Tank-tank type liquid distributor

A liquid distributor and trough-type technology, which is applied in the field of trough-type liquid distributors, can solve the problems of uneven liquid distribution, uneven liquid drop point, uneven hole distribution, etc., and achieve the goal of improving mass transfer efficiency and uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

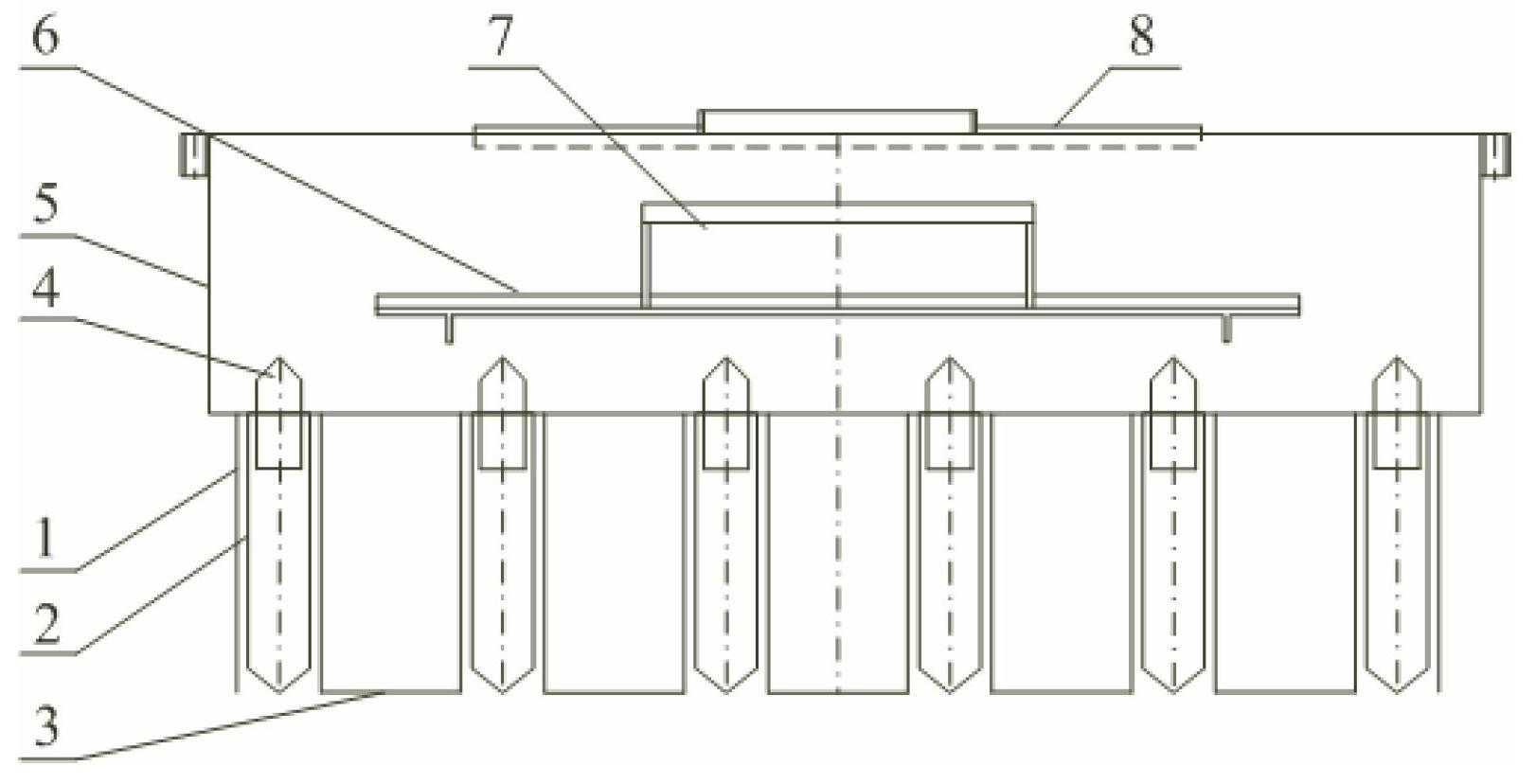

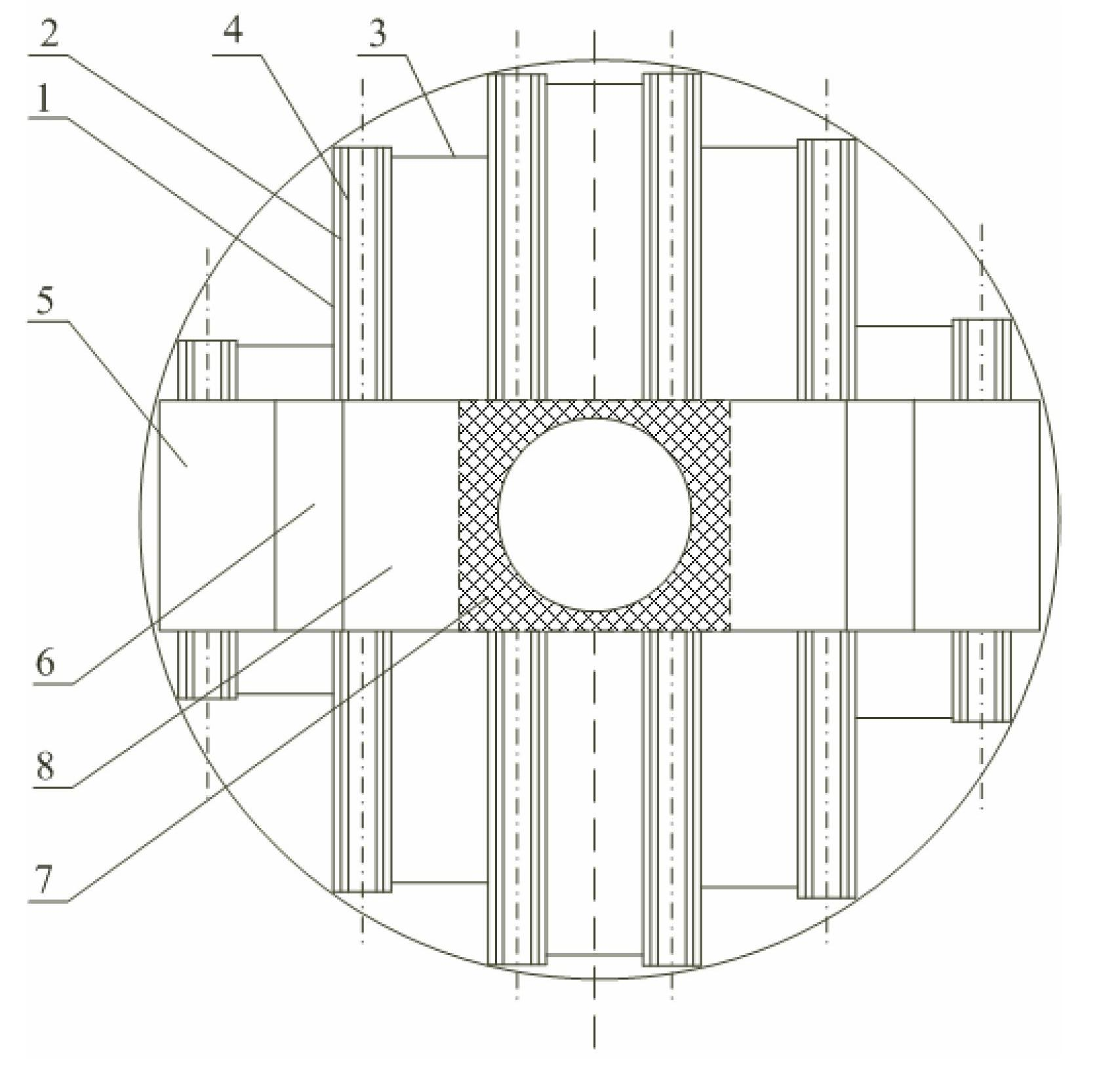

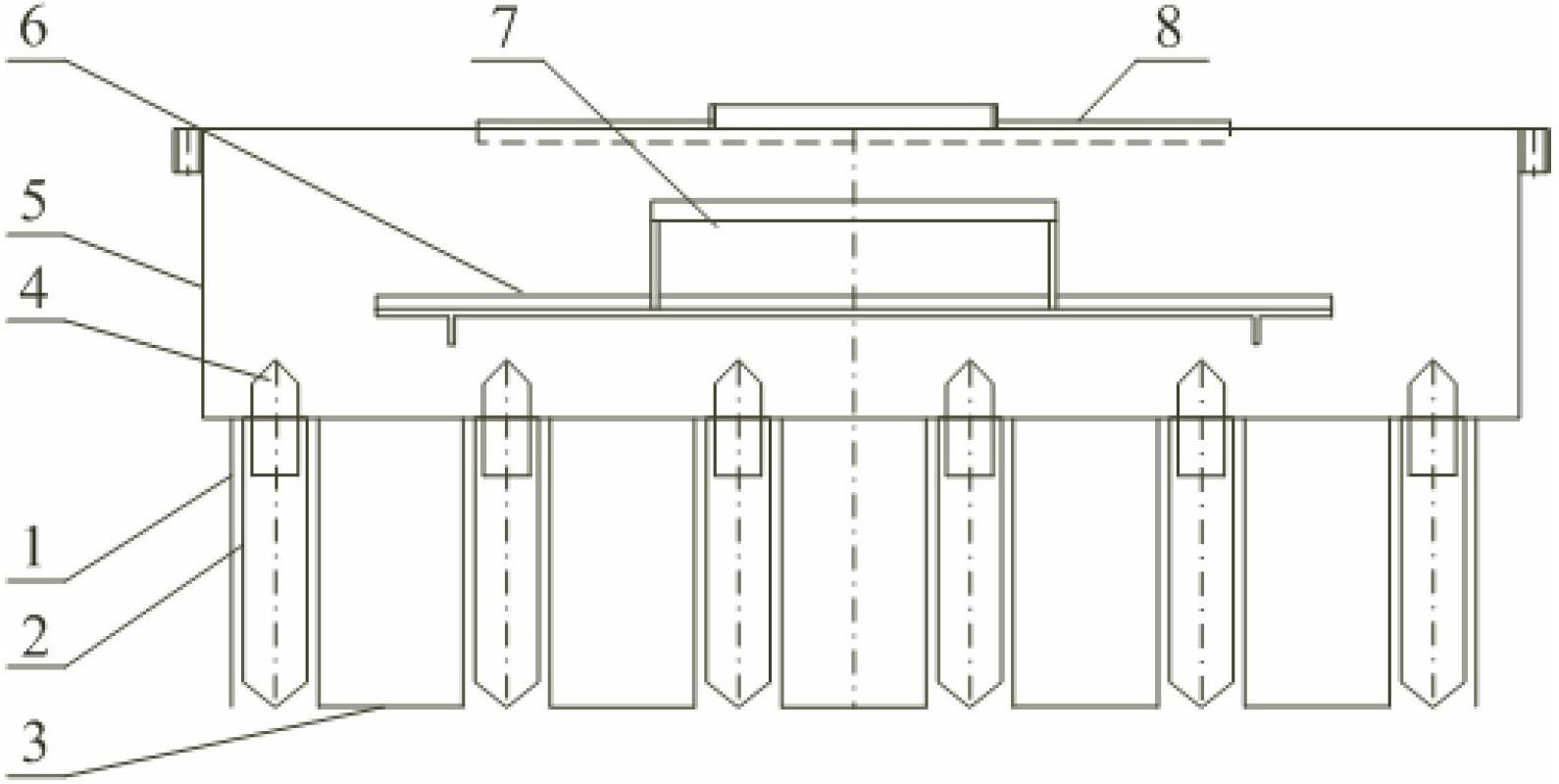

[0021] Embodiment 1: as figure 1 As shown, one embodiment of the present invention is to make a trough-type liquid distributor, comprising a primary groove and 8 secondary grooves, the width of the primary groove is 250mm, the width of the secondary groove is 200mm, and its height Both are 295mm, the average diameter of the small holes distributed in the secondary groove is 3.5mm, the average distance between the centers of two adjacent distributed small holes is 7.1mm, the average diameter of the larger distributed holes on the side of the secondary groove is 20mm, and the hole spacing is 30mm. In the process of methanol purification and refining, the tank-type liquid distributor and BH-type high-efficiency packing technology are used to promote the uniform distribution of liquid in the packed tower, and the packed tower has high efficiency. Compared with the ordinary orifice liquid distributor under the same conditions, the reflux ratio at the top of the tower is reduced fro...

Embodiment 2

[0022] Embodiment 2: as figure 1 As shown, one embodiment of the present invention is to make a trough type liquid distributor, comprising a primary groove and 6 secondary grooves, the width of the primary groove is 500mm, the width of the secondary groove is 150mm, and its height Both are 250mm, the average diameter of the small holes distributed in the secondary groove is 3.5mm, the average distance between the centers of two adjacent distributed small holes is 7.1mm, the average diameter of the larger distributed holes on the side of the secondary groove is 20mm, and the hole spacing is 30mm. In the methyl acetate recovery tower, the trough-type liquid distributor and BH-type high-efficiency packing technology are used. Compared with the ordinary orifice-type liquid distributor under the same conditions, the content of methyl acetate at the top of the tower rises from 78% to 82%. , the content of methyl acetate at the bottom of the tower dropped from 0.28% to 0.01%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com