Dewaxing method of rice oil

A rice oil and dewaxing technology, which is applied in the fields of edible oil/fat, fat oil/fat refining, and recovery/refining of fatty substances, etc. It can solve the problems of high energy consumption, long production cycle, and large equipment investment in the dewaxing process. Achieve the effects of good dewaxing effect, stable quality and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

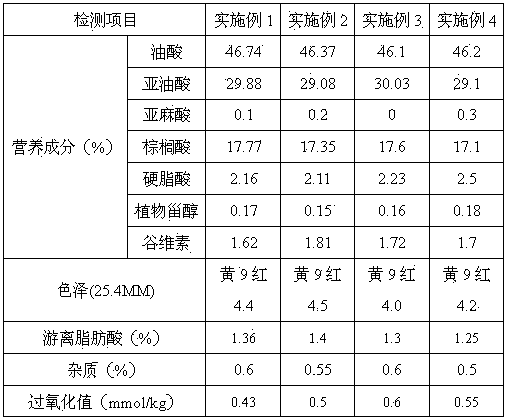

Embodiment 1

[0021] The squeezed or solvent-leached rice oil is filtered to remove suspended impurities, and then the rice oil after conventional degumming, physical deacidification, decolorization and deodorization is heated to 80°C, and then transported to a 25-meter high-level crystallization tank (First heating and then transporting, so that the viscosity of the oil is small and the fluidity is good), start to cool down, gradually reduce the oil temperature from 80°C to 15°C, and control the cooling rate at 5°C / hour, and keep it at 15°C for 25 hours to make The waxy crystals in the edible rice oil are precipitated; the rice oil containing waxy crystals is then used in a crystallization tank to increase the natural pressure difference generated, and the flow rate is controlled to maintain a laminar flow state, and then transported to the wax oil separator to maintain the filter screen. The gap is 5cm, the pore of the stainless steel filter is 1500 mesh, and the pressure is controlled at 2...

Embodiment 2

[0023] The squeezed or solvent-leached rice oil is filtered to remove suspended impurities, and then the rice oil after degumming, physical deacidification, decolorization, and deodorization is heated to 60°C and transported to a 20-meter high-level crystallization tank. Cool down, the oil temperature is gradually reduced from 60°C to 10°C, the cooling rate is controlled at 6°C / hour, and kept at 10°C for 20 hours, so that the waxy crystals in the rice oil will precipitate; then the rice oil containing waxy crystals Use the crystallization tank to increase the natural pressure difference, control the flow rate to keep it in a laminar flow state, and transport it to the wax oil separator to keep the gap between the filters at 3cm. The pores of the stainless steel filter are selected to be 500 meshes and the pressure is controlled at 1.5kg / cm 2 , 10℃ heat preservation, keep the naturally formed wax and oil structure undamaged, filter, the wax content in the separated oil is 4.0 ppm...

Embodiment 3

[0025] The squeezed or solvent-leached rice oil is filtered to remove suspended impurities, and then the rice oil after degumming, physical deacidification, decolorization and deodorization is heated to 50°C and transported to a 15-meter high-level crystallization tank. Cooling down, the oil temperature is gradually reduced from 50°C to 13°C, and the cooling rate is controlled at 4°C / hour, and kept at 13°C for 18 hours to make the waxy crystals in the rice oil precipitate; then the rice containing waxy crystals The oil uses the crystallization tank to increase the natural pressure difference, controls the flow rate to keep it in a laminar state, and transports it to the wax oil separator, keeping the gap between the filters at 4cm. The pores of the stainless steel filter are selected to be 300 meshes, and the pressure is controlled. At 1.0kg / cm 2 , Keep the temperature at 15°C, keep the naturally formed wax and oil structure not damaged, filter, the wax content in the separated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com