Large-scale transformed low-residue fracturing fluid

A technology of fracturing fluid and mass percentage, applied in the field of fracturing fluid, can solve the problems of high suspension sand performance requirements of fracturing fluid, restriction of construction progress, and large construction scale, so as to improve long-term suspension sand performance and reduce construction cost , The effect of enhanced sand-carrying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

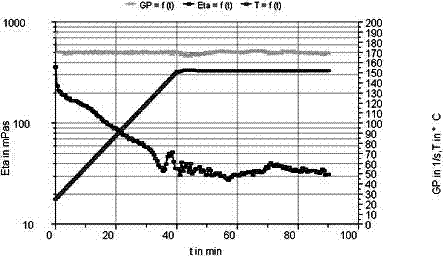

Method used

Image

Examples

Embodiment 1

[0014] Example 1. The low-temperature and low-residue fracturing fluid of this embodiment is mixed with the following components by weight percentage: thickener 0.18%, surfactant 0.06%, demulsifier 0.083%, clay stabilizer 0.4%, bactericide 0.02% %, defoamer 0.02%, gel breaker 0.00066%, gel breaking catalyst 0.0003%, and the balance is water.

Embodiment 2

[0015] Example 2. The fracturing fluid of this embodiment is mixed by the following components by weight percentage: medium and low temperature low residual fracturing fluid, thickener 0.22%, surfactant 0.08%, demulsifier 0.06%, clay stabilizer 0.3% %, 0.02% fungicide, 0.02% defoamer, 0.001% gel breaker, 0.0002% gel breaker catalyst, and the balance is water.

Embodiment 3

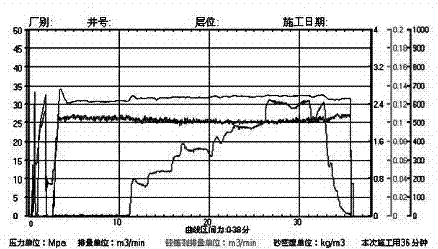

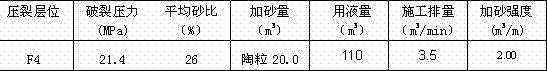

[0016] Example 3. The fracturing fluid of this embodiment is mixed by the following components by weight percentage: medium-temperature low-residue fracturing fluid, 0.30% thickener, 0.12% surfactant, 0.1% demulsifier, and 0.6% clay stabilizer , 0.18% fungicide, 0.09% defoamer, 0.06% gel breaker, 0.0006% gel breaker catalyst, and the balance is water. The fracturing fluid was applied to the F4 layer of well C72-34, which is an ultra-low permeability sandstone reservoir, with a depth of 1241.8-1238.2m and a temperature in the middle of the reservoir of about 67°C. The on-site fracturing operation went smoothly, the average sand ratio reached 26%, the fracturing fluid flowback rate reached 72.9%, and the oil production after reservoir fracturing was 3.95t / d. construction curve see figure 2 , see Table 1 for construction data.

[0017] Construction data of F4 layer of Well C72-34 Table 1

[0018]

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com