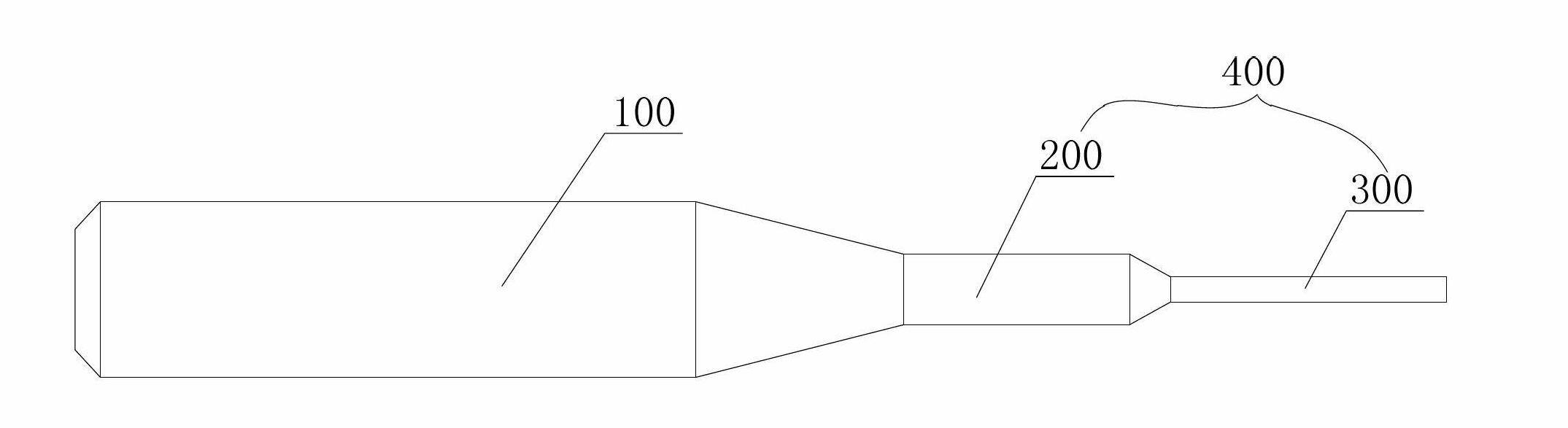

Miniature drilling bit and machining method thereof

A micro-drill and drill technology, which is applied in metal processing equipment, drill repairs, drilling tool accessories, etc., can solve the problems of excessive deflection of the drill, the performance of the hole of the drill, and the influence of the accuracy of the hole. The effect of hole position accuracy, increasing rigidity strength, and reducing the magnitude of bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

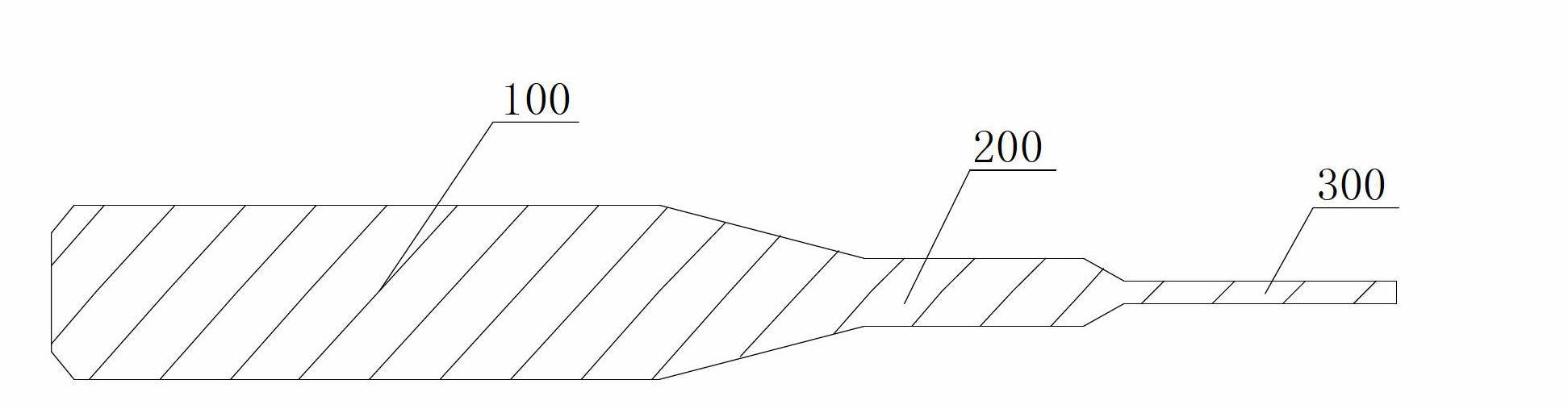

Embodiment 1

[0040] Such as Figure 7 As shown, there is only one enlarged part of the transition platform 200, and its cylindrical surface is a conical surface, so that the cylinder of the transition platform 200 is thicker, and the strength of the transition platform 200 is further improved. One end of the enlarged portion is integrally formed with the drill shank 100 , and the other end is connected with a cylindrical portion 220 with a constant diameter. The cylindrical surface of the guide surface 210 is preferably a conical surface, which can prevent the transition part from accumulating debris; Other shapes such as inner arc surface and outer arc surface are adopted.

[0041] The cylindrical surface of the enlarged part adopts a conical surface, the processing is relatively simple, and the processing cost is low; of course, shapes such as inner arc surface and outer arc surface can also be used. The use of the inner arc surface can increase the vacuum space of the micro-drill; it ...

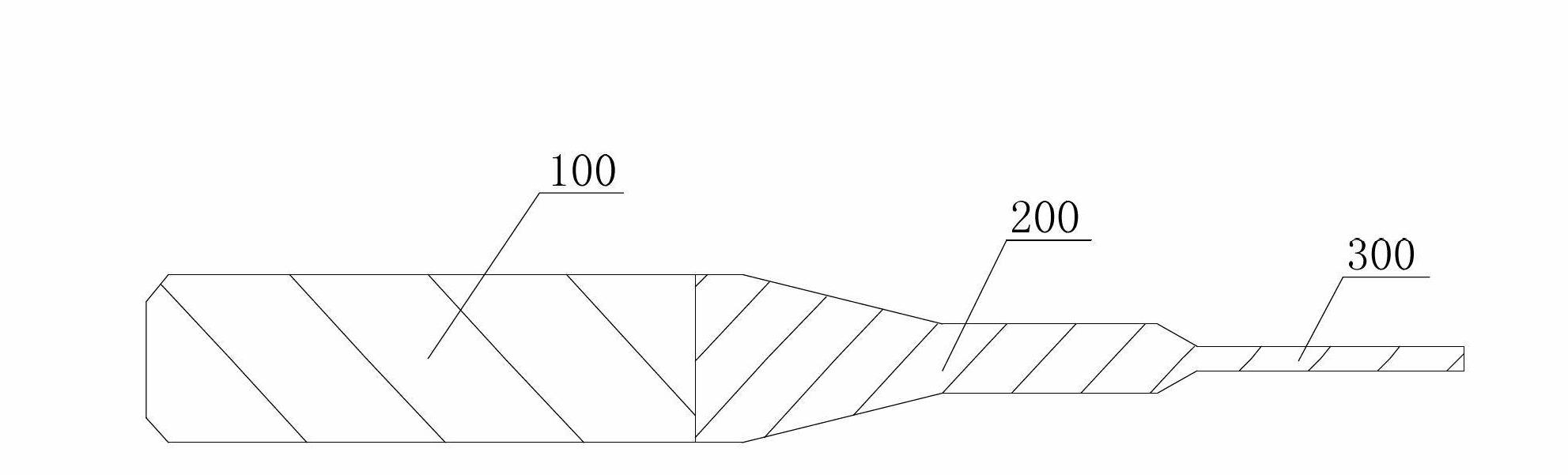

Embodiment 2

[0044] Such as Figure 8 As shown, the transition table 200 includes a guide surface 210 connected with the drill pin 300, a cylindrical part 220 with a constant diameter connected with the guide surface 210, a first enlarged part 230 connected with the cylindrical part 220, and a cylindrical part 230 connected with the drill shank 100. The second enlarged portion 240 is fixedly connected to the first enlarged portion 230 and the second enlarged portion 240 , and the cylindrical surface of the first enlarged portion 230 is a conical surface. Of course, the cylindrical portion 220 may also be omitted, that is, the first enlarged portion 230 is connected to the guide portion 210 . The processing of the conical surface is relatively simple and the processing cost is low. The guide surface 210 and the second enlarged portion 240 adopt a conical surface transition structure, which facilitates the transition between two parts with different diameters (between the drill shank 100 an...

Embodiment 3

[0047] Such as Figure 9 As shown, the transition table 200 includes a guide surface 210 connected with the drill pin 300, a cylindrical part 220 with a constant diameter connected with the guide surface 210, a first enlarged part 230 connected with the cylindrical part 220, and a cylindrical part 230 connected with the drill shank 100. The second enlarged portion 240 is fixedly connected to the first enlarged portion 230 and the second enlarged portion 240 , and the cylindrical surface of the first enlarged portion 230 is an inner arc surface concave inward. Of course, the cylindrical portion 220 may also be omitted, that is, the first enlarged portion 230 is connected to the guide portion 210 . The inner arc surface can increase the vacuum space of the micro-drill, which is beneficial to chip removal during processing. The guide surface 210 and the second enlarged portion 240 adopt a conical surface transition structure, which facilitates the transition between two parts wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com