Module design for the components of a tank for storing a reducing agent

A reducing agent and bearing plate technology, which is applied to vehicle parts, mechanical equipment, engine components, etc., can solve the problems of increased risk of damage, etc., to increase the usable tank volume, improve the ice compressive strength, and improve the degree of freedom of innovation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

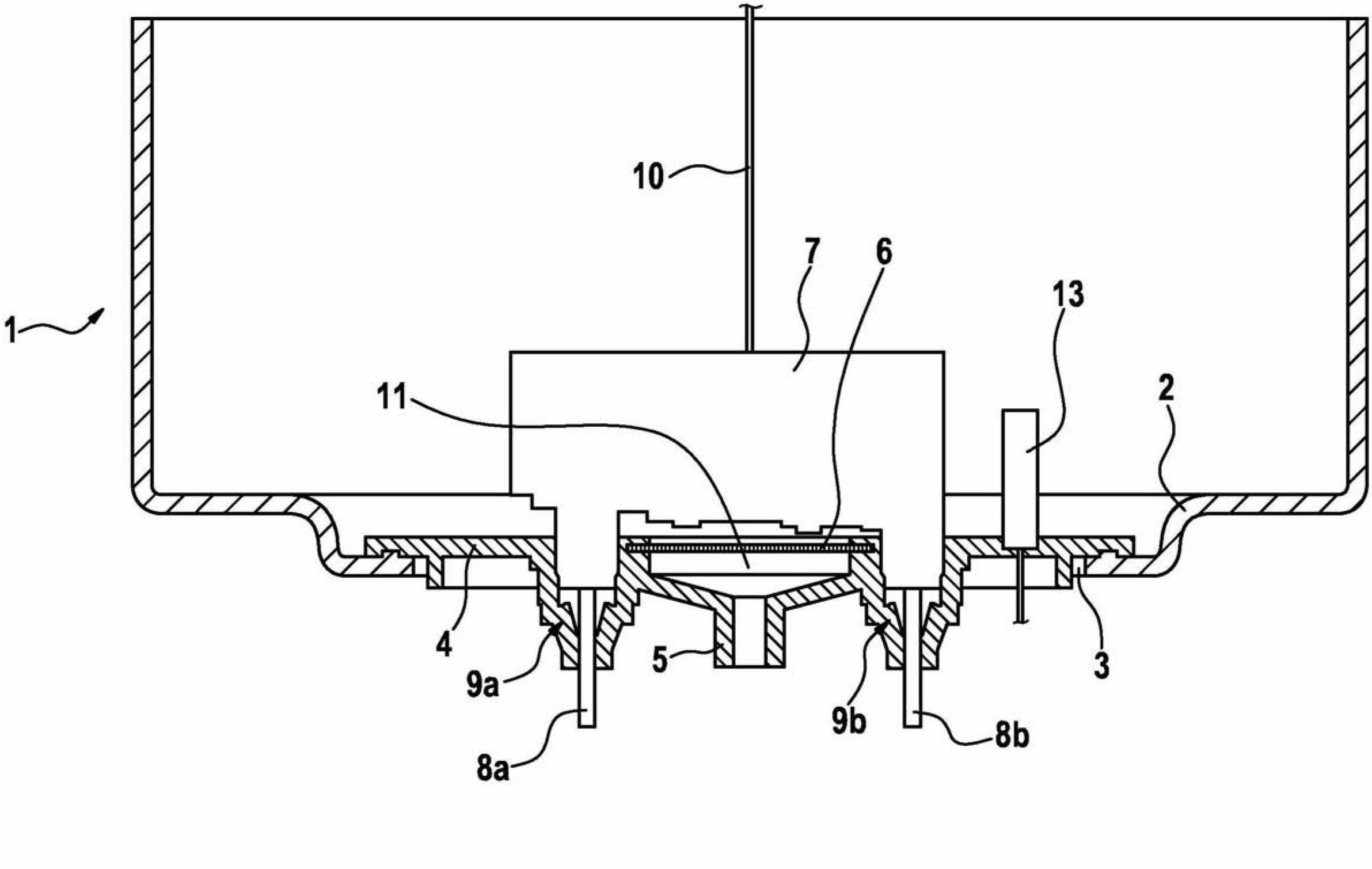

[0022] exist figure 1 The tank 1 shown in cross-section in FIG. 1 stores a reducing agent that reduces nitrogen oxides produced in the exhaust gas of an internal combustion engine into nitrogen and water. As a result, the reducing agent delivered from the tank via a supply module (not shown) is injected into the exhaust gas line of the internal combustion engine.

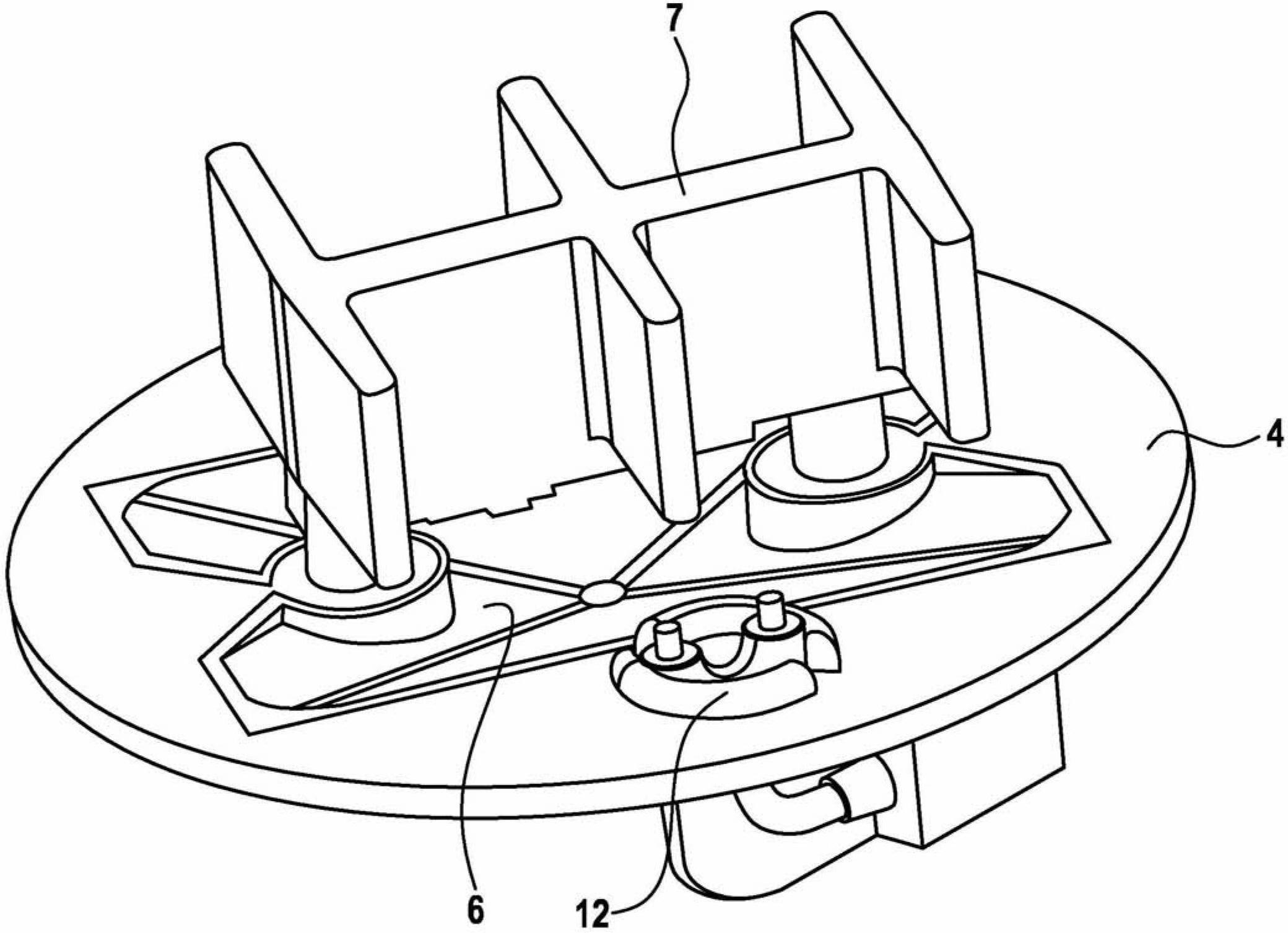

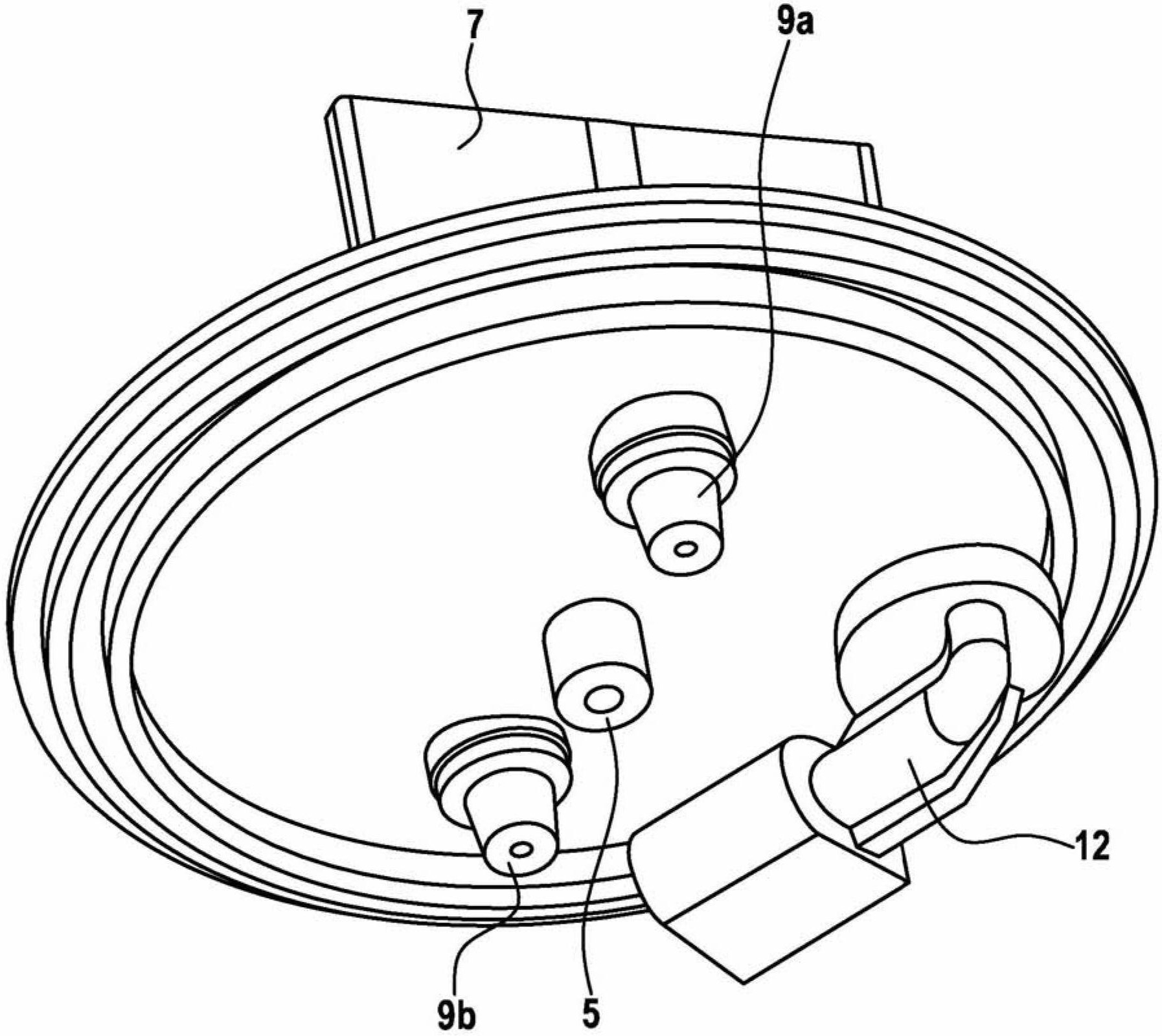

[0023] In the bottom area 2 , the tank 1 has an arbitrary geometric shape, in particular an annular opening 3 , which is closed tightly with a carrier plate 4 . Thus, the carrier plate 4 may comprise a seal, eg screwed, to the tank 1 . The carrier plate 4 has line ports 5 for line connections and / or return lines, wherein, if the line ports 5 are connected to a draw line, the line ports 5 are connected to a filter 6 in the form of a filtering screen. According to an embodiment, the line connection 5 is preferably configured as a single port for the suction line. However, the line port 5 can also be configured as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com