Heat superconducting composite phase change energy storage material

A phase change energy storage material and energy storage material technology, applied in the field of composite solid-liquid phase change energy storage materials, can solve problems such as supercooling, low heat exchange rate, and rupture of polymer materials, and achieve the effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

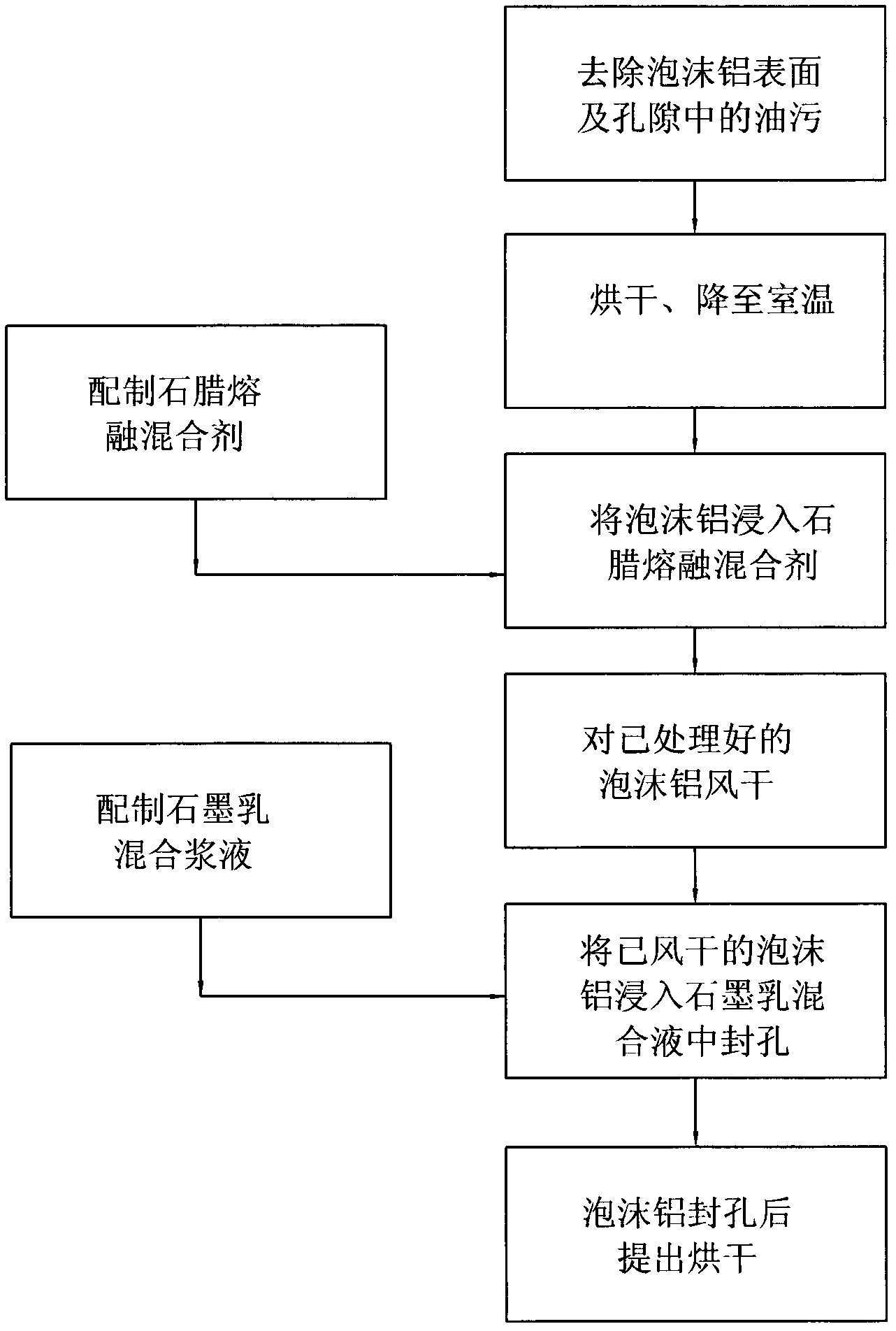

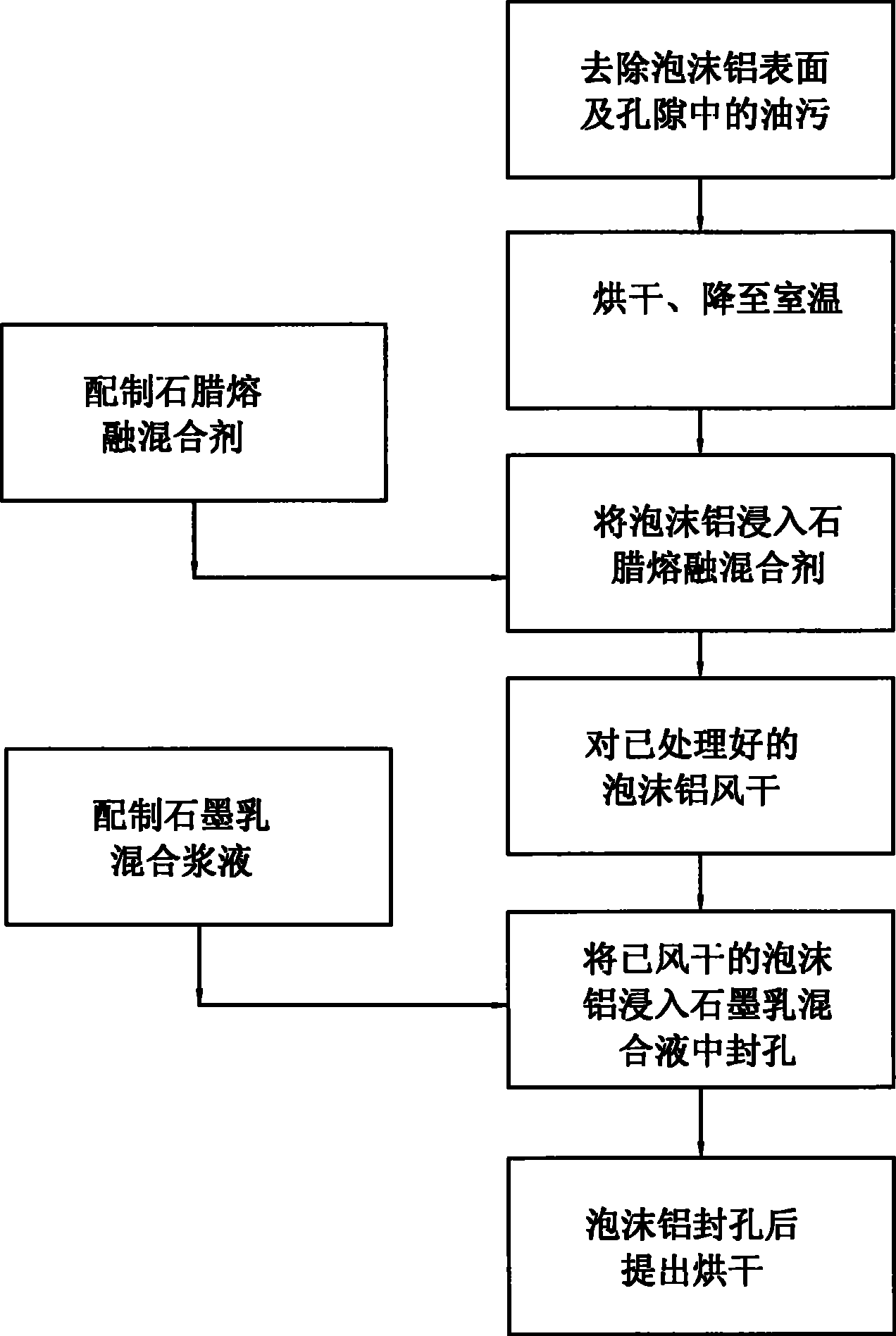

Method used

Image

Examples

Embodiment 1

[0040] The matrix is made of continuous porous metal aluminum foam, the solid-liquid phase change energy storage material is paraffin wax, the sealing material is graphite coating, the aluminum foam is soaked in the paraffin wax mixture for 30 minutes, and the superthermal conductivity composite phase change prepared The adsorption rate of the energy storage material is 77%, the energy storage rate can reach 100J / g, the thermal conductivity is higher than 16W / m.K, and the phase transition point is 130°C to 160°C.

Embodiment 2

[0042] The matrix is made of continuous porous metal aluminum foam, the solid-liquid phase change energy storage material is paraffin wax, the sealing material is graphite coating, the aluminum foam is soaked in the paraffin wax mixture for 38 minutes, and the superthermal conductivity composite phase change prepared The adsorption rate of the energy storage material is 79%, the energy storage rate can reach 210J / g, the thermal conductivity is higher than 16W / m.K, and the phase transition point is 130°C to 160°C.

Embodiment 3

[0044] The matrix is made of continuous porous metal aluminum foam, the solid-liquid phase change energy storage material is paraffin wax, the sealing material is graphite coating, the aluminum foam is soaked in the paraffin wax mixture for 45 minutes, and the superthermal conductivity composite phase change prepared The adsorption rate of the energy storage material is 80.5%, the energy storage rate can reach 325J / g, the thermal conductivity is higher than 16W / m.K, and the phase transition point is 130°C to 160°C.

[0045] At present, there are many theoretical studies on phase-change energy storage materials, but in actual production, there are few practical applications. After more than ten years of study, research and production practice, the applicant combined the investigation of phase-change energy storage materials technology in Europe, America and Japan. Cited, after repeated experiments, the superconducting thermal composite phase change energy storage material was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Phase transition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com