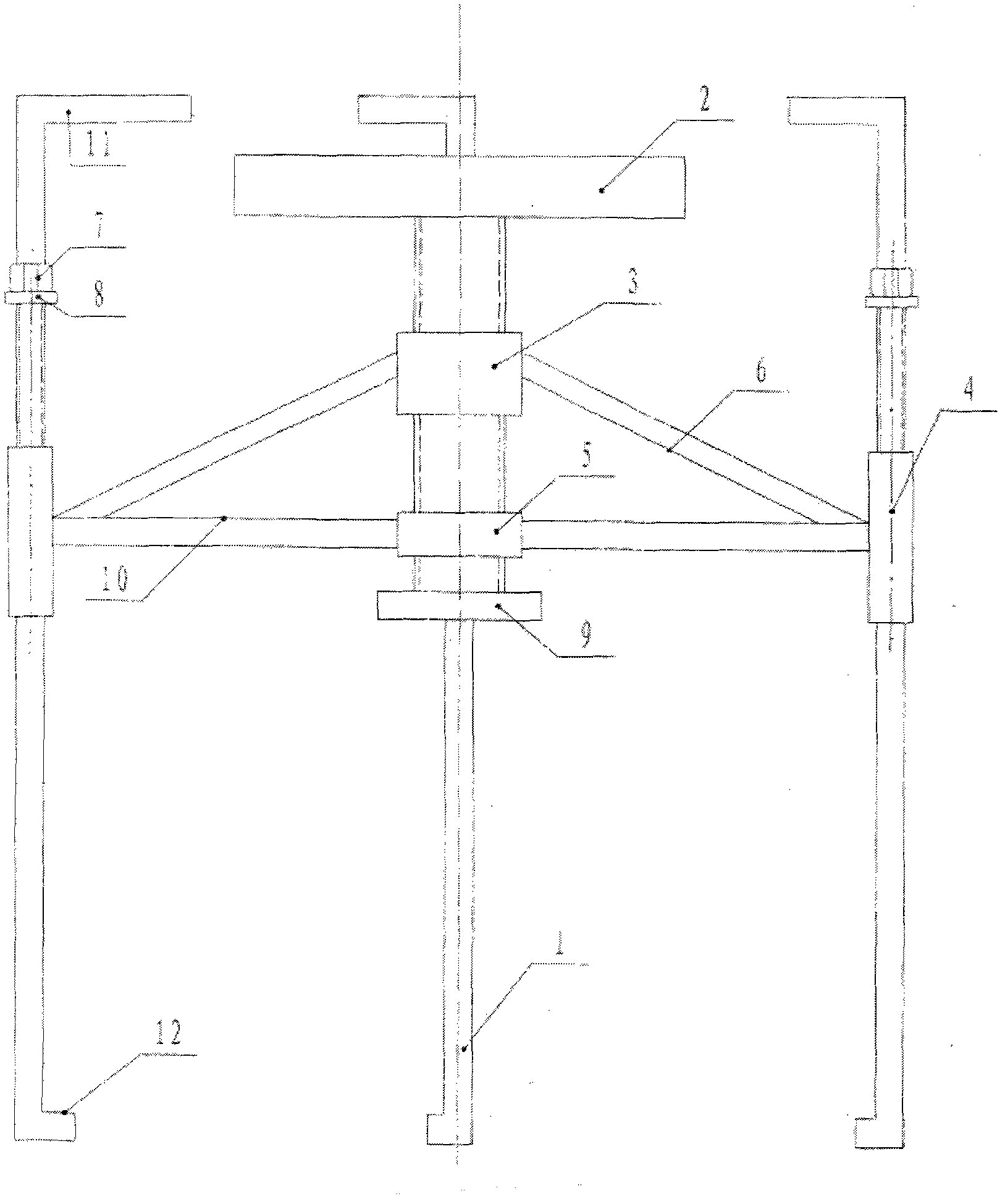

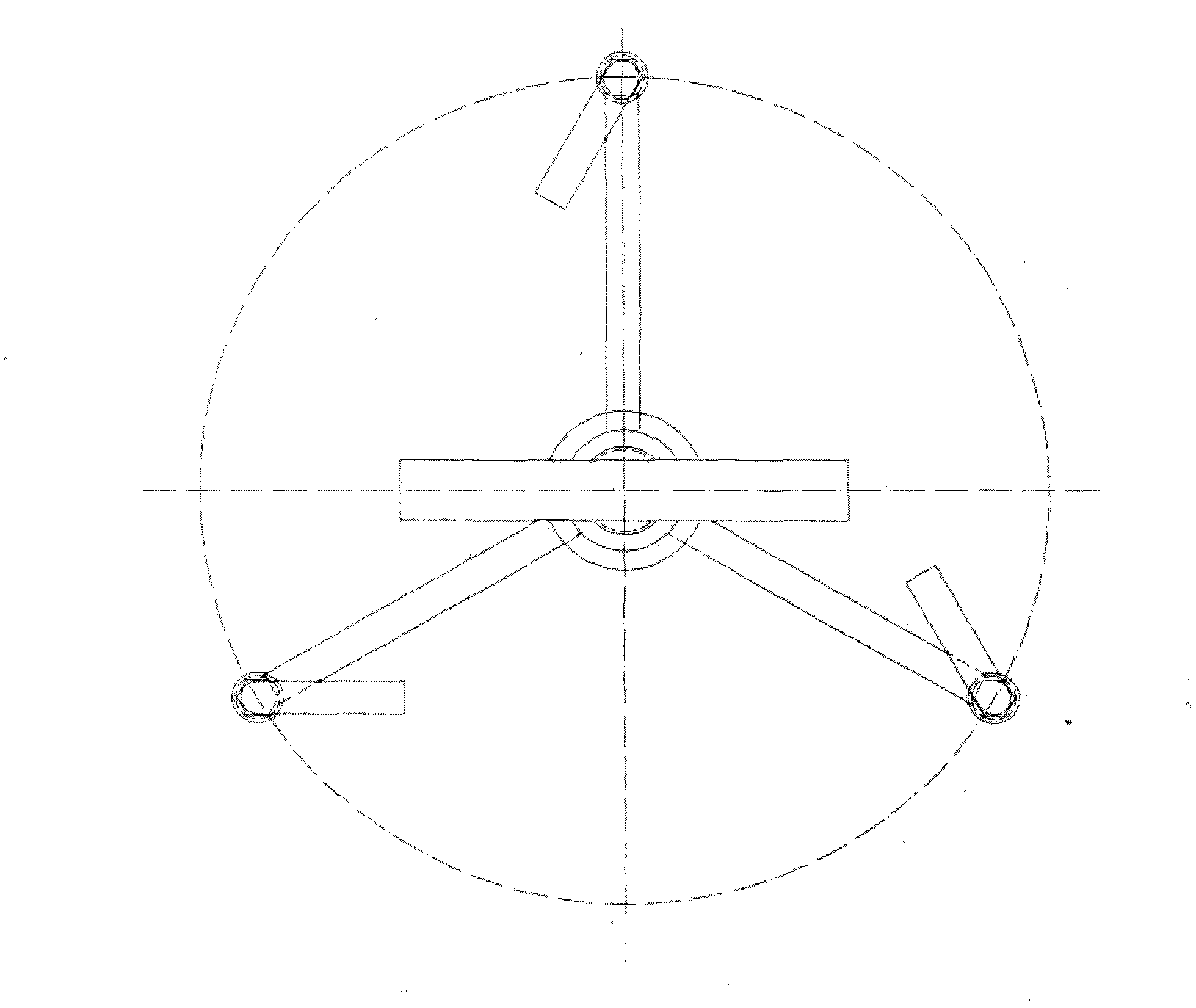

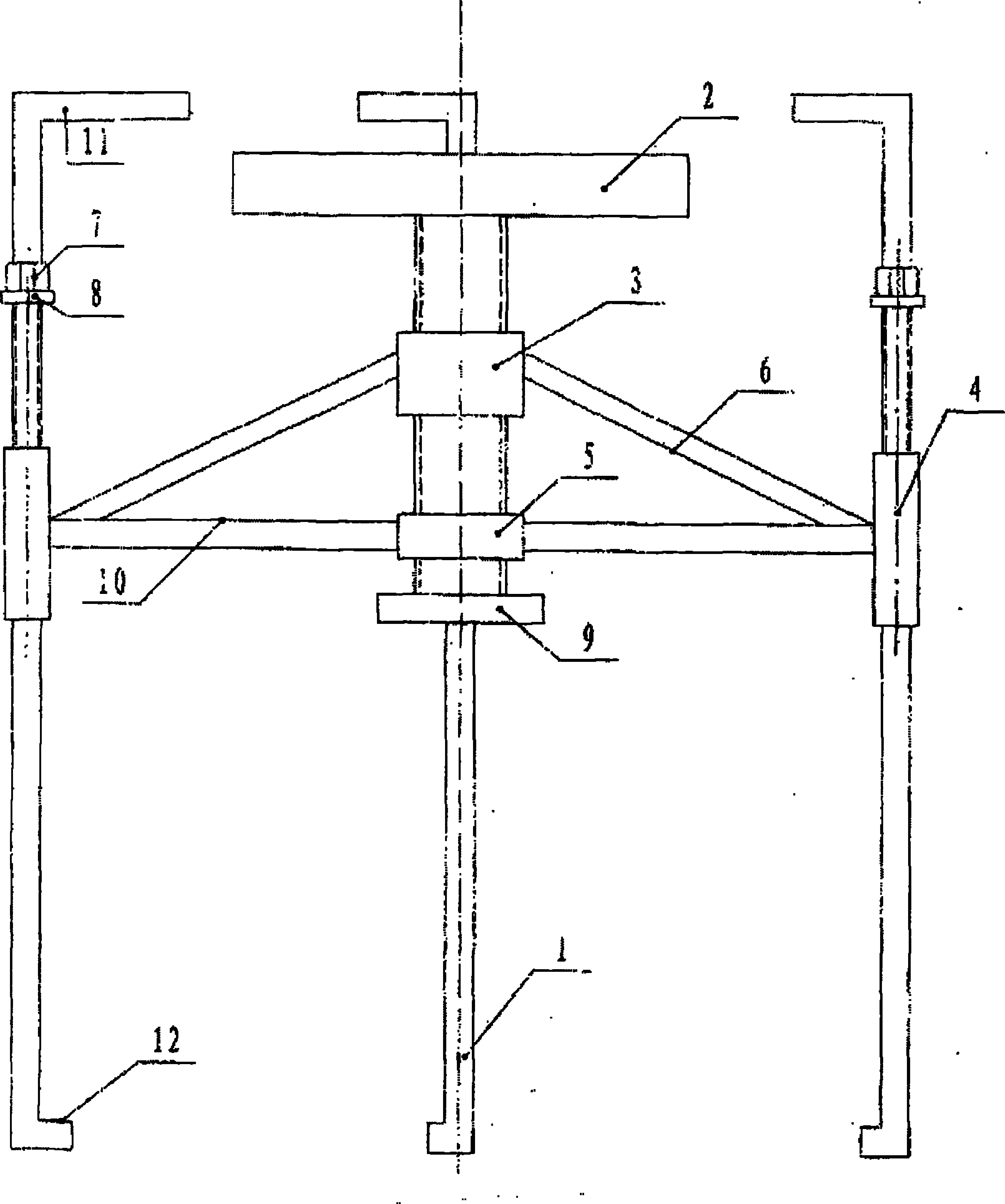

[0012] Such as figure 1 The specific embodiment of the present invention is shown: according to the given inner diameter of the furnace and the available space size, welding a nut 3 in the middle, a positioning sleeve 5, three oblique ribs 6, three flat ribs 10, and three mutual sleeves 4 And relative to a circular 120° uniformly distributed bracket, screw the "T"-shaped lead screw 2 threaded with the nut 3 and the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com