Online automatic detection device for strip steel loop decoupling and detection method thereof

An automatic detection device and looper technology, applied in the field of on-line detection of stainless steel strip looper decoupling, and the field of online automatic detection device for stainless steel strip looper decoupling, can solve the problem of reducing product output and quality, failing to detect accidents in time, Damage equipment and other problems, to achieve the effect of improving product quality, simple and reliable detection methods, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

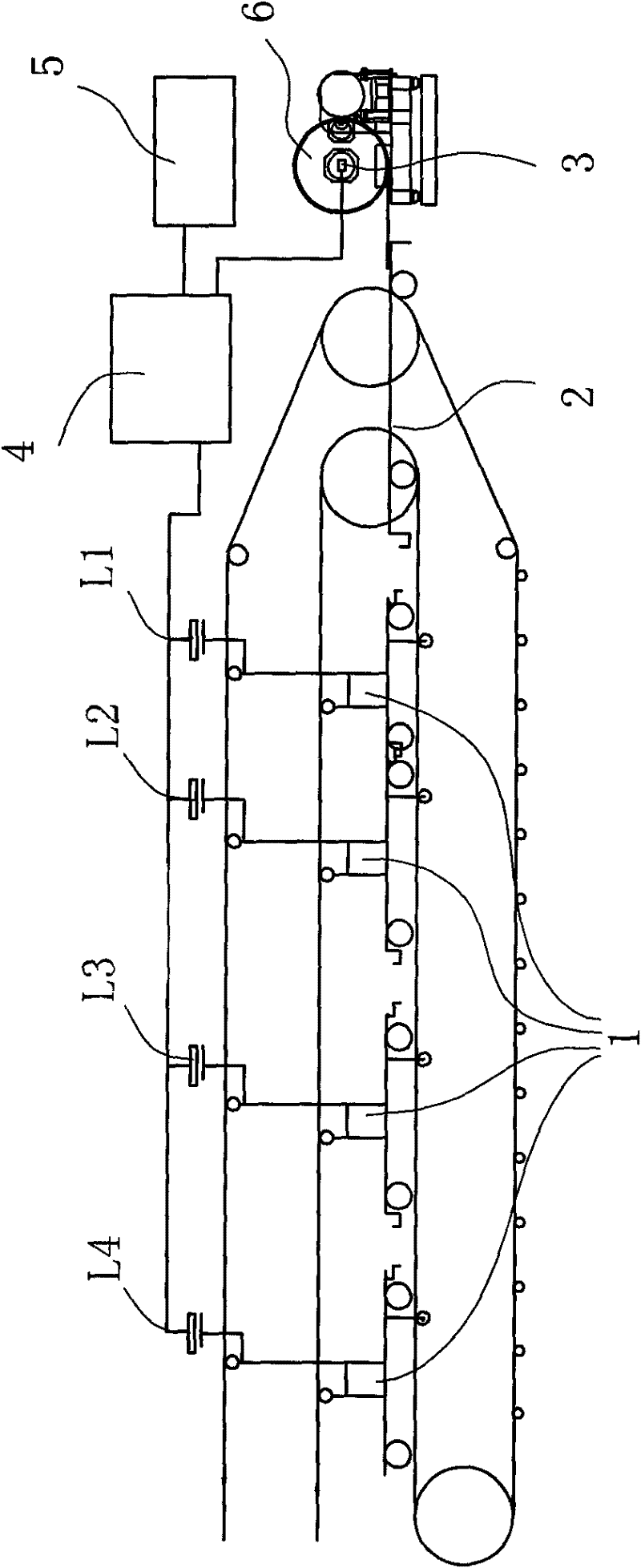

[0026] Such as figure 1 As shown, it is a schematic structural diagram of a 4-layer looper, which is composed of 4 looper trolleys 1 and 1 looper trolley 2, and normal hooking and uncoupling can be realized between each adjacent looper trolley 1 Function, each car is linked to each other in turn according to the design function when flushing the sleeve, and each car is disengaged from each other in turn when closing the sleeve, which is traditional.

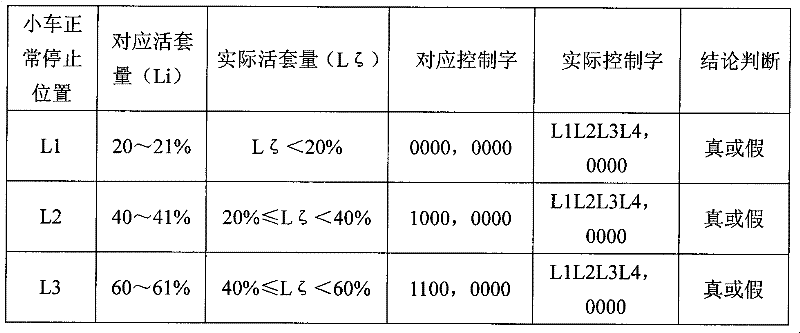

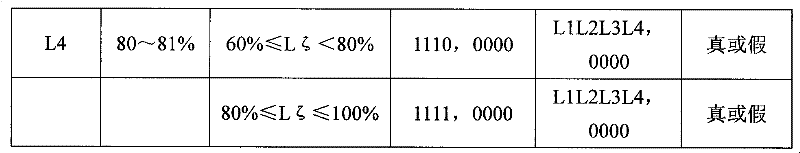

[0027] The rotary encoder 3 is directly installed on the end of the motor drive shaft of the loop hoist 6, and the actual loop amount is the position coordinate of the loop cart 2; the position of each loop trolley 1 corresponds to a certain loop amount Li , when the looper trolley 2 moves to a certain position of the looper trolley, there is always a definite looper trolley 1 in the normal stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com