Electric power piston driving type electric vehicle and working method thereof

A piston-driven, electric vehicle technology, used in electric vehicles, electric braking systems, motor vehicles, etc., can solve the problems of inability to change the current direction instantaneously, high cost, and difficult to achieve, achieve good continuity and stability, avoid Delayed, reliable start-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

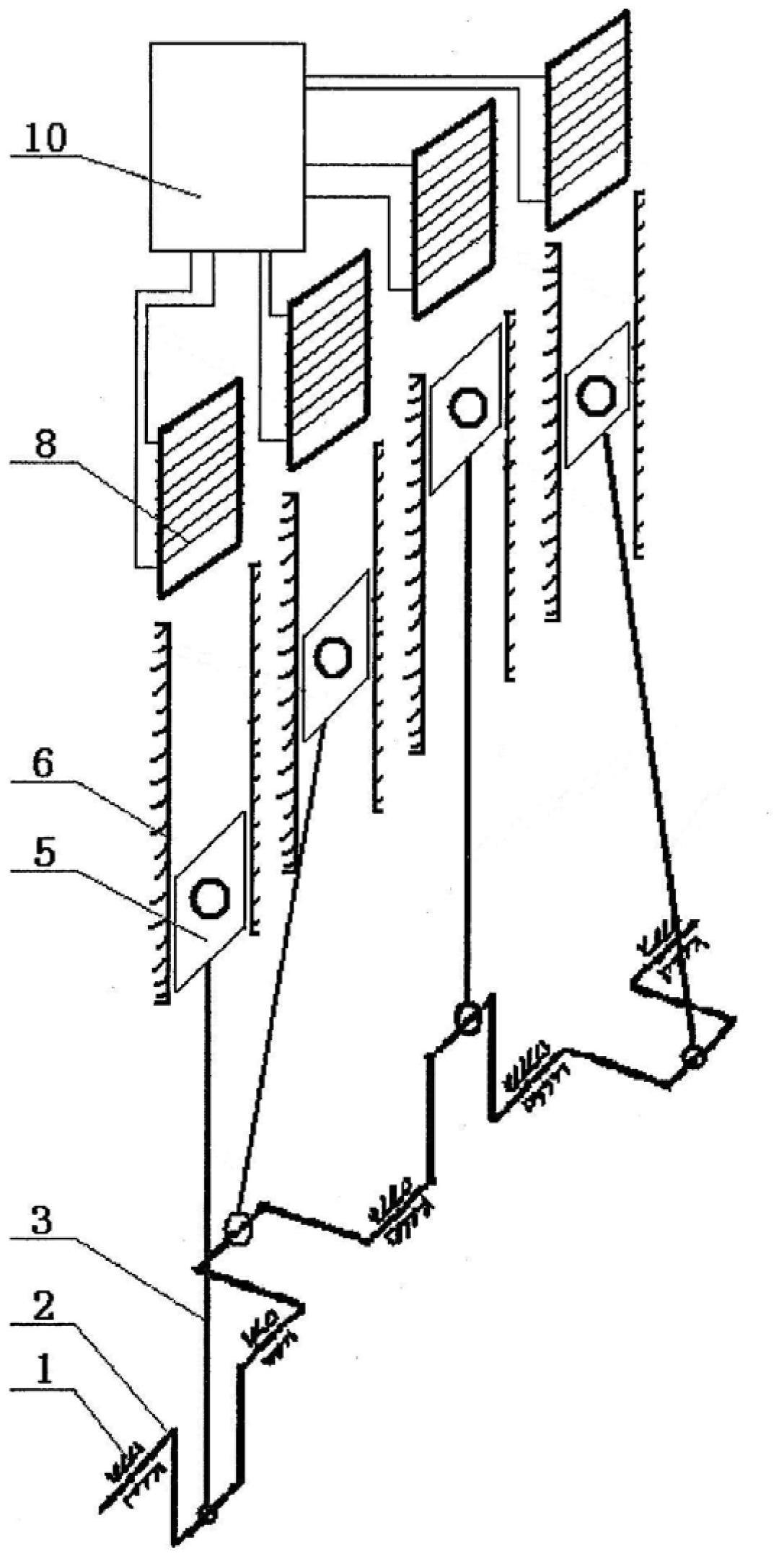

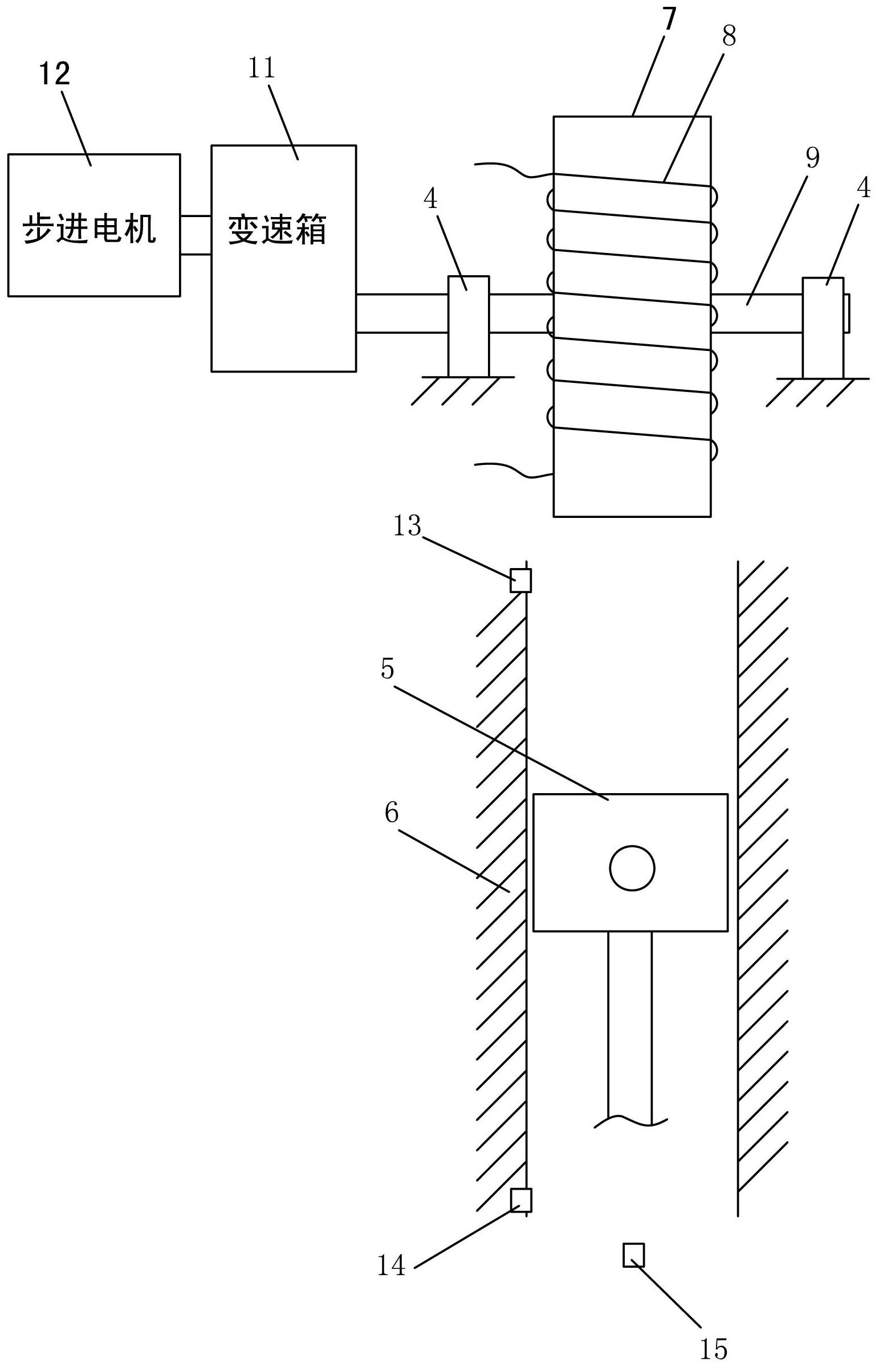

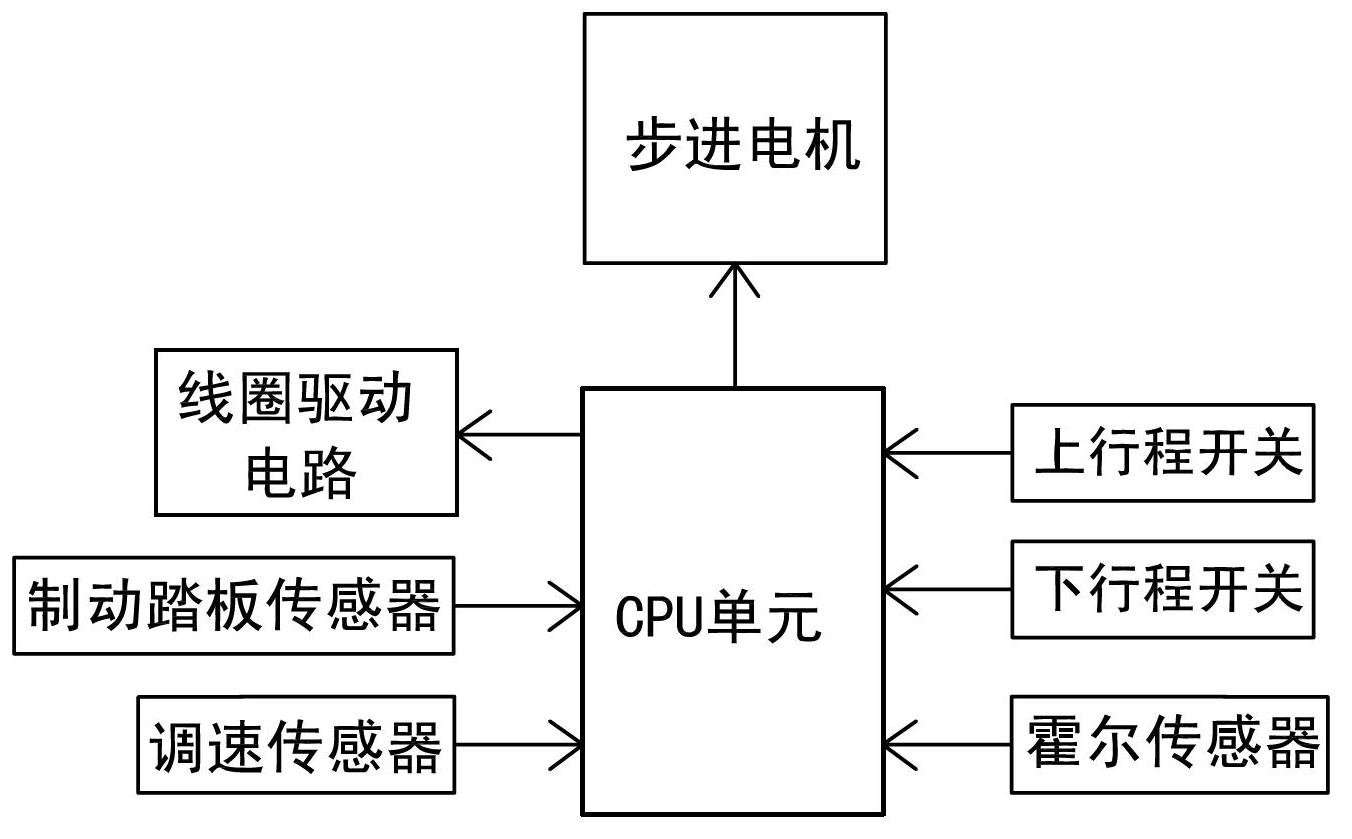

[0020] See Figure 1-3, the electric piston-driven electric vehicle suitable for electric braking in this embodiment includes: a braking system, an electric piston motor 20, a flywheel connected to the crankshaft in the electric piston motor 20, and a clutch 21 arranged on the flywheel , the gearbox 22 that links to each other with the output shaft of clutch 21, the vehicle transmission system that is connected with the output shaft transmission of gearbox 22; The ring gear on the outer edge of the flywheel meshes with the driving gear of a starting system. The starting system adopts the starting system in the prior art which is matched with the existing gasoline engine.

[0021] The vehicle transmission system includes: a drive shaft 24 connected to the output shaft of the gearbox 22 via a universal joint 23, a differential 27 connected to the drive shaft 24 via another universal joint, and a differential 27 connected to the differential 27. The connected wheels are driven v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com