Low-sweetness energy slow-release peanut sugar and preparation method of low-sweetness energy slow-release peanut sugar

A peanut sugar and sweetness technology, applied in confectionery, confectionary industry, food science, etc., can solve the problems of high sweetness, high blood sugar, high calorie value, etc., and achieve the effect of not being prone to large fluctuations and reducing dental caries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

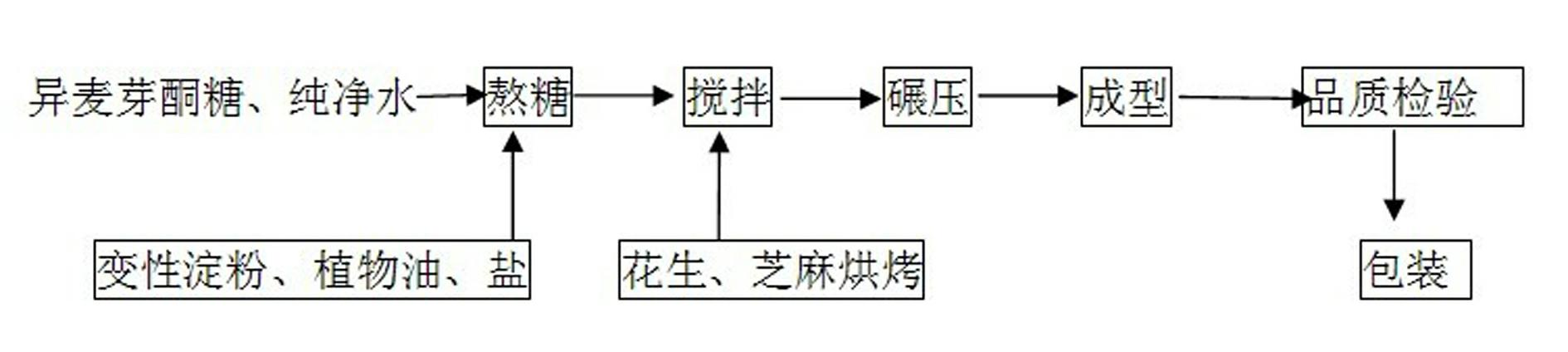

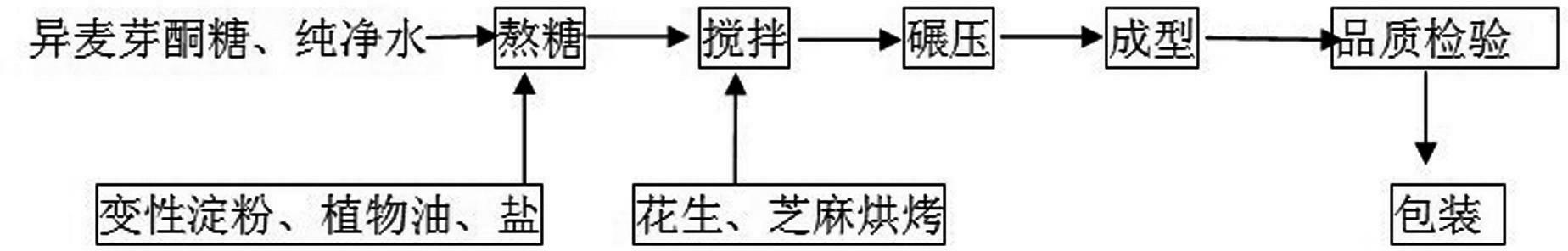

[0036] A preparation method of low-sweetness energy slow-release peanut candy, comprising the steps of:

[0037] (1) Weighing: Take 40 kg of isomaltulose, 20 kg of purified water, and 20 kg of high maltose syrup;

[0038] (2) Put the above materials into the pot and mix evenly, heat to boiling, and cook to 120°C;

[0039] (3) Add 0.5 kg of edible vegetable oil, 1 kg of modified starch, and 0.1 kg of salt, stir and dissolve, and continue to heat and boil;

[0040] (4) When the syrup is boiled to a temperature above 148°C, stop heating;

[0041] (5) Pour in 80 kg of peeled peanut kernels and 4 kg of sesame seeds, and stir fry evenly;

[0042] (6) Pour it into the mold while it is hot, roll it firmly with a wooden stick, and cool it naturally;

[0043] (7) After cooling, cut into shape, pack and store.

Embodiment 2

[0045] A preparation method of low-sweetness energy slow-release peanut candy, comprising the steps of:

[0046] (1) Weighing: Take 30 kg of isomaltulose, 18 kg of purified water, 1 kg of sucrose, and 30 kg of high maltose syrup;

[0047] (2) Put the above materials into the pot and mix evenly, heat to boiling, and cook to 120°C;

[0048] (3) Add 1.5 kg of edible vegetable oil, 2 kg of modified starch, and 0.1 kg of salt, stir and dissolve, and continue to heat and boil;

[0049] (4) When the syrup is boiled to a temperature above 148°C, stop heating;

[0050] (5) Pour in 70 kg of peeled peanut kernels and 2 kg of sesame seeds, and stir fry quickly and evenly;

[0051] (6) Pour it into the mold while it is hot, roll it firmly with a wooden stick, and cool it naturally;

[0052] (7) After cooling, cut into shape, pack and store.

[0053] The modified starch described in the above embodiments is one of acetate modified starch, oxidized starch and phosphated modified starch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com