Method for preparing automatic-adsorption, ultrathin, anti-peeping and anti-scratching protective film

An anti-scratch, protective film technology, applied in the direction of film/flake adhesive, device for coating liquid on the surface, coating, etc. The film has a large viewing angle and other problems, so as to increase the anti-peep function, prevent peeking and plagiarism, and avoid scratches and abrasions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

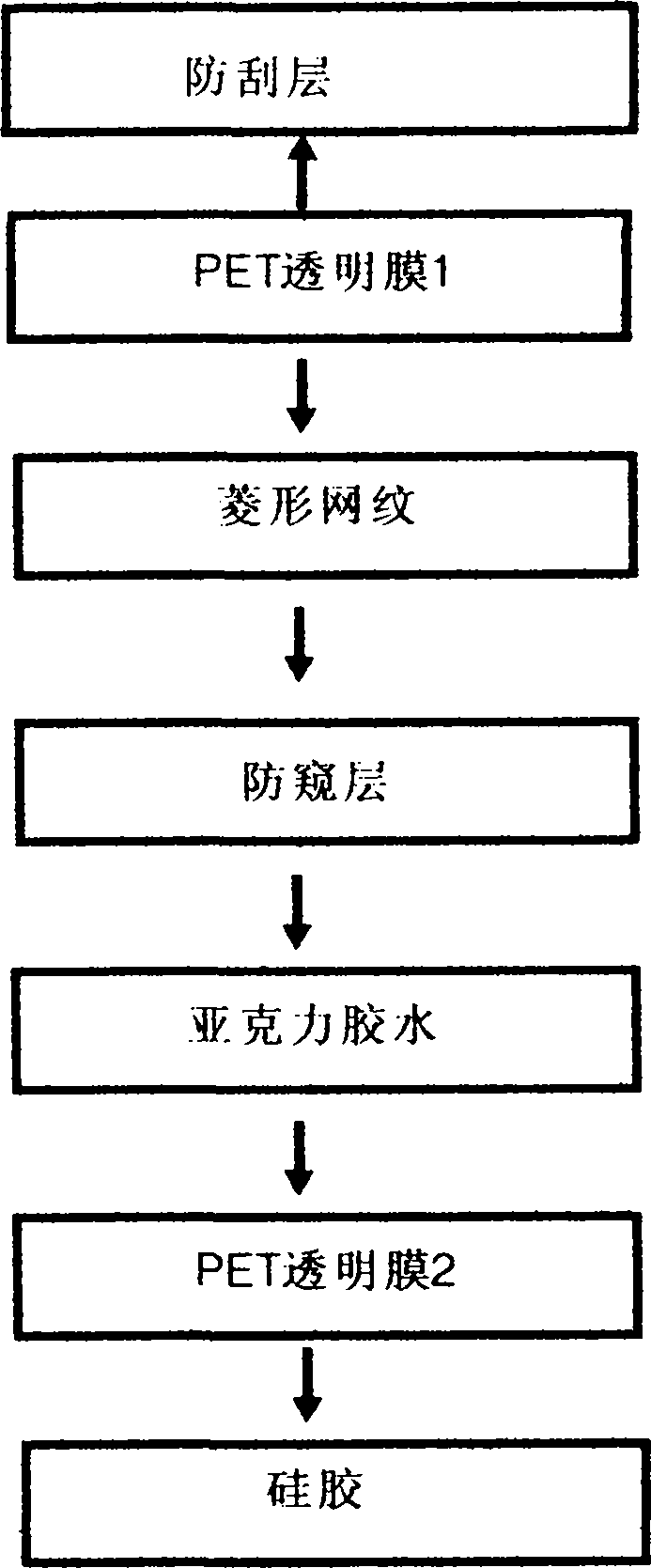

[0008] The present invention consists of a first PET transparent film 1, a second PET transparent film 2, an anti-peeping layer 3, a rhombus texture 4, an anti-scratch layer 5 and an adhesive layer 6. First, the first PET transparent film 1 is coated with a doctor blade. After coating the anti-scratch layer 5, use a gravure roller to coat the diamond-shaped texture 4 on the reverse side of the first PET transparent film, and cure the coated diamond-shaped texture 4 by UV light irradiation, and wait for the diamond-shaped texture 4 to cure Finally, the anti-peep layer 3 is made by coating the curing agent with ultraviolet radiation for the second time on the rhombic pattern 4. After the above steps are completed, the anti-peep layer 3 is bonded to the second PET transparent film 2 with acrylic glue Finally, the silica gel is coated on the other side of the second PET transparent film 2 by means of doctor blade coating, so as to form an automatic adsorption, ultra-thin, anti-peep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viewing angle | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com