Method for preparing cigarette dual-fiber hybrid filter tip by utilizing soybean fibers

A soybean fiber and fiber technology, which is applied in the direction of e-liquid filter, application, tobacco, etc., can solve the problem that it cannot be used alone, and achieve the effect of keeping the quality of smoking food unchanged, the diameter is uniform and the performance index is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

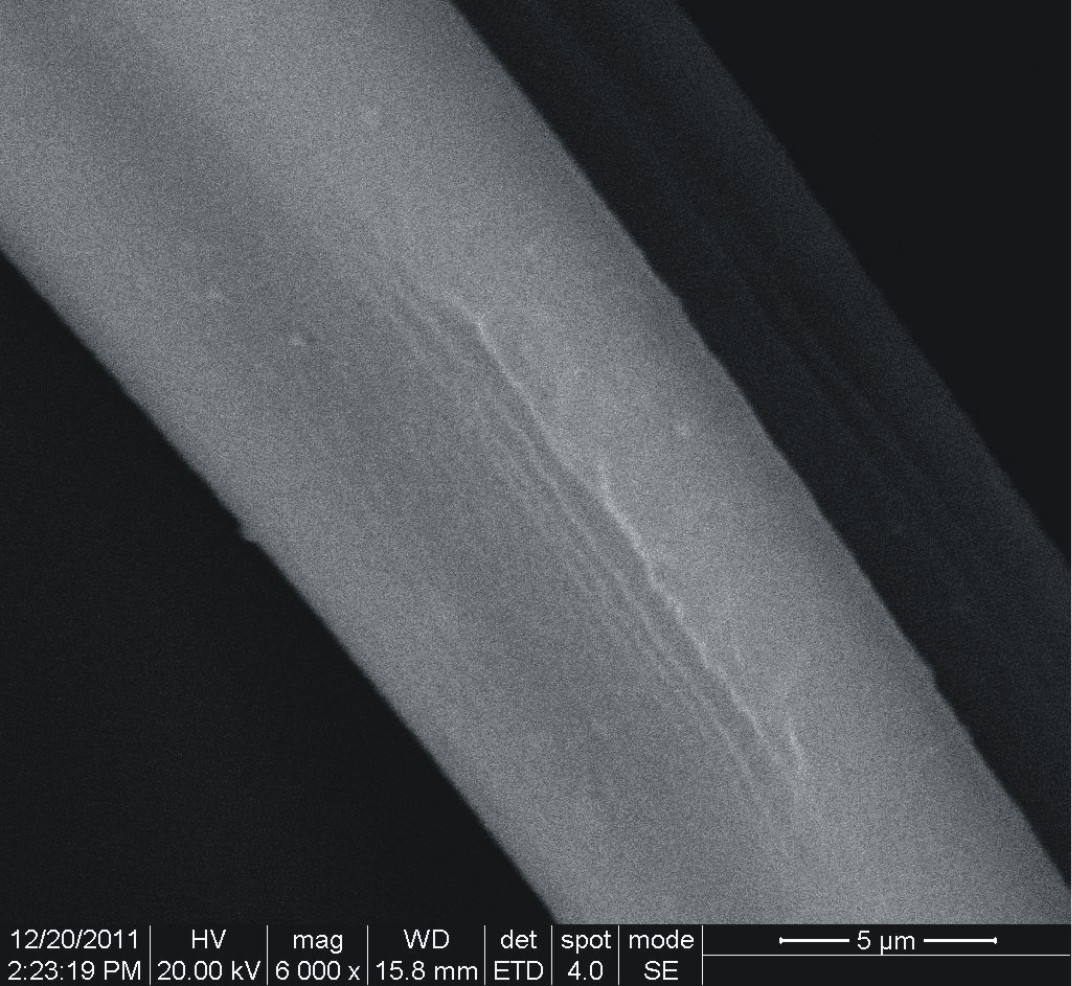

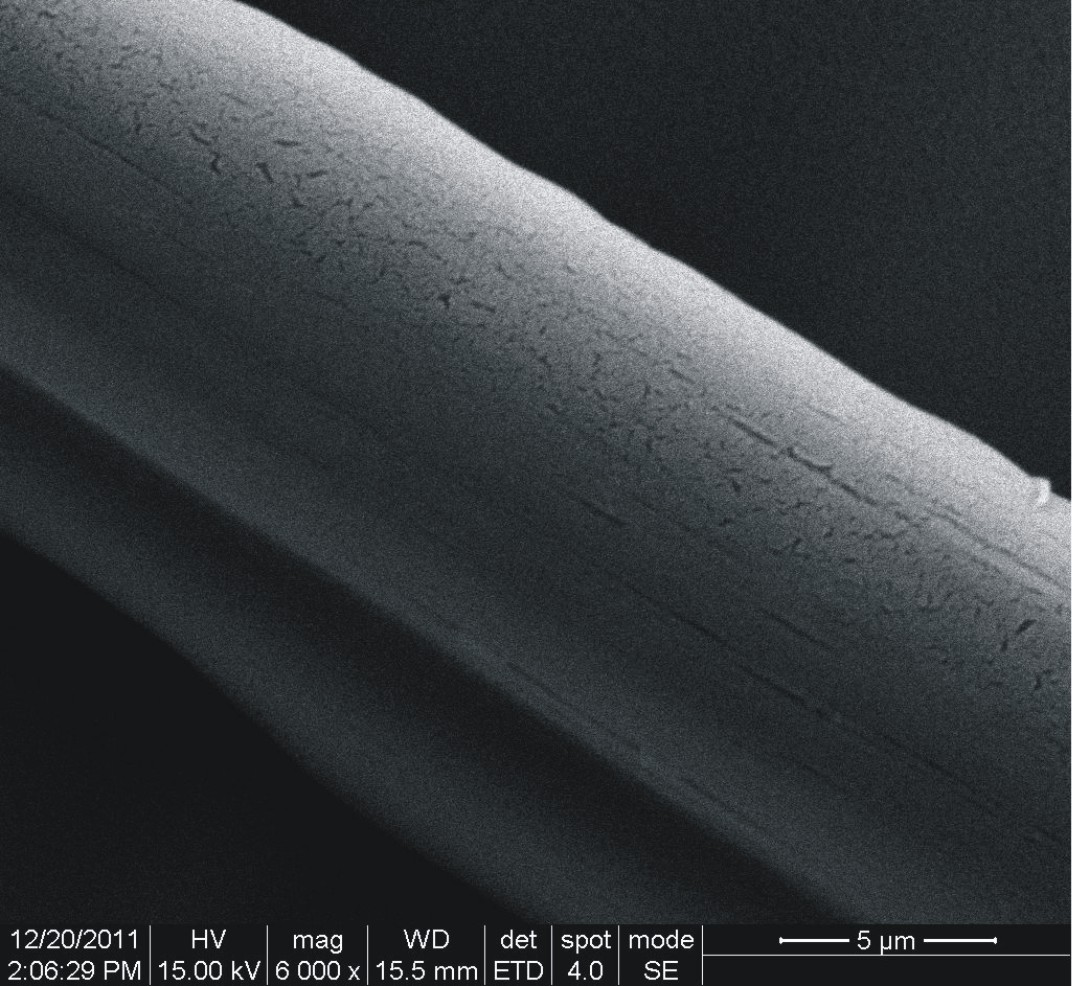

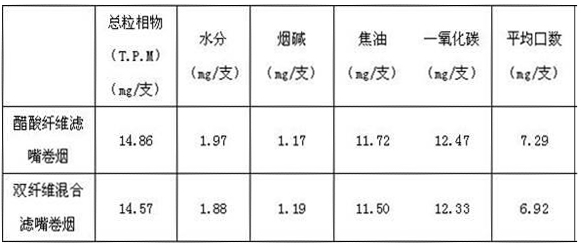

[0020] A dual-fiber hybrid filter was prepared by using soybean raw silk fiber and acetate fiber for tobacco. Firstly, straighten 5kg of soybean raw silk fibers in the length direction and stretch them evenly in the width direction to form a thin layer with a width of 25 cm. Humidify with a little atomization or place in a humidifying box with a relative humidity of 90% and a temperature of 40°C to make it dry. Wetting the surface reduces curling and discharge caused by static electricity. Leave it for 15 minutes to allow the surface moisture to evaporate naturally. Stretch the cellulose acetate bundle into a thin layer, so that the width of the thin layer is the same as the stretched width of the soybean fiber; overlap and mix the wetted soybean fiber layer and the acetate fiber layer together to form a bundle, and then carry out 5 times Mixed stretching makes the two fibers mix evenly to form a mixed fiber bundle. Stretch the mixed fiber bundle transversely to 40cm to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com