Composite sweetener

A compound sweetener and sodium cyclamate technology, applied in the field of sweeteners, can solve the problem of not being able to achieve a good taste of sucrose, and achieve the effect of solving obesity and reducing cost pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

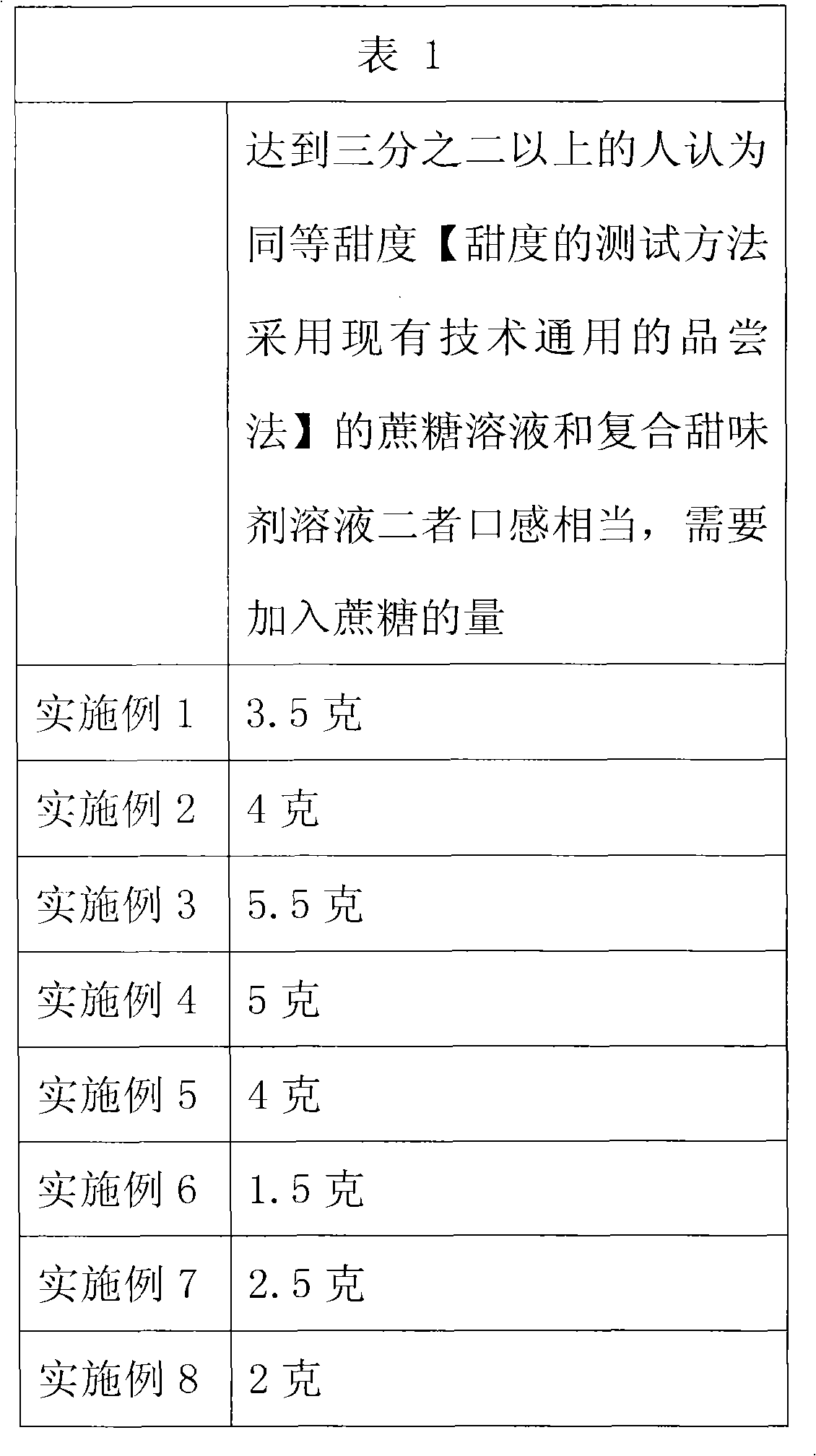

Examples

Embodiment 1

[0015] The compound sweetener of this embodiment is composed of the following materials in parts by weight: 98 kg of stevioside, 30 kg of cyclamate, 20 kg of sodium saccharin, 5 kg of dextrin and 0.5 kg of essence. The stevioside contains rebaudioside A, rebaudioside C, stevioside, dulcoside A and steviobioside, and the total mass fraction of the five in the stevioside is 75%. The mass fraction of rebaudioside C is 5%, and the mass fraction of stevioside is 65%.

Embodiment 2

[0017] The compound sweetener of this embodiment is composed of the following materials in parts by weight: 75 kg of stevioside, 20 kg of cyclamate, 25 kg of sodium saccharin, 10 kg of dextrin and 1 kg of essence. Stevioside contains rebaudioside A, rebaudioside C, stevioside, dulcoside A and steviobioside, and the total mass fraction of the five in stevioside is 98%. The mass fraction of rebaudioside C is 10%, and the mass fraction of stevioside is 80%.

Embodiment 3

[0019] The compound sweetener of this embodiment is composed of the following materials in parts by weight: 75 kg of stevioside, 28 kg of cyclamate, 25 kg of sodium saccharin, 10 kg of dextrin and 1 kg of essence. Stevioside contains rebaudioside A, rebaudioside C, stevioside, dulcoside A and steviobioside, and the total mass fraction of the five in stevioside is 76%. The mass fraction of rebaudioside C is 6%, and the mass fraction of stevioside is 67%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com