Method for remedying filamentous expanded aerobic granular sludge

An aerobic granular sludge and granular sludge technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as swelling, filamentous bacteria growth, etc. The effect of smooth, regular shape, good settling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

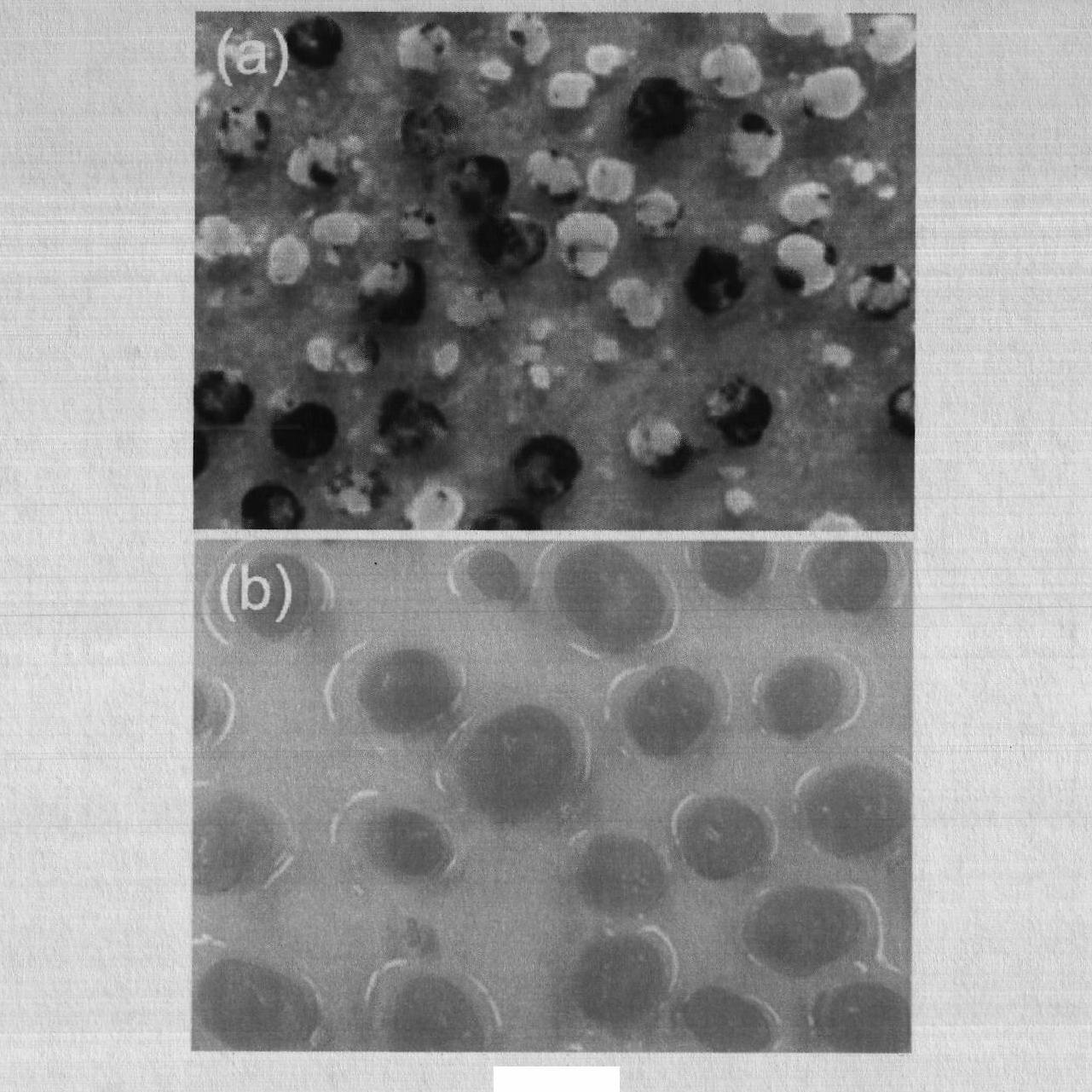

[0018] (1) Granular sludge to be repaired: the influent COD is 500mg / L, and the organic load is 1.5g COD / m 3 ·d, C:N:P=100:5:1 glucose artificial wastewater culture, the average particle diameter is 3mm, SVI is 70ml / g, biomass is about 6g SS / L. The presence of black filamentous bacteria on the surface of the particles can be observed with the naked eye, and the filamentous swelling of granular sludge such as figure 1 as shown in a.

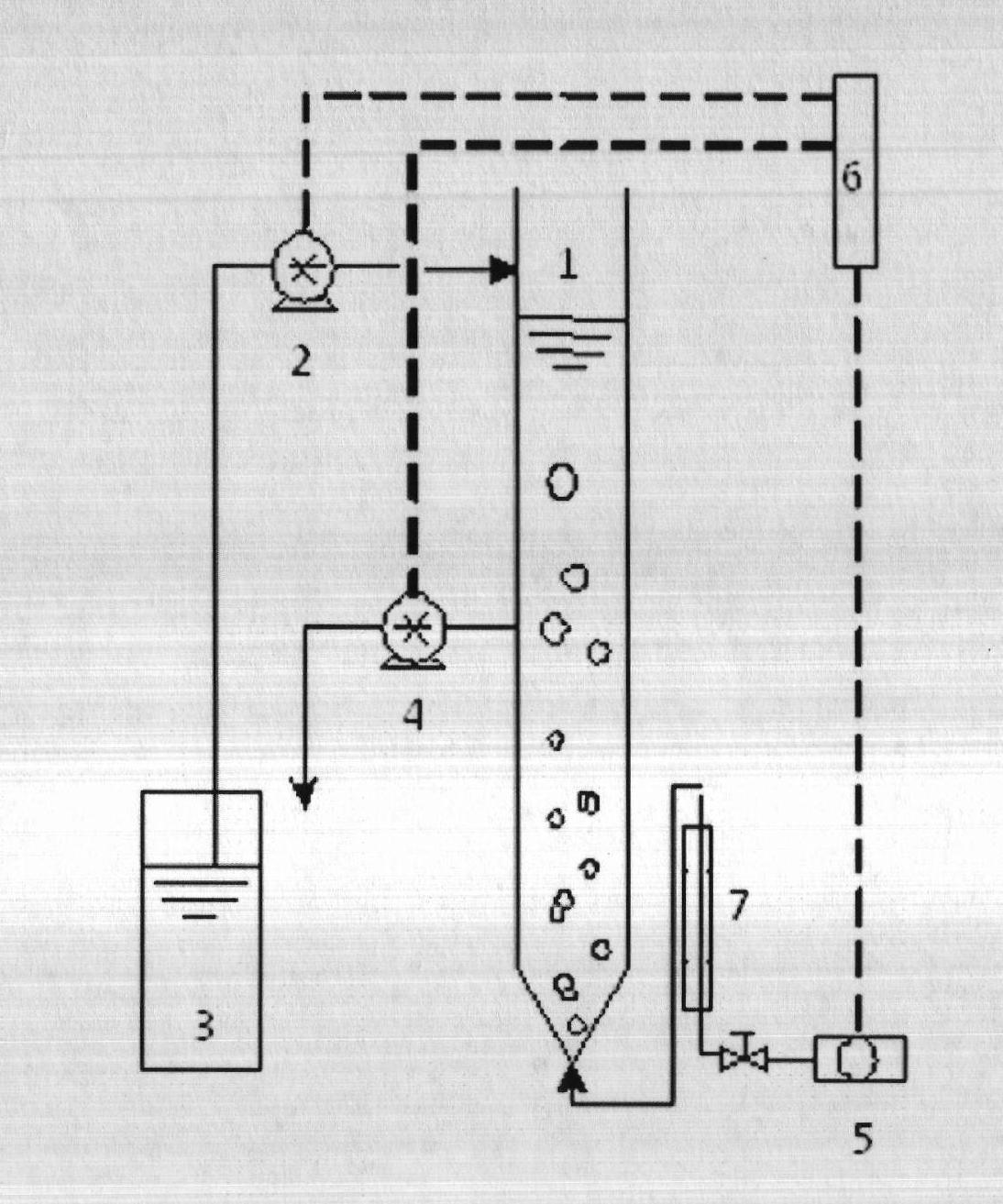

[0019] (2) Bioreactor: The reactor is made of plexiglass, with a height of 80 cm, an inner diameter of 6 cm, and an effective volume of 2.4 L. The air enters the reactor through the microporous aeration head installed at the bottom of the reactor by the air pump, and the airflow formed provides the oxygen required for the growth of microorganisms and the shear force that is beneficial to the separation of filamentous bacteria on the surface of the particles. The aeration volume in the whole repair process is about 7L / min. The water outlet is lo...

Embodiment 2

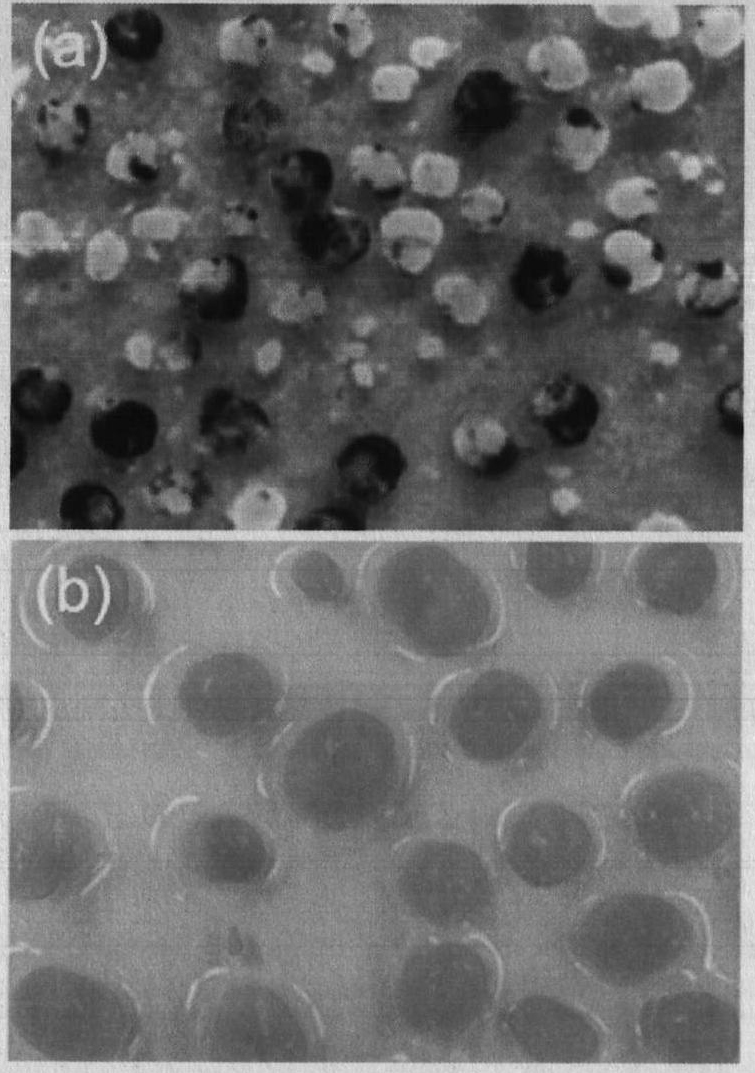

[0023] (1) Granular sludge to be rehabilitated: use influent COD of 250-300mg / L, ammonia nitrogen of 12-15mg / L in a certain urban domestic sewage, with an organic load of 0.9g COD / m 3 Cultivate in a sequencing batch reactor around d, the average particle diameter is 1.5mm, the SVI is 60ml / g, and the biomass is about 4g SS / L (2g SS / L is used as a blank control). White filamentous bacteria can be observed on the surface of the particles with the naked eye.

[0024](2) Bioreactor: The reactor is made of plexiglass, 25cm high, 5cm internal diameter, and 0.5L effective volume. The air enters the reactor through the microporous aeration head placed at the bottom of the reactor by the air pump, and the airflow formed provides the oxygen required for microbial growth and the shear force that is beneficial to the separation of filamentous bacteria on the surface of the particles. The aeration volume during the entire repair process is about 4L / min. The reactor adopts sequential batch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com