Variable topology thyristor rectifier

A technology of thyristors and rectifiers, which is applied in the field of variable topology thyristor rectifiers, can solve problems such as low price-to-capacity ratio, large input voltage changes on the AC side, and harmonic pollution, so as to improve voltage levels and power levels, reduce pulsations, and reduce harmonics. The effect of wave pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

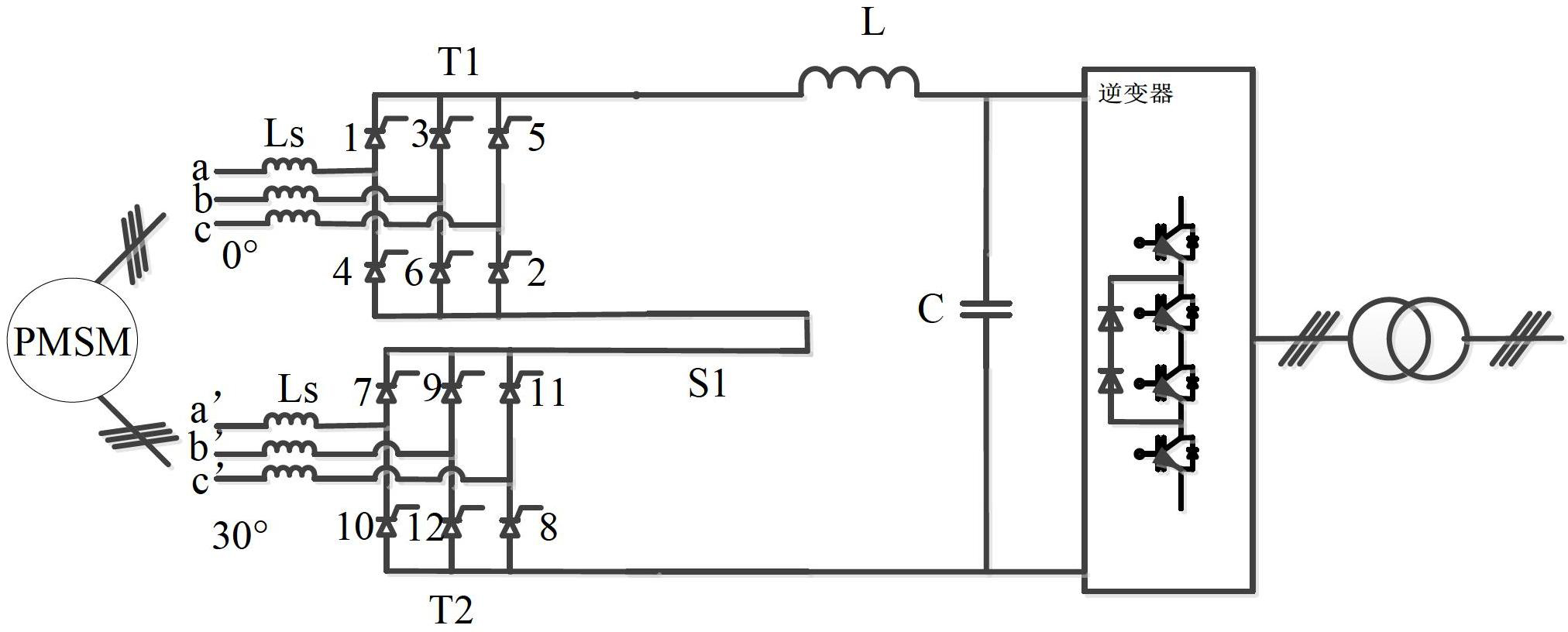

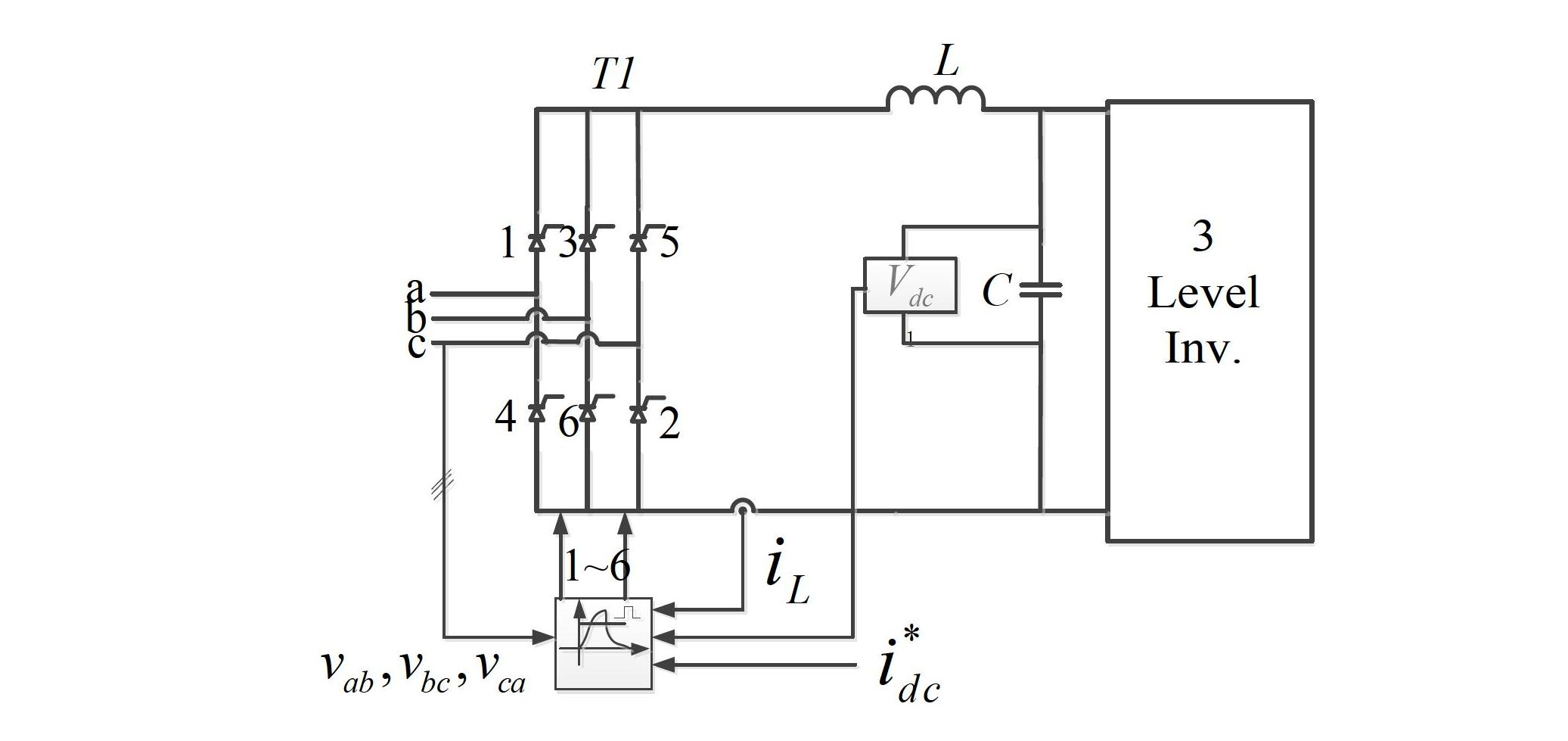

[0035] The wind power conversion device proposed by the present invention takes the variable topology thyristor rectifier as the front end, such as Figure 1-Figure 11 shown.

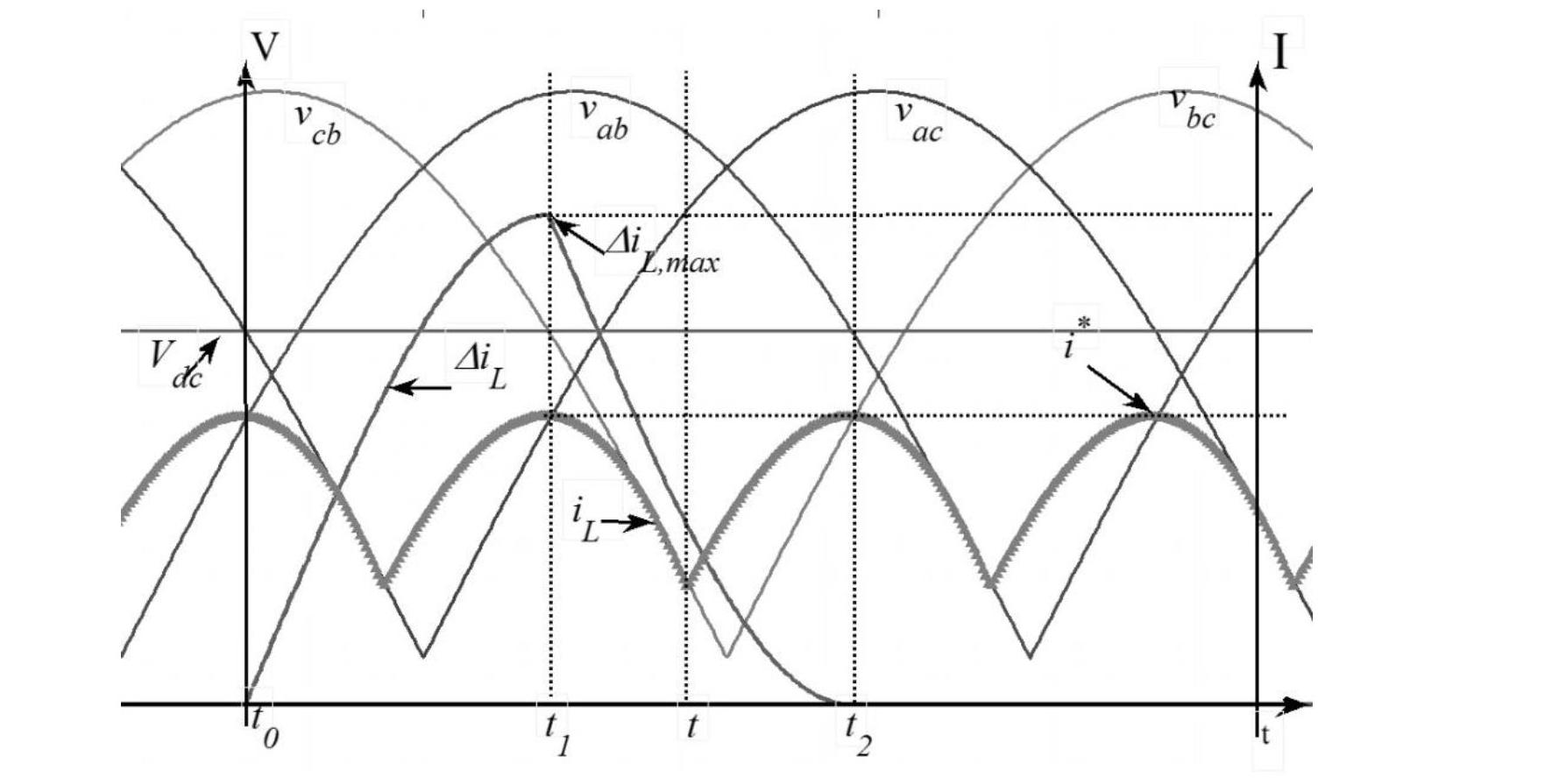

[0036] The variable topology thyristor rectifier includes two thyristor rectifier bridges T1, T2, the input ends of the two thyristor rectifier bridges T1, T2 can be respectively connected with a single-phase or three-phase isolated AC voltage source, and there is an electric current between the two isolated voltage sources. angle difference. The negative poles of the output terminals of the two thyristor rectifier bridges T1 are connected to the positive poles of the output terminals of T2, and both the positive poles of the output terminals of T1 and the negative poles of the output terminals of T2 are equipped with LC filters composed of inductors and capacitors.

[0037] Va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com