Control method for washing quilts by washing machines and full-automatic washing machine

A technology of a fully automatic washing machine and a control method, applied in the field of washing machines, can solve the problems of increasing the turn-to-stop ratio, the quilt is easy to float, and the washing water flow is difficult to penetrate the quilt, etc., and achieves the effect of reducing wear and tear and good washing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

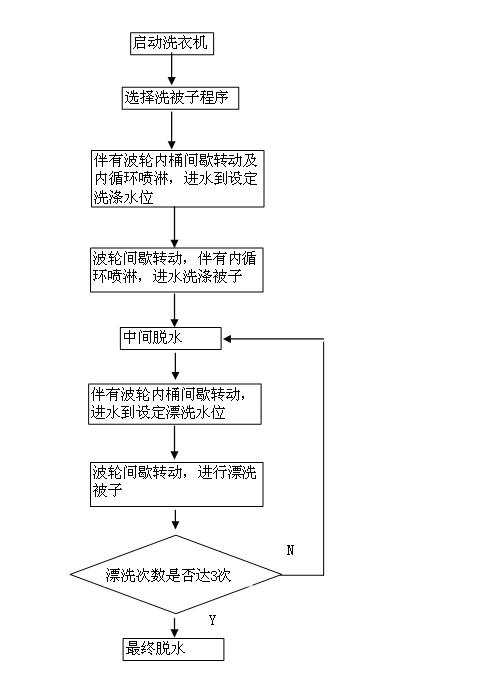

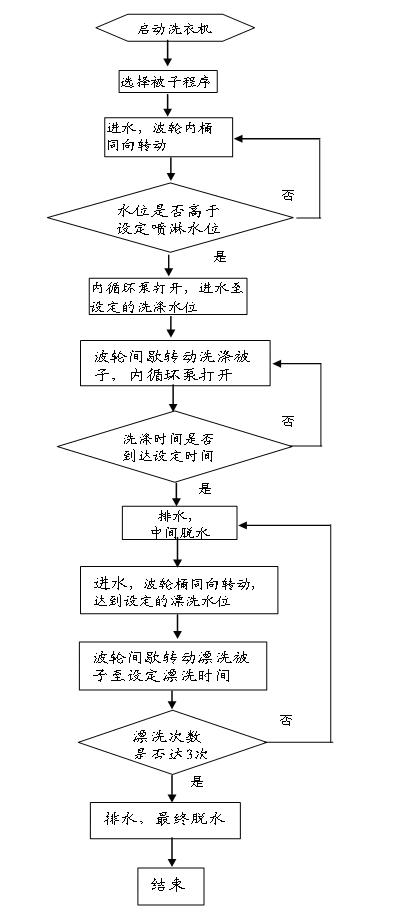

[0024] The control method for washing quilts with a washing machine provided by the present invention and the fully automatic washing machine using the method will be described in detail below in conjunction with the accompanying drawings.

[0025] The present invention is aimed at the quilt in the big thing, and the quilt mainly refers to space cotton, silk cotton, and down quilts whose quilt core materials can be washed. When water enters, the pulsator barrel rotates synchronously and slowly to drive the quilt to rotate to wet the quilt. At the same time, when the water enters a certain time, the water enters to the set spray start water level, then the internal circulation system is opened, and the water enters here. When the set spray start water level is not lower than the minimum water level, the washing water containing washing powder or laundry liquid is pumped up from the bottom and sprayed on the quilt from the upper part, while the quilt is soaked, the fusion of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com