A kind of intelligent guide rail forming machine and its control method

A control method and molding machine technology, applied in the direction of manufacturing tools, signal transmission systems, shearing machine accessories, etc., can solve problems such as difficulty in reflecting product price advantages, high product cost pressure, and increased product cost, and achieve simple structure Reasonable, high production efficiency, and the effect of reducing resource costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

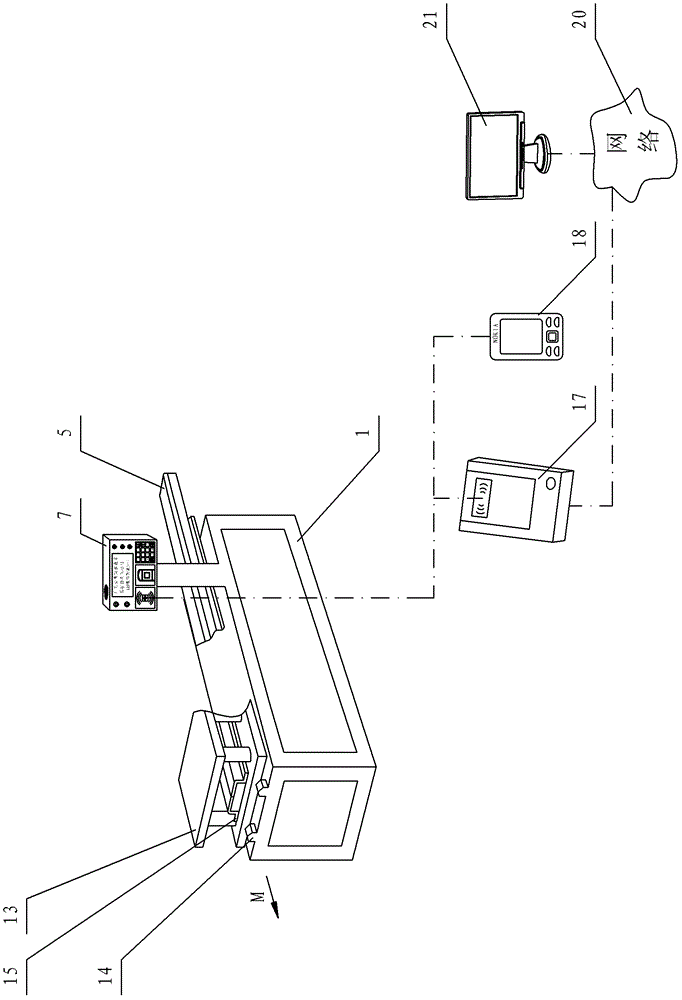

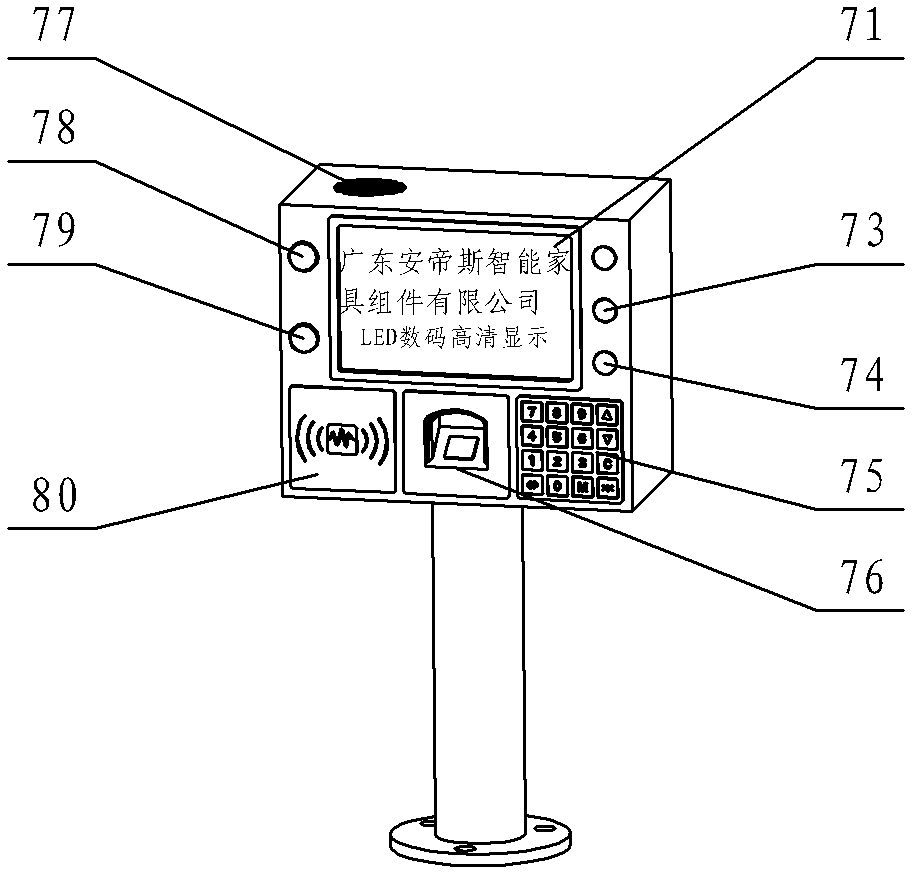

[0020] see Figure 1-Figure 2 , the intelligent rail forming machine includes a frame 1 and a main controller 7, a workbench is arranged on the frame 1, and a guide mechanism 14 for conveying workpieces 5 is arranged on the workbench; a microwave induction area is arranged on the main controller 7 80, the main controller 7 is used in conjunction with the remote microwave sensor 17, the computer 21, and the mobile phone 18, wherein the microwave sensing area 80 is used to receive microwave signals transmitted from the remote microwave sensor 17, and the mobile phone 18 sends control signals to the remote microwave The sensor 17 and the computer 21 send control signals to the remote microwave sensor 17 through the network 20 .

[0021] The main controller 7 is provided with a display screen 71 , a remote control indicator light 73 , a password operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com