Waste heat recovery energy-saving cold and heat source system

A waste heat recovery, cold and heat source technology, applied in the direction of heat recovery system, energy-saving heating/cooling, heating and cooling combination, etc., can solve the problems of large boiler footprint, waste of human resources, and aggravated heat island effect, etc., to reduce energy consumption Consumption and operating costs, saving floor space, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

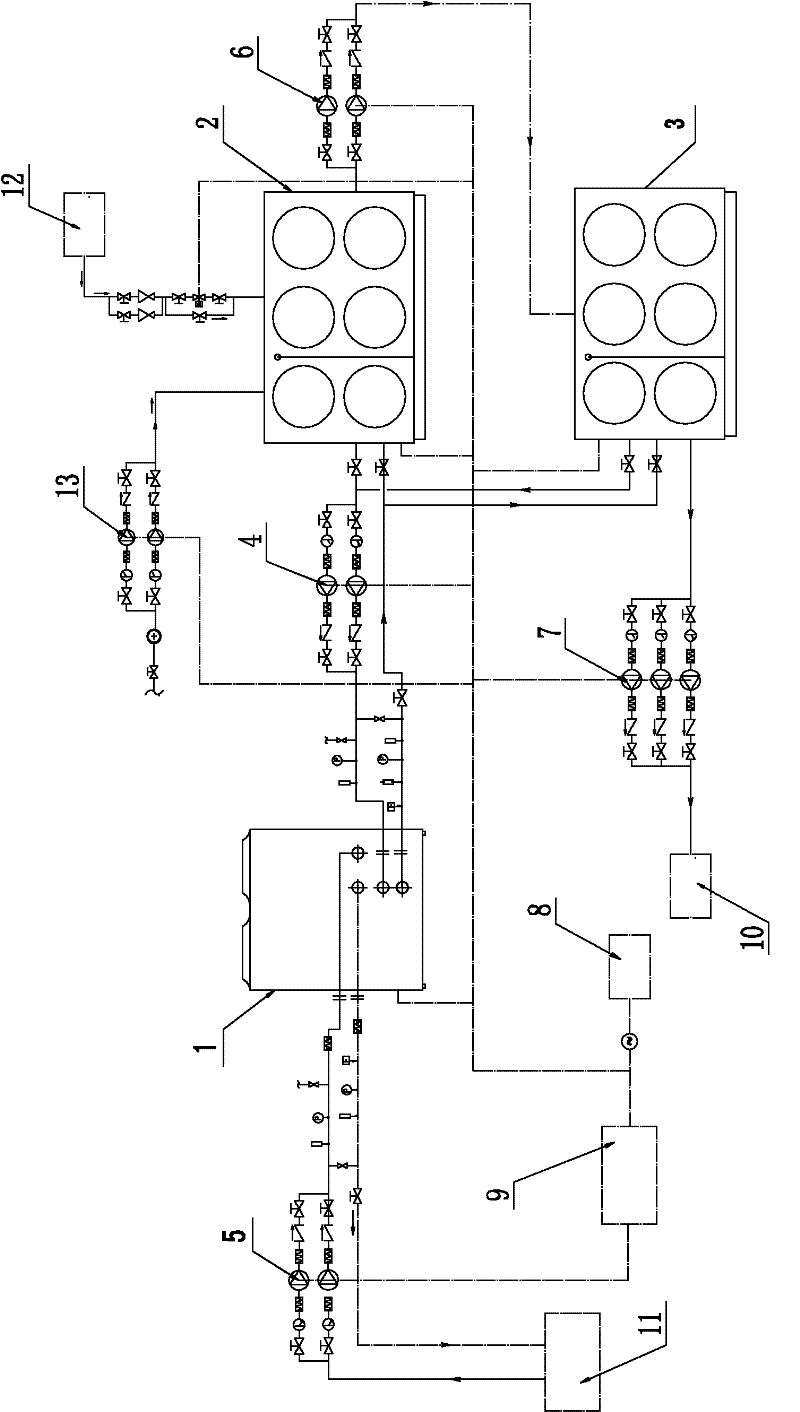

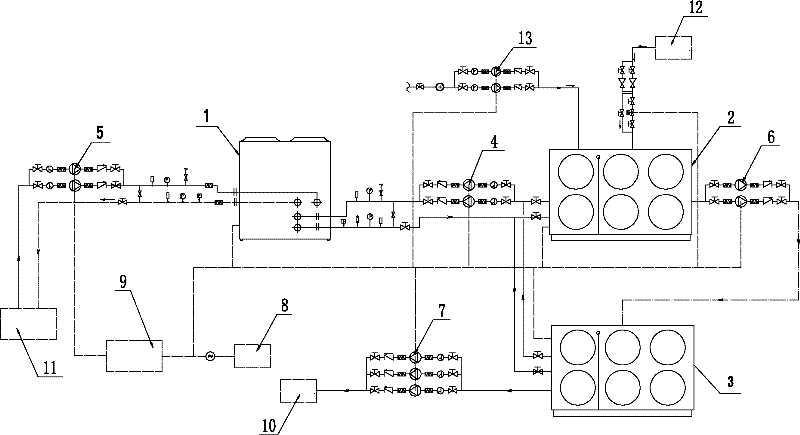

[0012] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0013] As shown in the accompanying drawings, the refrigeration system and the heating system in the present invention are combined into a waste heat recovery and energy-saving cold and heat source system, and the waste heat recovery and energy-saving cold and heat source system includes a cold and heat recovery heat pump unit 1, a stainless steel heating and heat preservation water tank 2, and a stainless steel storage and heat preservation system The output end of the cold and heat recovery heat pump unit 1 described in the water tank 3 and the waste heat recovery automatic electrical control device 9 is respectively piped to the input end of the terminal air conditioning water circulation system 11, the stainless steel heating and thermal insulation water tank 2, and the stainless steel storage thermal insulation water tank 3, and the terminal air conditioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com