Device for eliminating overvoltage of passing neutral section through silicon carbide fiber rope

A technology of silicon carbide fiber and over-phase separation, which is applied in the direction of power lines, overhead lines, transportation and packaging, etc., can solve problems such as interruption of power supply and transportation, discharge of roof protection gap, tripping of traction substation, etc., to reduce installation costs , safe and reliable operation strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with specific embodiments.

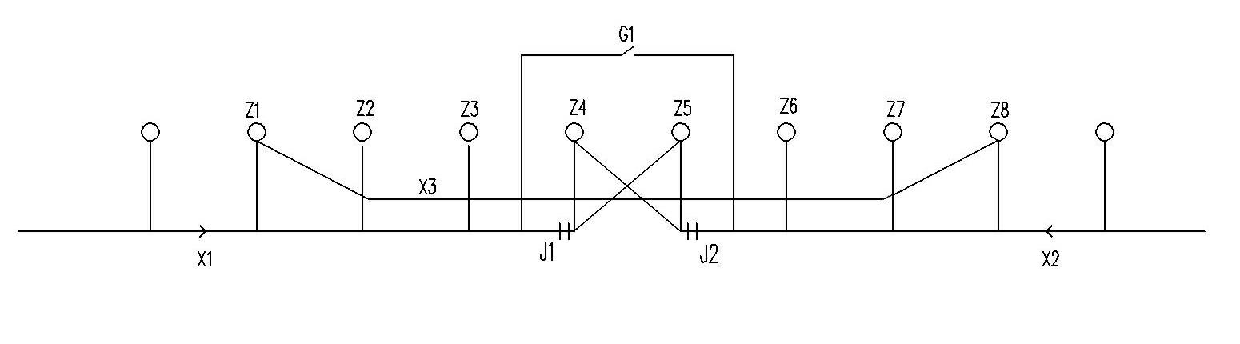

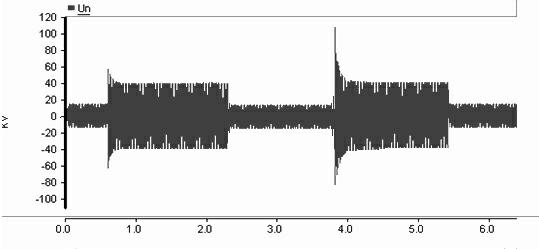

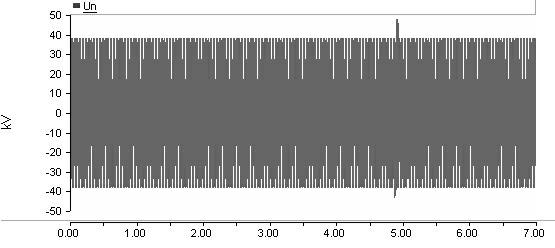

[0021] The neutral section of the catenary generally uses the same copper alloy wire as the catenary power supply arm. The neutral conductor of the articulated electrical phase separation, on the one hand, is only 400~500 mm away from the left and right adjacent catenary conductors. The small distance electrostatic induction causes the induced voltage on the neutral conductor (test shows that the neutral conductor The induced voltage is as high as 10 kV~15 kV); on the other hand, the height of the neutral conductor to the steel rail is about 6 m. Because it is a suspended independent metal conductor, it has a capacitance to the ground and stores electromagnetic energy. When entering and driving out of the split phase, the capacitor is forced to charge and discharge, resulting in electromagnetic oscillation overvoltage. figure 2 It is the simulation waveform of the overvolta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com