Power-generation-type deceleration strip

A speed bump and power generation technology, applied in the field of power speed speed bump, can solve the problems of effective utilization, loss, waste, etc., and achieve the effects of high power generation efficiency, short transmission path and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

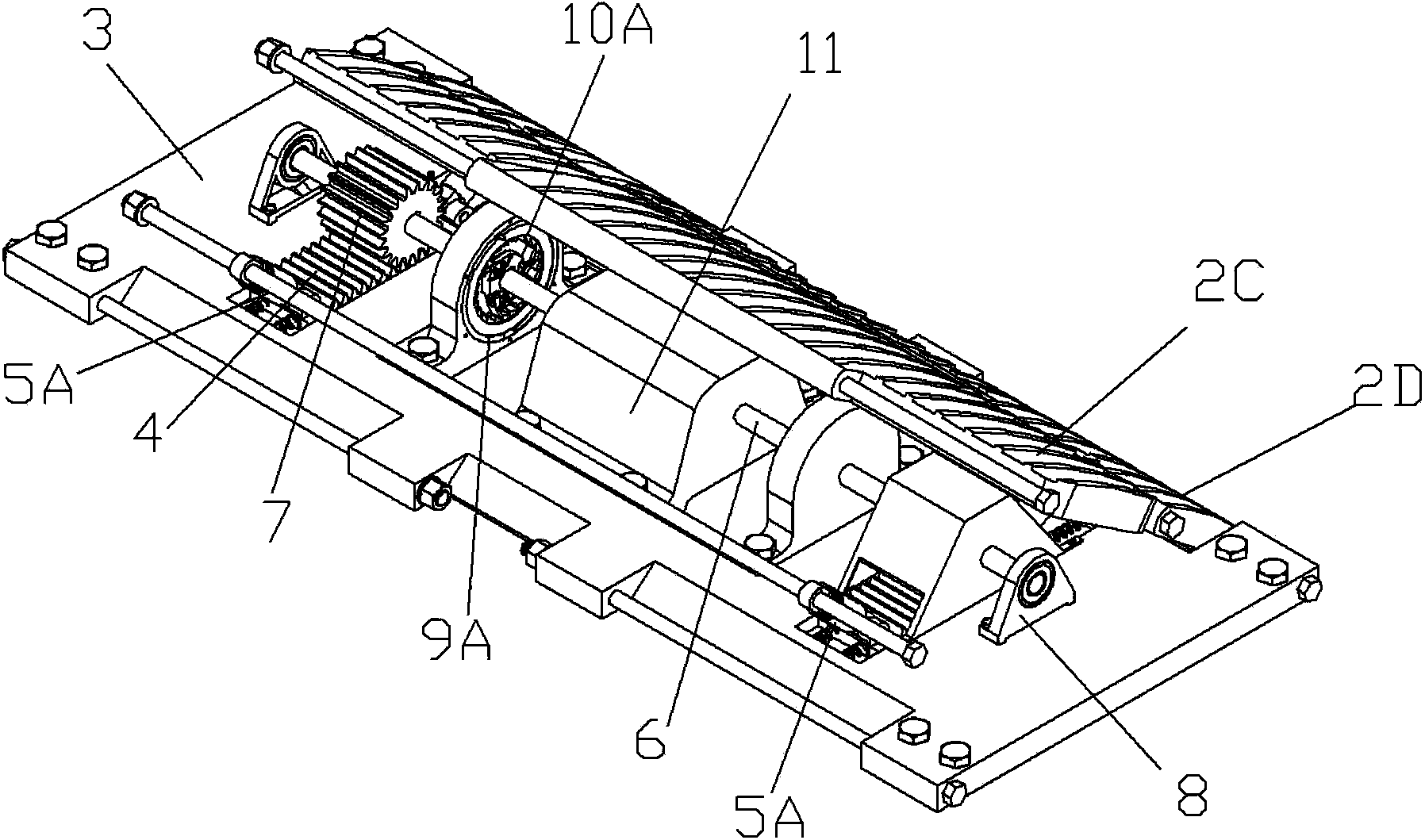

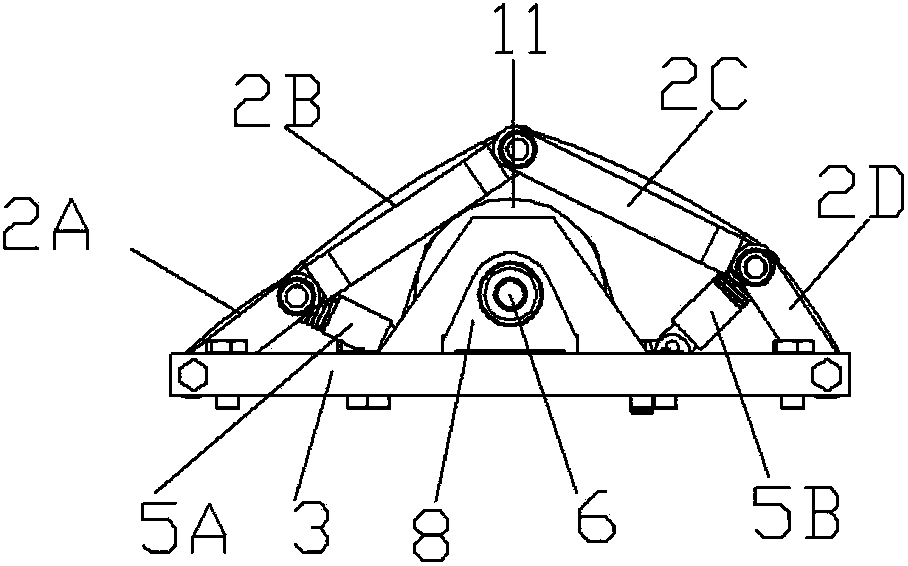

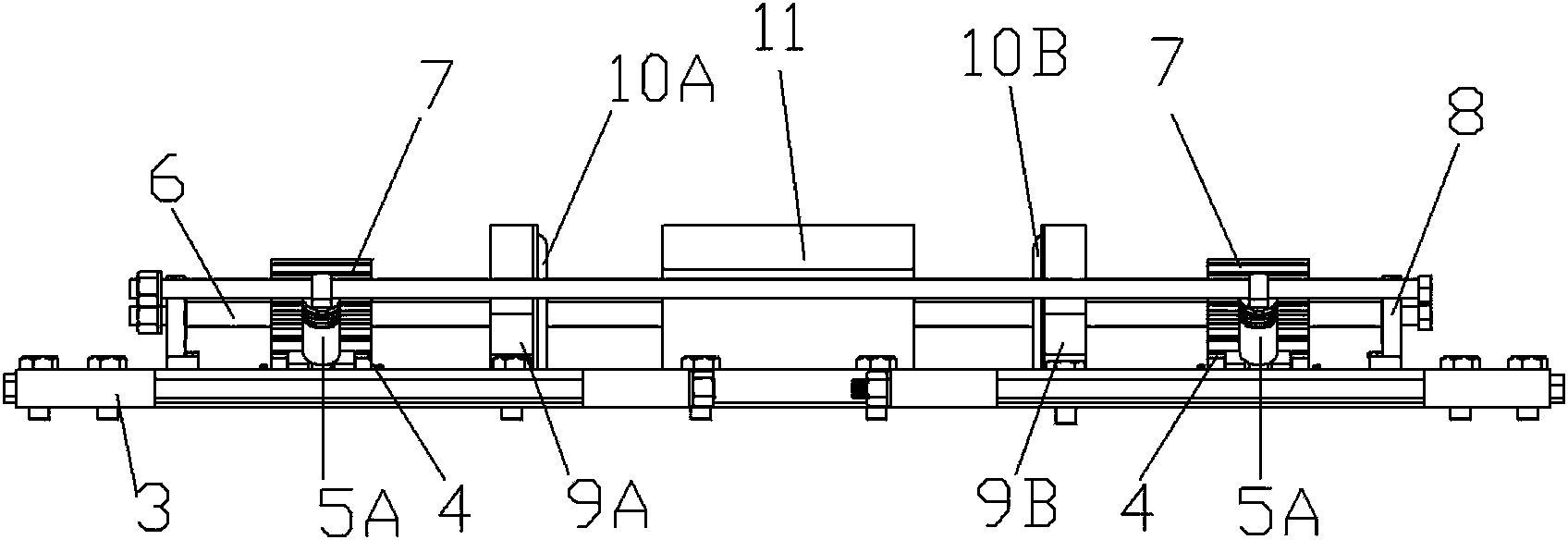

[0018] Figure 1-3 It is shown that a specific embodiment of the present invention is: a power generation speed reduction belt, which is composed of: a grounding plate 3 fixed on the ground, a front cover 2A, a front cover 2B, a rear cover 2C, The back cover-2D is sequentially hinged to form an arched cavity; the ground plate 3 in the cavity is provided with a longitudinal rack 4, and the front end of the rack 4 is connected to the front cover-2A, the front cover through the elastic connector-5A The hinge shaft between the plate two 2B is hinged, and the rear end of the rack 4 is hinged with the hinge shaft between the rear cover one 2D and the rear cover two 2C through the elastic connector two 5B; the rack 4 meshes with the gear 7 above it, so The gear shaft 6 of the gear 7 is installed on the grounding plate 3 through the bearing seat 8;

[0019] The gear shaft 6 is also equipped with an inner meshing ratchet pawl mechanism one 10A and an inner meshing ratchet pawl mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com