Optical reflector with luminous diode lampwick and manufacturing method thereof

A technology of light emitting diodes and optical reflection, applied in the field of light sources, can solve the problems of poor product quality and efficiency consistency, affecting the light distribution quality of lamps, affecting the uniformity of heat dissipation, etc., achieving good consistency, reducing installation procedures and calibration procedures. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, patent of the present invention is described further.

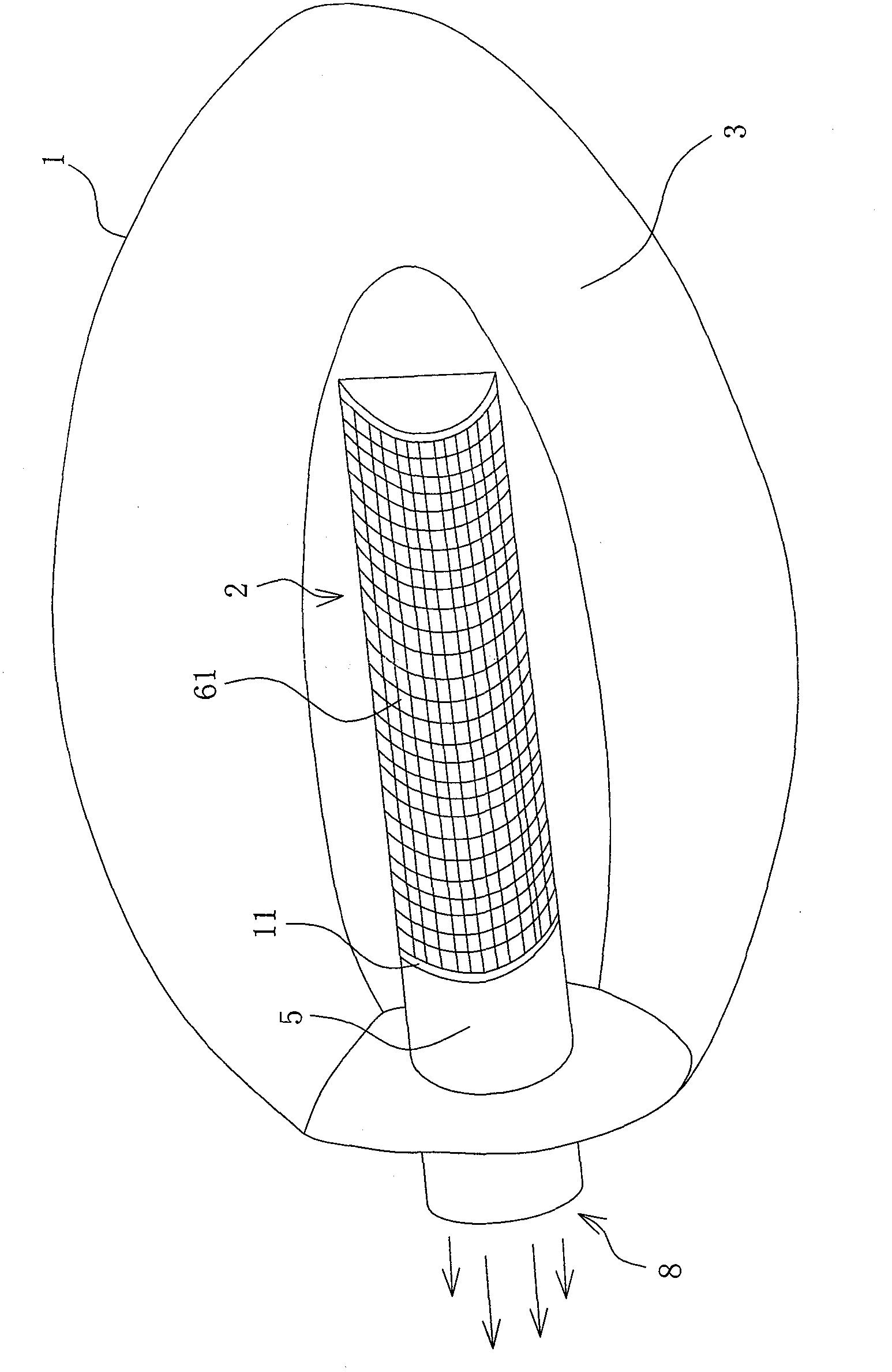

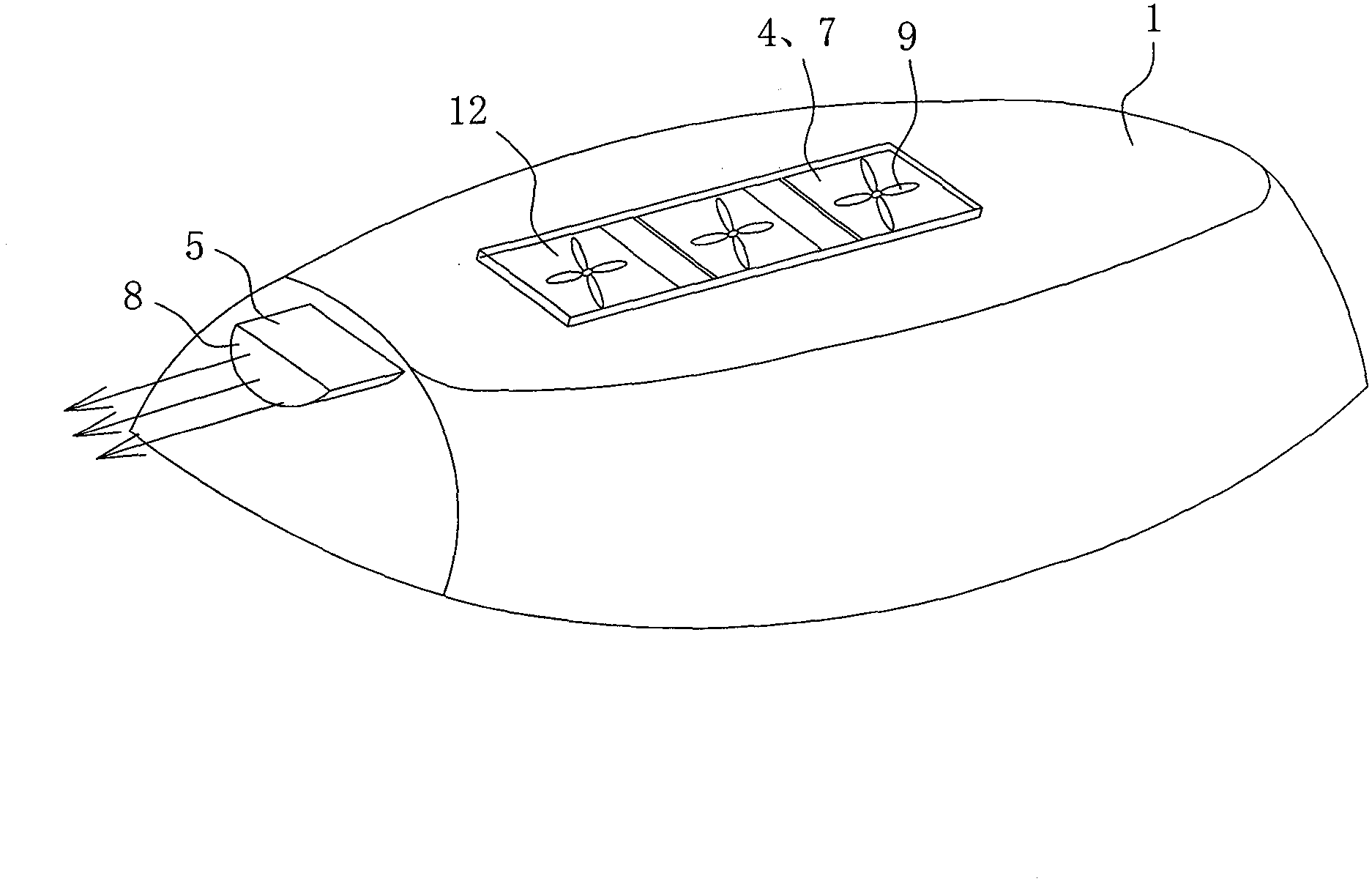

[0024] The optical reflector configured with the LED wick includes a lampshade 1 and the LED wick 2, and the LED wick 2 is installed through a mold on the top of the lampshade inner cavity 3, and the LED wick 2 is a hollow and everted structure. The top of the inner cavity 3 is integrally formed with a light-emitting diode wick support 5 corresponding to the heat dissipation window 4, and the Figure 4 The expressed planar light-emitting diode array module 6 is bent along the shape of the wick holder 5 to form a hollow light-emitting diode wick 2 (such as figure 1 As shown), the wick bracket 5 is also a cooling device bracket. The back of the hollow and everted light-emitting diode wick 2 is an opening structure. The corresponding position is provided with a heat dissipation window 4 communicating with the outside world, the end of the light-emitting diode wick 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com