Active reliability analyzing and evaluating method for highly-reliable mechanical products

A technology for mechanical products, analysis and evaluation, applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

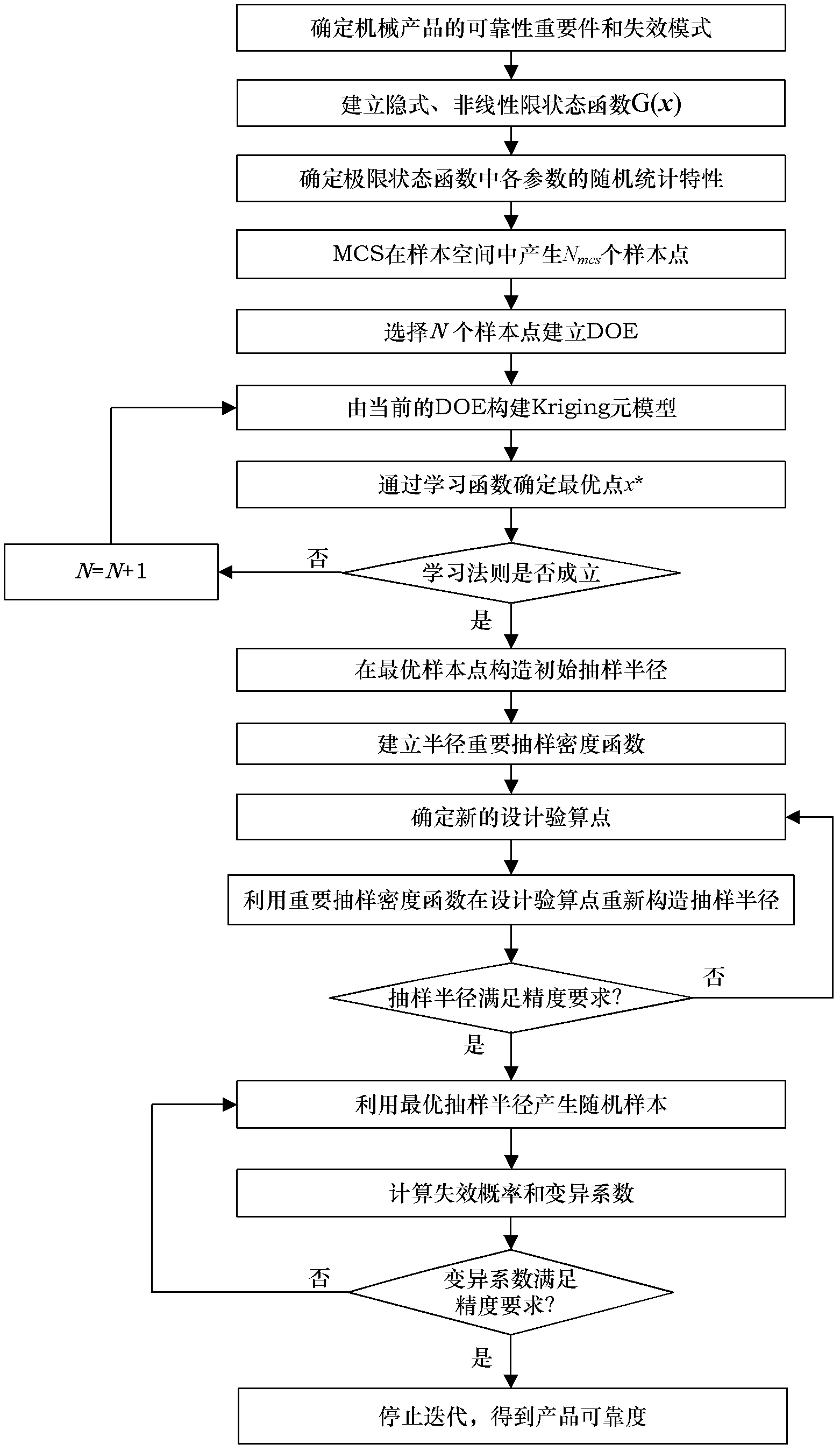

Method used

Image

Examples

Embodiment

[0084] The active reliability analysis method of the present invention will be introduced below through a specific engineering example of reliability analysis and evaluation of the fretting wear of the space structure lock.

[0085] 1) The failure mode and mechanism model of the fretting wear of the space structure lock.

[0086] During the docking and separation process of the two spacecraft, the active lock hook and the passive lock hook will have periodic small relative movements on the contact surface, which will cause wear particles on the contact surface, which are difficult to remove from the contact surface, and will be on the contact surface. Fretting wear occurs at the interface between the shackles. Such as Figure 4 Shown is the docking and unlocking process of the space structure lock.

[0087] The fretting movement form of the locking hook is relatively complicated, and its fretting form is tangential fretting. Many factors will affect fretting wear, such as re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com