Self-correcting variable parameter fan coil temperature control method and special equipment

A fan coil unit and special device technology, applied in heating and ventilation control systems, applications, household heating, etc., can solve the problems of lack of management and control methods, temperature fluctuations, large thermal inertia, etc., and achieve good control effect and stable time Fast and stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

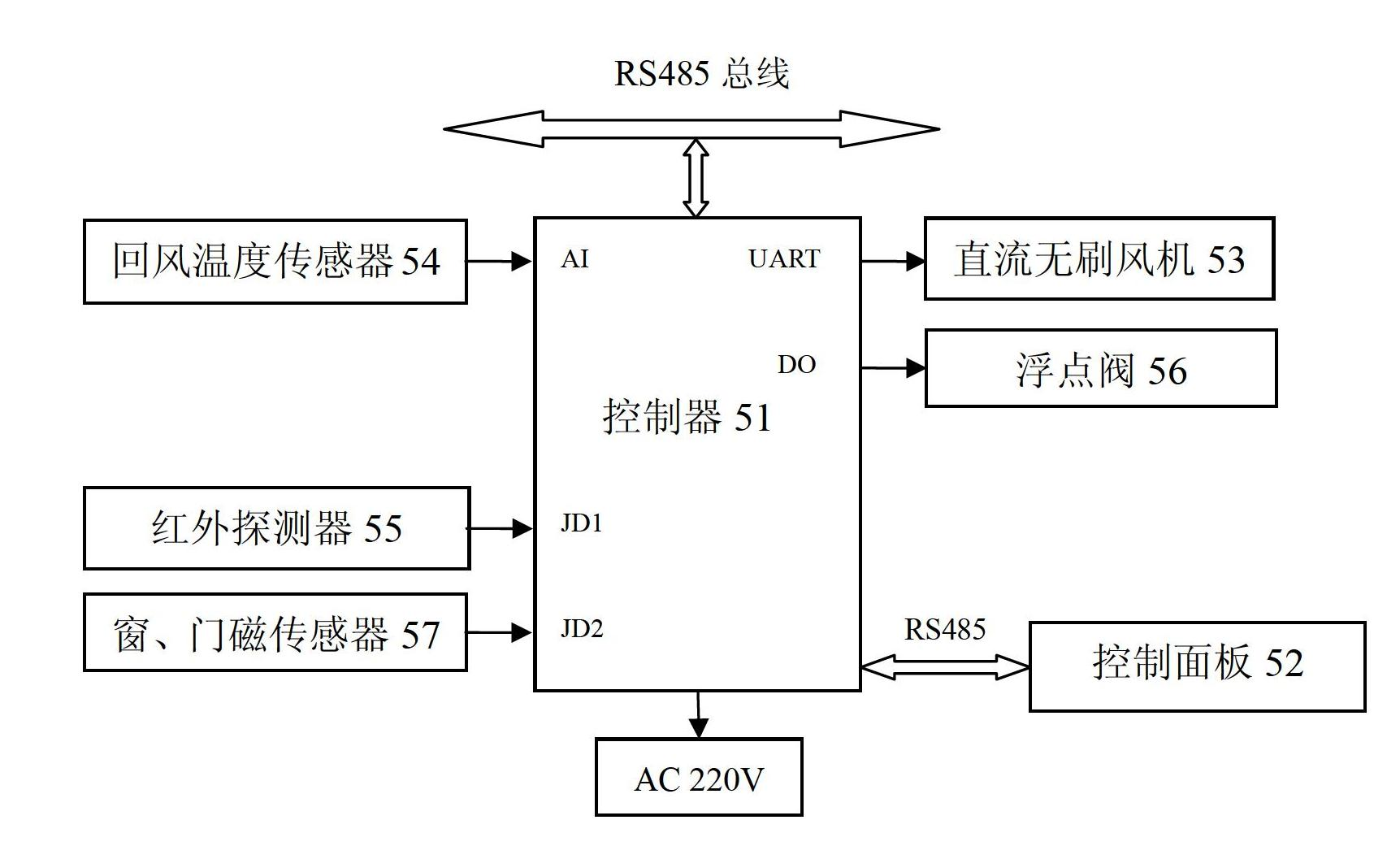

[0049] Figure 1-Figure 10 It constitutes the specific embodiment 1 of the present invention.

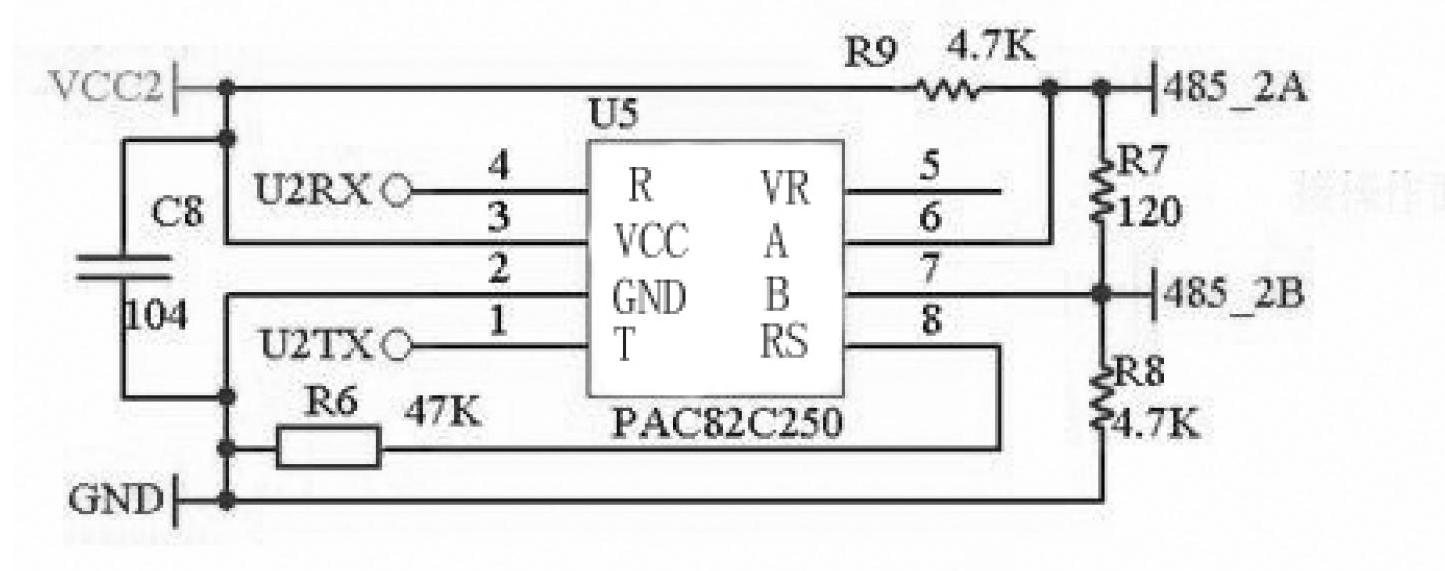

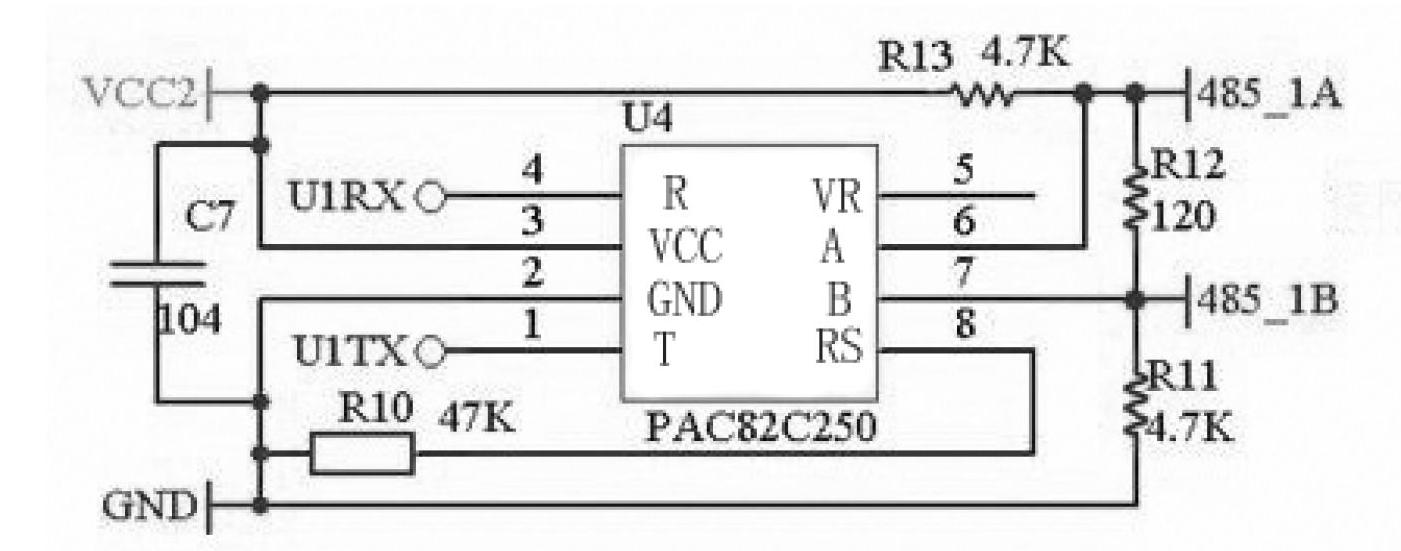

[0050] See figure 1 , The self-correcting variable parameter fan coil temperature control special device involved in this embodiment includes a coil fan circuit, a coil water valve circuit, a control panel 52 and a controller 51. The control panel 52 is equipped with a temperature setting circuit and a display The input / output ports of the circuit, temperature setting circuit and display circuit are connected directly or through the RS485 communication interface to the I / O port of the controller 51. The coil fan circuit is equipped with a DC brushless fan 53 and a return air temperature sensor 54. DC no The control input terminal of the brush fan 53 is connected to one of the control output terminals of the controller 51 through a serial interface, the signal output terminal of the return air temperature sensor 54 is connected to one of the signal input terminals of the controller 51; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com