Corrosion inhibitor for additive reinforced concrete and preparation method for corrosion inhibitor

A reinforced concrete, additive technology, applied in the field of anti-corrosion materials, can solve the problems of toxic nitrite corrosion inhibitor, pollute the environment, low production cost, etc., and achieve the effects of good biodegradability, low cost, and easy procurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Firstly, sodium molybdate, calcium gluconate, polyaspartic acid and sodium dodecylsulfonate were crushed to 100 mesh respectively, and then sodium molybdate 8%, calcium gluconate 35%, polyaspartic acid Mix the powder of 47% sodium dodecylsulfonate and 10% sodium dodecylsulfonate evenly to get the additive corrosion inhibitor for reinforced concrete.

Embodiment 2

[0025] Firstly, sodium molybdate, calcium gluconate, polyaspartic acid and sodium dodecylsulfonate were crushed to 200 mesh respectively, and then sodium molybdate 5%, calcium gluconate 40%, polyaspartic acid Mix the powder of 40% sodium dodecyl sulfate and 15% sodium dodecylsulfonate evenly to get the additive type corrosion inhibitor for reinforced concrete.

Embodiment 3

[0027] Firstly, sodium molybdate, calcium gluconate, polyaspartic acid and sodium dodecylsulfonate were crushed to 150 mesh respectively, and then sodium molybdate 10%, calcium gluconate 25%, polyaspartic acid Mix 50% sodium dodecylsulfonate powder and 15% sodium dodecylsulfonate powder evenly to get additive corrosion inhibitor for reinforced concrete.

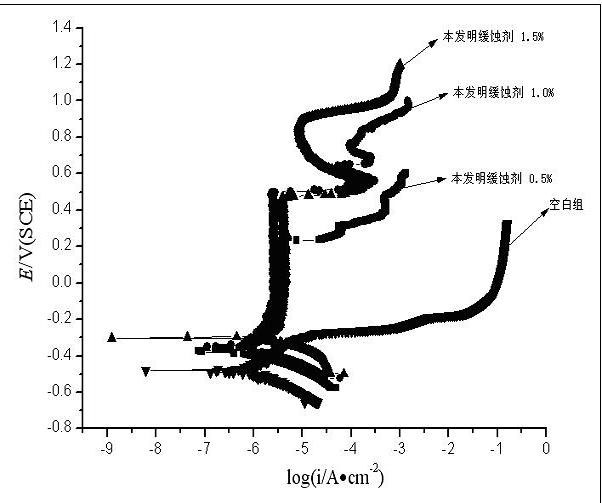

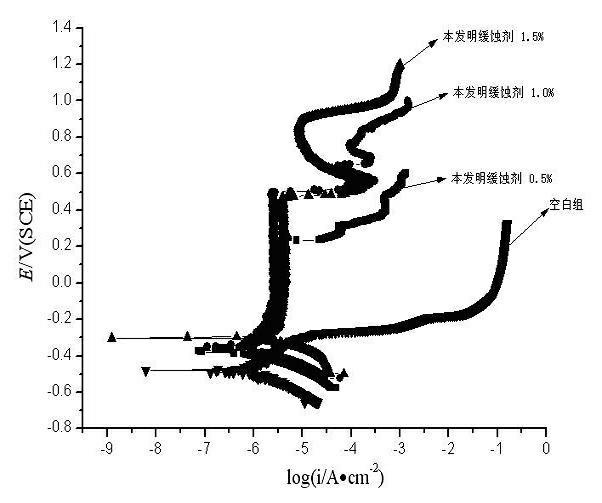

[0028] When the present invention is in use, it is dissolved in water at a weight ratio of 0.5% to 1.5%, and then used in freshly mixed reinforced concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com