Low-carbon high-sulfur free-cutting steel with excellent cutting performance and manufacturing method thereof

A technology of cutting performance and free-cutting steel, applied in the field of free-cutting steel, can solve the problems of poor surface finish of parts, achieve excellent cutting performance, improve thermal processing performance, and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

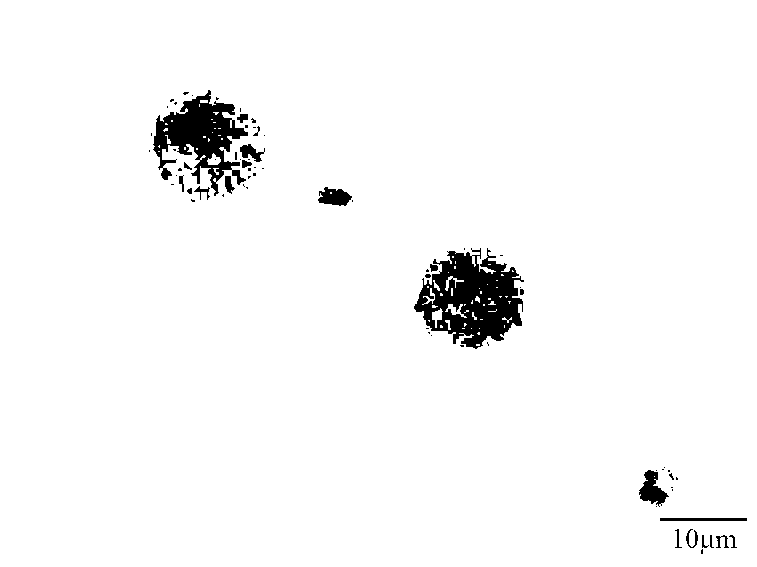

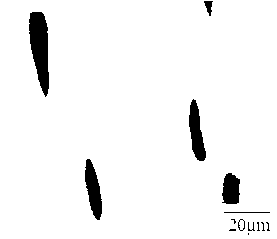

Image

Examples

Embodiment Construction

[0038] The main chemical composition (mass percentage) range of the low-carbon high-sulfur free-cutting steel of the present invention is: C: 0.05-0.2%, Mn: 0.6-2.0%, P: 0.04-0.1%, S: 0.2-0.45%, O : 0.005~0.02%, N≤0.02%, Te: 0.005~0.1%, Si≤0.005%, Al≤0.001%, the rest is Fe and unavoidable impurity elements.

[0039] The manufacture method flow process of the present invention is as follows:

[0040] Steel scrap (or blast furnace molten iron) → induction furnace (or converter or electric furnace) → (LF furnace refining) → die casting (or continuous casting) → rolling → cooling.

[0041] The main processes controlled during the manufacturing process are as follows:

[0042] (1) During induction furnace (or converter or electric furnace) smelting, avoid containing a large amount of Si and Al in scrap steel (or molten iron), and control the raw materials used for smelting to bring in Al, and the mass percentage of Si is Al≤0.0005%, Si≤0.001%, control the carbon content at the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com