Feeding and compounding assembly for food stuffing

A composite component and stuffing technology, which is applied in food coating, food forming, food science, etc., can solve the problems of difficult flow control, unstable pressure, oil accumulation and other problems in the composite device, and prevent uneven inclusion around the surrounding , prolong service life, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

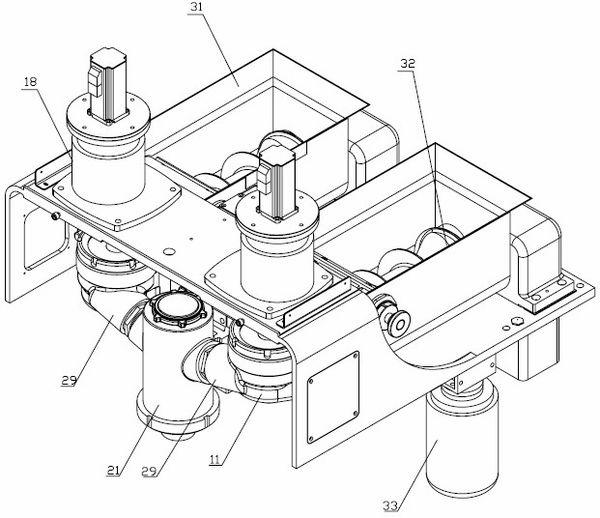

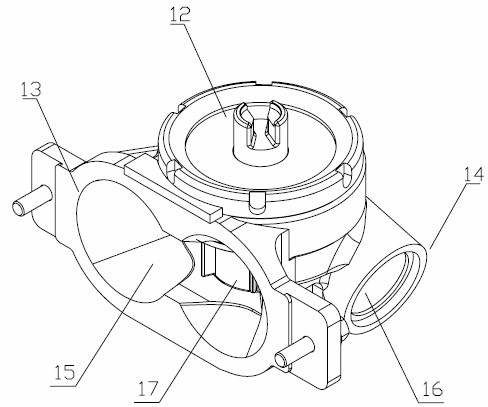

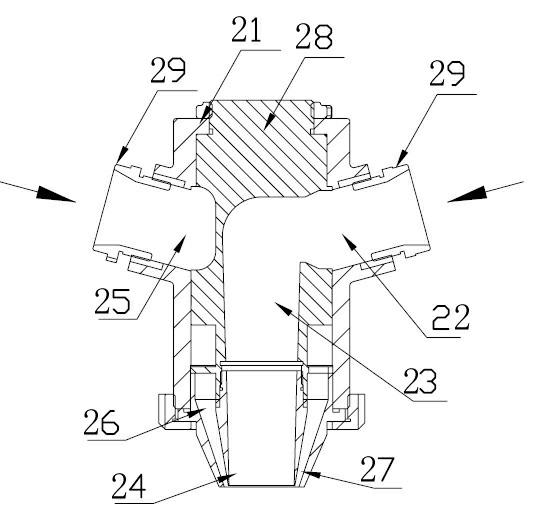

[0050] The food stuffing feeding compound assembly includes a feeding device and a compounding device, the feeding device is connected to the compounding device, and the compounding device includes a compounding head body 21 and a feed pump 11 communicated therewith, and the feed pump 11 is connected to the feeder The feeding device is connected; the feed pump 11 includes a pump body 12, a feed end 13 and a discharge end 14 on the pump body 12, and the horizontal section of the pump body 12 is circular, and the feed end 13 and the pump body 12 form a The feed channel 15 of the pump body 12, the pump body 12 discharge channel 16 is formed between the discharge end 14 and the pump body 12, the outer side of the pump body 12 feed channel 15 and the circular shape of the pump body 12 section Tangent, the outer side of the pump body 12 discharge channel 16 is tangent to the circular shape of the pump body 12 section; the discharge channel 16 is inclined downward relative to the bott...

Embodiment 2

[0058] The food stuffing feeding compound assembly includes a feeding device and a compounding device, the feeding device is connected to the compounding device, and the compounding device includes a compounding head body 21 and a feed pump 11 communicated therewith, and the feed pump 11 is connected to the feeder The feeding device is connected; the feed pump 11 includes a pump body 12, a feed end 13 and a discharge end 14 on the pump body 12, and the horizontal section of the pump body 12 is circular, and the feed end 13 and the pump body 12 form a The feed channel 15 of the pump body 12, the pump body 12 discharge channel 16 is formed between the discharge end 14 and the pump body 12, the outer side of the pump body 12 feed channel 15 and the circular shape of the pump body 12 section Tangent, the outer side of the pump body 12 discharge channel 16 is tangent to the circular shape of the pump body 12 section; the discharge channel 16 is inclined downward relative to the bott...

Embodiment 3

[0068] The food stuffing feeding compound assembly includes a feeding device and a compounding device, the feeding device is connected to the compounding device, and the compounding device includes a compounding head body 21 and a feed pump 11 communicated therewith, and the feed pump 11 is connected to the feeder The feeding device is connected; the feed pump 11 includes a pump body 12, a feed end 13 and a discharge end 14 on the pump body 12, and the horizontal section of the pump body 12 is circular, and the feed end 13 and the pump body 12 form a The feed channel 15 of the pump body 12, the pump body 12 discharge channel 16 is formed between the discharge end 14 and the pump body 12, the outer side of the pump body 12 feed channel 15 and the circular shape of the pump body 12 section Tangent, the outer side of the pump body 12 discharge channel 16 is tangent to the circular shape of the pump body 12 section; the discharge channel 16 is inclined downward relative to the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com